Dry-mixed mortar prepared from titanium extraction tailings

A technology for extracting titanium tailings and dry-mixed mortar, which is applied in the field of building materials, can solve the problems of low fly ash early activity, reduced fly ash output, and short supply, so as to avoid increased water consumption, enhance mechanical properties, and improve The effect of work performance

Inactive Publication Date: 2020-12-01

PANGANG GRP ENG TECH

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At the same time, at present, cement, sand, and fly ash are still mainly used in the preparation of dry-mixed mortar in most areas of the country. However, with the reduction of thermal power generation, the output of fly ash has begun to decrease significantly, and the supply of fly ash has been in short supply in some areas. The low early activity makes the early strength of mortar low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

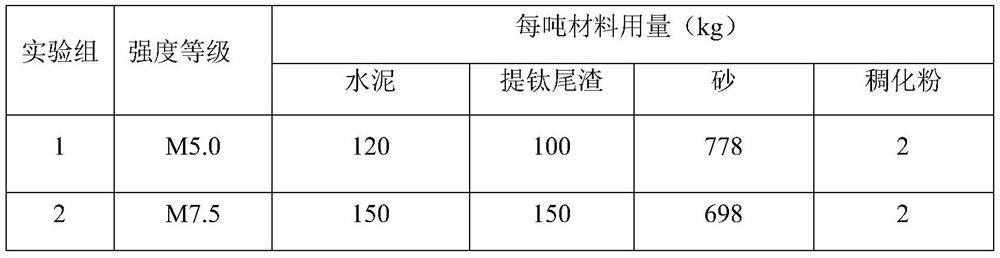

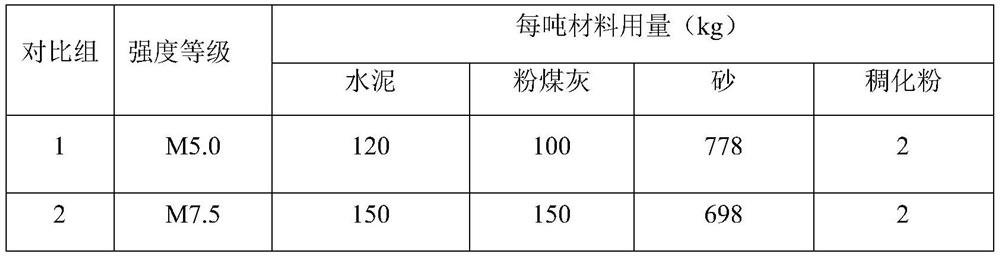

[0028] The present invention provides two groups of dry-mixed mortars for extracting titanium tailings and two groups of comparison examples for general dry-mixed mortars. The specific ratios are shown in Table 1 and Table 2 below:

[0029] Table 1 Component distribution ratio of titanium tailings dry-mixed mortar

[0030]

[0031] Table 2 Component ratio of general dry-mixed mortar

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of building materials, and particularly relates to dry-mixed mortar prepared from titanium extraction tailings. The invention provides the dry-mixed mortarprepared from titanium extraction tailings aims to overcome technical problems in the prior art. The dry-mixed mortar comprises the following components in parts by mass: 120-200 parts of cement, 90-160 parts of the titanium extraction tailings, 680-800 parts of sand and 2-3 parts of thickening powder. The industrial solid waste, namely the titanium extraction tailings are used in the dry-mixed mortar, the performance indexes such as the water retention rate, the strength grade, the softening coefficient and the maximum water absorption rate of the obtained dry-mixed mortar meet standard requirements, the strength grade and the water retention rate are superior to the strength grade and the water retention rate of common dry-mixed mortar, and the dry-mixed mortar can be widely applied toactual production.

Description

technical field [0001] The invention belongs to the technical field of building materials, and in particular relates to a dry-mixed mortar for extracting titanium tailings. Background technique [0002] After Panzhihua Iron and Steel's high-titanium blast furnace slag extracts titanium, 85% of the total blast furnace slag will become new titanium extraction tailings. Due to the high content of chloride ions in the tailings of titanium extraction, the fineness is reduced, so it is no longer suitable for concrete sand and gravel materials. Although the tailings from titanium extraction can be stockpiled as Class II general industrial solid waste, it will increase the land occupation of the slag yard, increase industrialization investment and operating costs, and affect the environment. One of the main factors affecting the industrialization of blast furnace slag is to develop economical and comprehensive utilization technologies for titanium extraction tailings, realize large...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04

CPCC04B28/04C04B2201/50C04B18/144C04B14/06C04B2103/44

Inventor 陈治科赵钰杰钱宝军

Owner PANGANG GRP ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com