Polylactic acid biodegradable wall decoration material and preparation method thereof

A technology of wall decoration and polylactic acid, applied in fabric surface trimming, chemical instruments and methods, dyeing methods, etc., can solve problems such as poor heat resistance, difficulty in textile and dyeing and finishing processing, poor heat resistance and processing performance, and achieve durability Good abrasiveness, soft and straight feel, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

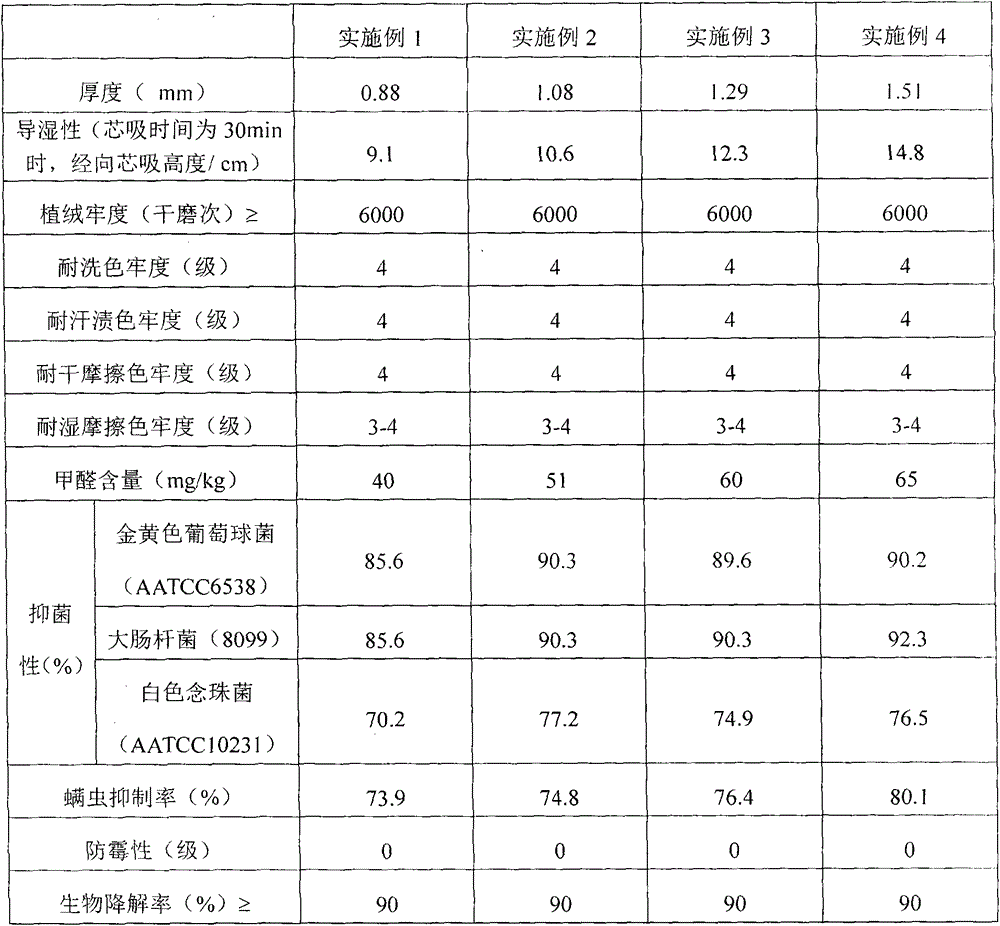

Examples

Embodiment 1

[0028] 1. Selection of fiber and base material:

[0029] Select the white polylactic acid fiber filament bundle with a linear density of 2D, and select the polylactic acid fiber woven base fabric with a grammage of 80g / m 2 Polylactic acid fiber woven fabric.

[0030] 2. Preparation method:

[0031] 1) Dyeing the polylactic acid fiber filament bundle, the steps are:

[0032] A. Dissolving dye auxiliaries at 40°C, the dyeing bath consists of DianixBlueXF low-temperature disperse dye 1% (based on fabric weight), leveling and dispersing agent 1g / L, penetrating agent 0.5g / L, bath ratio 1:30, add Glacial acetic acid adjustment solution pH value is 5;

[0033] B. Start to heat up to 70°C at a rate of 3°C / min, then raise the temperature to 100°C at a rate of 2°C / min, keep warm at 100°C for 30 minutes, then cool down to 50°C at a rate of 2°C / min, and release water;

[0034] C. Carry out reducing water washing, the conditions are: sodium bicarbonate 1g / L, sodium bicarbonate 1g / L, ba...

Embodiment 2

[0041] 1. Selection of fiber and base material:

[0042] Select the white polylactic acid fiber filament bundle with a linear density of 3D, and select the polylactic acid fiber woven base fabric with a grammage of 150g / m 2 Polylactic acid fiber woven fabric.

[0043] 2. Preparation method:

[0044] 1) Dyeing the polylactic acid fiber filament bundle, the steps are:

[0045] When A. 40 DEG C, dissolve the dye auxiliaries, the dyeing bath is composed of DianixBlueXF low-temperature disperse dye 1.2% (based on fabric weight), leveling and dispersing agent 1.3g / L, penetrating agent 0.6g / L, liquor ratio 1: 25, Add glacial acetic acid to adjust the pH of the solution to be 5;

[0046] B. Start to heat up to 70°C at a rate of 3°C / min, then raise the temperature to 100°C at a rate of 2°C / min, keep warm at 102°C for 30 minutes, then cool down to 50°C at a rate of 2°C / min, and release water;

[0047] C. Carry out reducing water washing, the conditions are: sodium bicarbonate 1.2g / L, ...

Embodiment 3

[0054] 1. Selection of fiber and base material:

[0055] Choose white polylactic acid fiber filament bundles with a linear density of 4D, and the polylactic acid fiber woven base fabric has a grammage of 220g / m 2 Polylactic acid fiber woven fabric.

[0056] 2. Preparation method:

[0057] 1) Dyeing the polylactic acid fiber filament bundle, the steps are:

[0058] A. Dissolving dye auxiliaries at 40°C, the dyeing bath consists of 2% DianixBlueXF low-temperature disperse dyes (based on fabric weight), leveling and dispersing agent 1.8g / L, penetrating agent 1g / L, bath ratio 1:25, add Glacial acetic acid adjustment solution pH value is 5.2;

[0059] B. Start to heat up to 70°C at 2°C / min, then heat up to 100°C at 1°C / min, keep warm at 105°C for 40 minutes, then cool down to 50°C at 2°C / min, and release water;

[0060] C. Carry out reducing water washing, the conditions are: sodium bicarbonate 1.8g / L, sodium bicarbonate 1.8g / L, bath ratio 1:25, temperature rises to 65°C, reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com