Putty surface decoration material and its preparation method and use method

A decorative material, putty surface technology, applied in the direction of filling slurry, etc., can solve the problems of unadjusted construction performance of putty, limited removal of formaldehyde and harmful substances, poor indoor formaldehyde removal effect, etc., to achieve excellent construction performance, anti-sag Good performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

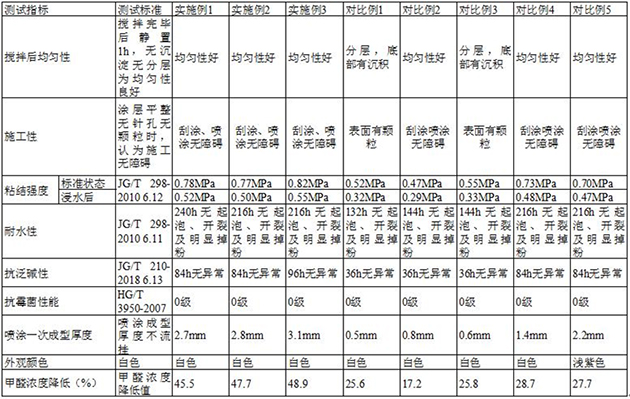

Examples

preparation example Construction

[0076] The preparation method of manganese dioxide-loaded diatomite is as follows: immersing diatomite into potassium permanganate solution; adding citric acid complexing agent, adjusting pH between 5 and 6, then ultrasonically dispersing, drying and grinding, After grinding, it is heated in a muffle furnace, then cooled to room temperature, taken out, stirred evenly, and then dispersed by ultrasonic to obtain manganese dioxide-supported diatomite.

[0077] It is understood that the binder can be selected from inorganic binders and / or organic binders.

[0078] Preferably, the inorganic base material is white cement. After the calcium oxide in the white cement is hydrated, it can form a strong alkaline material and increase the positive and negative ion groups in the air.

[0079] Preferably, the organic base material is polymer latex powder. Polymer latex powder can make the coating of putty more dense, improve the bonding strength, water and moisture resistance of putty, an...

Embodiment 1

[0106] The present embodiment provides a putty surface decoration material and its preparation method and application, and the steps are as follows:

[0107] 1) Prepare the raw materials according to the following parts by weight

[0108] 4 parts of polymer latex powder, 15 parts of white cement, 25 parts of heavy calcium, 13 parts of spherical silica powder, 20 parts of manganese dioxide-supported diatomaceous earth, 10 parts of nano-titanium dioxide, 7.5 parts of alumina, 3 parts of calcium carbonate whiskers, 0.5 part of hydroxypropyl methyl cellulose ether, 0.5 part of defoamer, 1 part of water repellent, 0.5 part of antifungal agent.

[0109] 2) Preparation method

[0110] The polymer latex powder, white cement, heavy calcium, spherical silica powder, manganese dioxide supported diatomaceous earth, nano-titanium dioxide, alumina, calcium carbonate whiskers, hydroxypropyl methyl cellulose ether, defoamer, hydrophobic Pour the antifungal agent and the antifungal agent int...

Embodiment 2

[0114] The present embodiment provides a putty surface decoration material and a preparation method and application thereof, which are basically the same as those in Embodiment 1, except that the amount of raw materials is different, and the steps are as follows:

[0115] 1) Prepare the raw materials according to the following parts by weight

[0116] 4 parts of polymer latex powder, 15 parts of white cement, 18 parts of heavy calcium, 8 parts of spherical silica powder, 30 parts of manganese dioxide supported diatomaceous earth, 7.5 parts of nano-titanium dioxide, 10 parts of alumina, 5 parts of calcium carbonate whiskers, 0.5 part of hydroxypropyl methyl cellulose ether, 0.5 part of defoamer, 1 part of water repellent, 0.5 part of antifungal agent.

[0117] 2) Preparation method

[0118] The polymer latex powder, white cement, heavy calcium, spherical silica powder, manganese dioxide supported diatomaceous earth, nano-titanium dioxide, alumina, calcium carbonate whiskers, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com