Processing technology of fiber-plastic reinforced composite winding pipe and product thereof

A technology for enhancing compounding and processing technology, applied in the direction of tubular articles, pipes, rigid pipes, etc., can solve the problems of insufficient connection stability, fiber reinforced layer falling off, poor strength, etc., to ensure service life, low production cost, and production. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

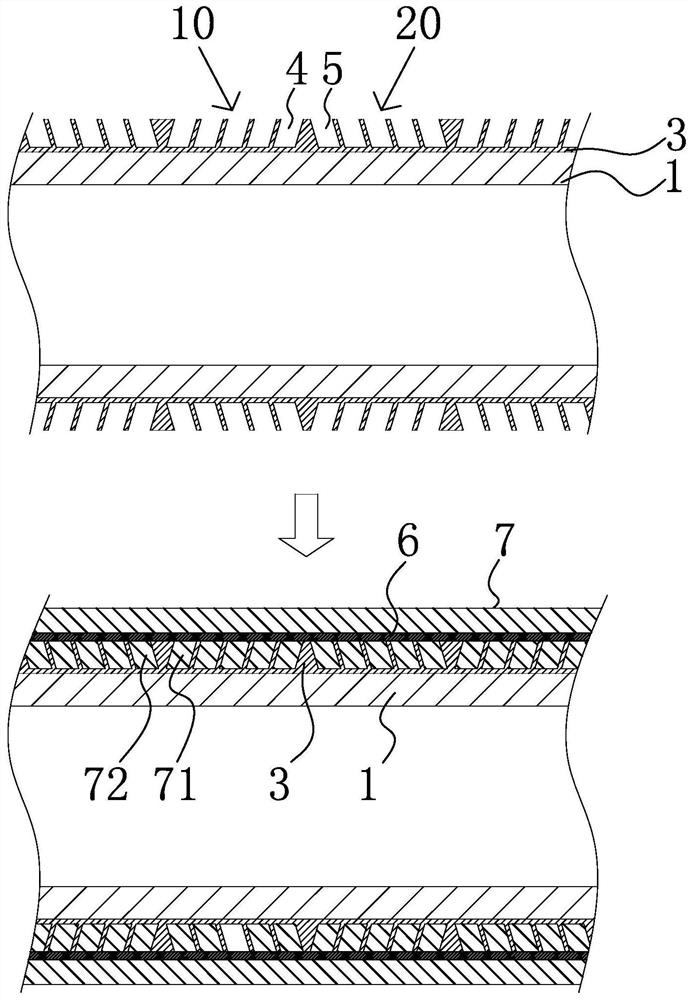

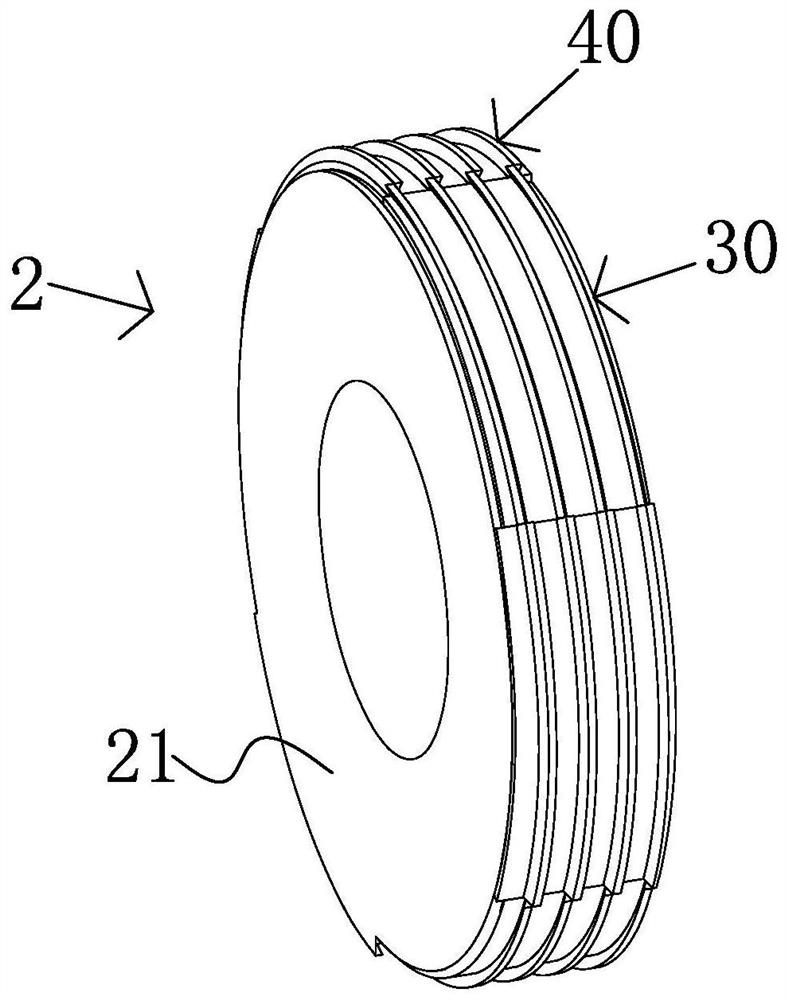

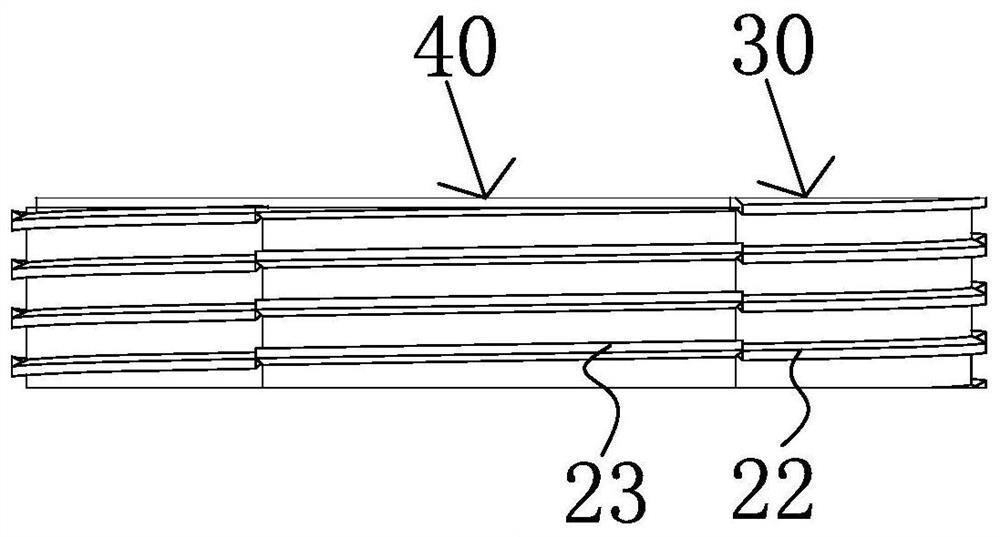

[0035] refer to figure 1 , a processing technology of fiber-plastic reinforced composite winding pipe, comprising the following steps:

[0036] Step 1, prepare the pipe material, which can be PE, PP or PVC, heat the pipe material to 150°C-300°C to melt, pour it into the mold and cool it to form a strip; in addition, in this embodiment , the pipe material is preferably PE;

[0037] Step 2: The strips are spirally wound and connected to form the pipeline main body 1; in addition, the edges of the strips are provided with PE material for connection, and the PE material can be formed at the same time when the strips are formed. When connecting, the edges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com