Sulfur-carbon composite positive electrode material and preparation method and application thereof

A composite material and electrode technology, which is applied in the field of preparation of sulfur/carbon composite positive electrode materials, can solve problems such as limited application and difficulty in breaking through, and achieve the effect of improving practical effects, good adaptability, and simple and environmentally friendly production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

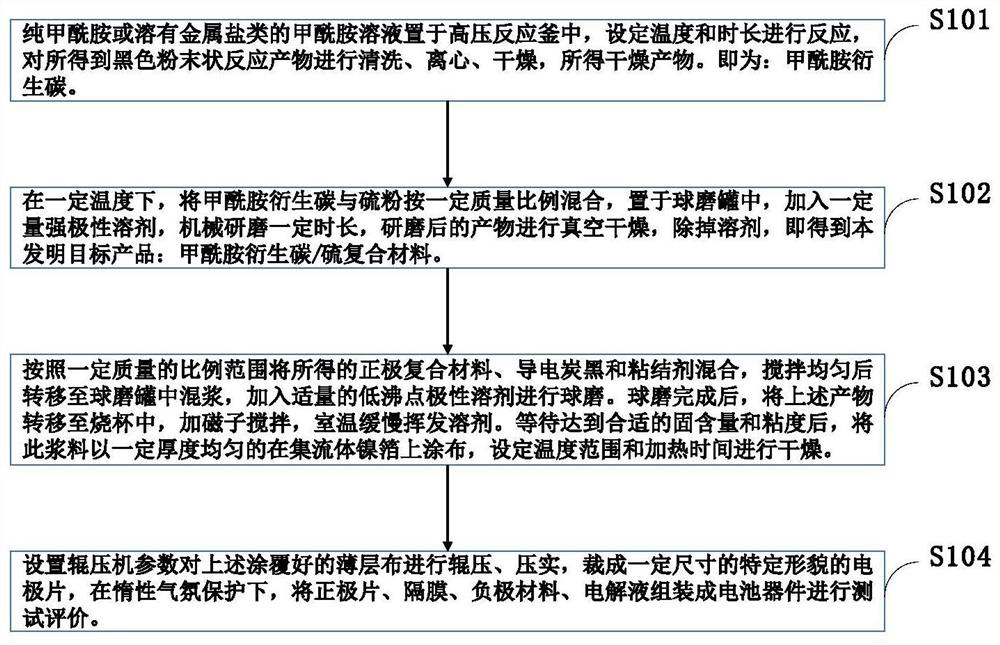

Method used

Image

Examples

Embodiment 1

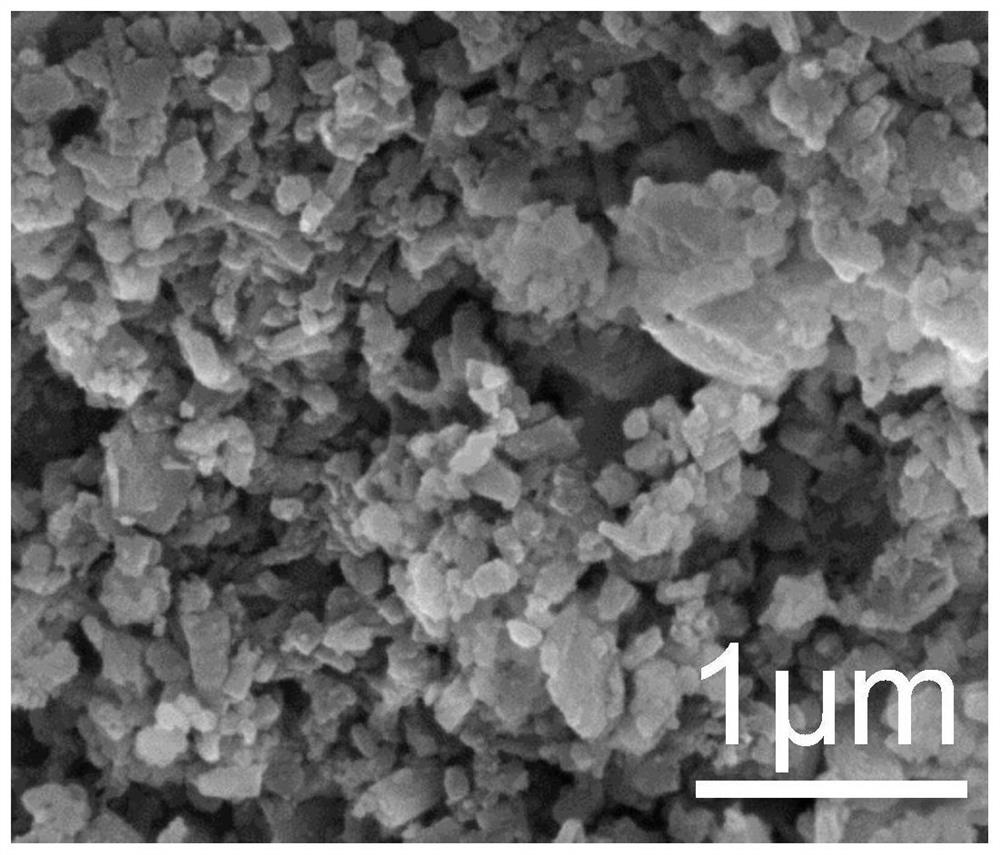

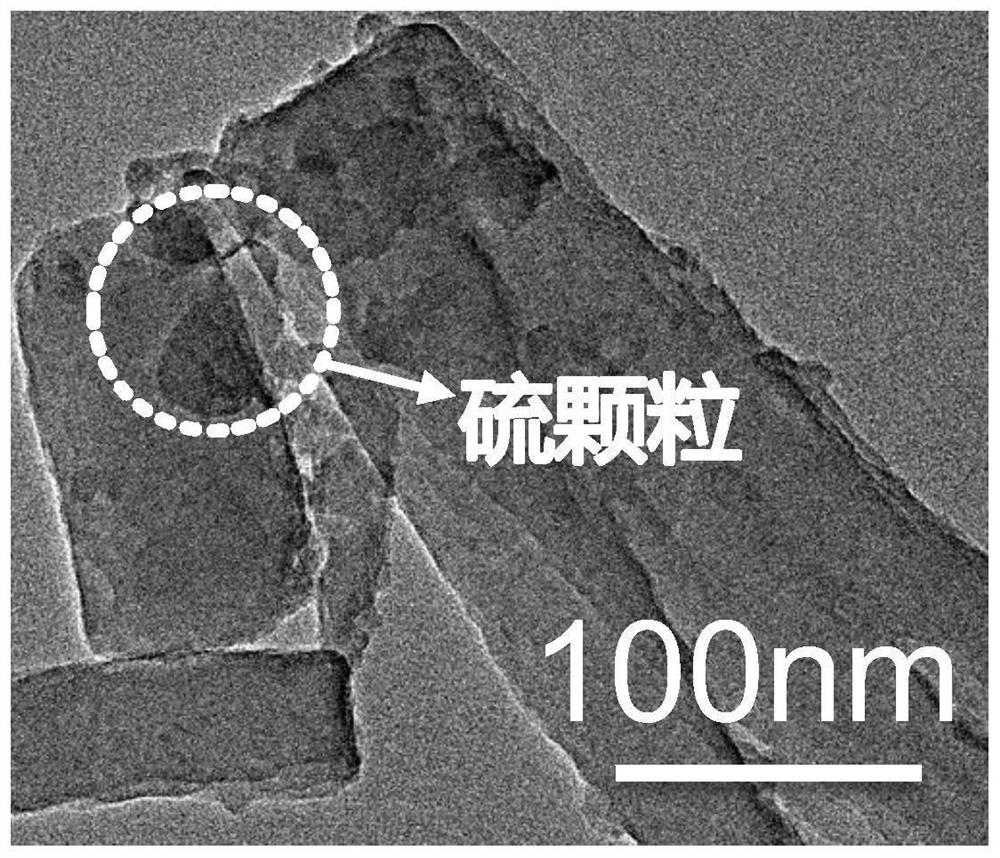

[0053] Measure 30mL of formamide, add it to a 50mL polytetrafluoroethylene liner, seal it, put it into a reactor, and react at 180° for 24 hours. After cooling to room temperature, wash, centrifuge, and dry several times. The polymer material and sublimed sulfur were put into a ball mill jar at a mass ratio of 1:1, and 15 mL of N,N-dimethylformamide was added to ball mill at room temperature for 4 hours, and vacuum dried at 70°C. A cathode material with a sulfur content of 50% was obtained. According to the positive electrode material: conductive carbon black: binder (LA132) = 7:2:1 mixing slurry.

Embodiment 2

[0055] Add 1g of zinc chloride to 30mL of formamide, disperse evenly by ultrasonic, add to 50mL of polytetrafluoroethylene liner, seal it and put it into a reaction kettle, and react at 180° for 24 hours. After cooling to room temperature, wash, centrifuge, and dry several times. The polymer material and the sublimed sulfur were put into a ball mill jar at a mass ratio of 3:7, and 15 mL of N,N-dimethylformamide was added for ball milling at room temperature for 4 hours, followed by vacuum drying at 70°C. A positive electrode material with a sulfur content of 70% was obtained. According to the positive electrode material: conductive carbon black: binder (LA132) = 7:2:1 mixing slurry.

Embodiment 3

[0057] The operation steps are the same as in Example 2, except that 1.0 g of zinc chloride in the raw material is replaced by 1.0 g of molybdenum chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap