Stress field measurement method based on ultrasonic tomography

A technology of ultrasonic tomography and measurement methods, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of long measurement time and high quality requirements of operators, achieve long measurement time and improve measurement efficiency , the effect of reducing requirements

Active Publication Date: 2020-12-01

四川中创辰安检测技术有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, the existing ultrasonic residual stress measurement technology adopts single-point measurement. To realize the stress distribution measurement on the shallow surface of the workpiece, a mechanical device is often used to move the measurement probe to realize the measurement of different measurement points. The quality of the operator is required to be high, so the rapid and non-destructive measurement of the stress field distribution on the shallow surface of the workpiece has great engineering application value

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

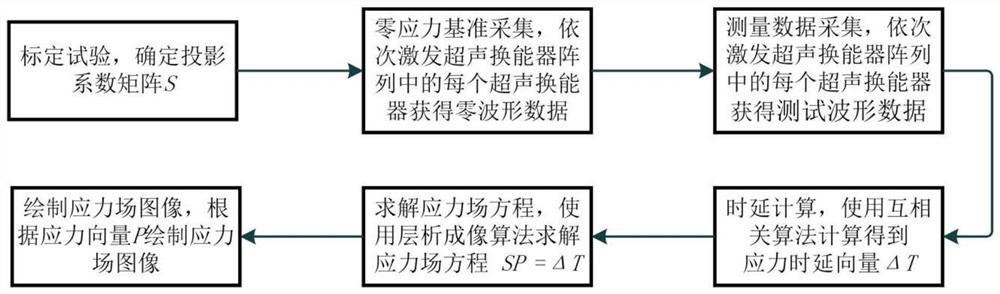

[0046] A method for measuring a stress field based on ultrasonic tomography provided in this embodiment includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

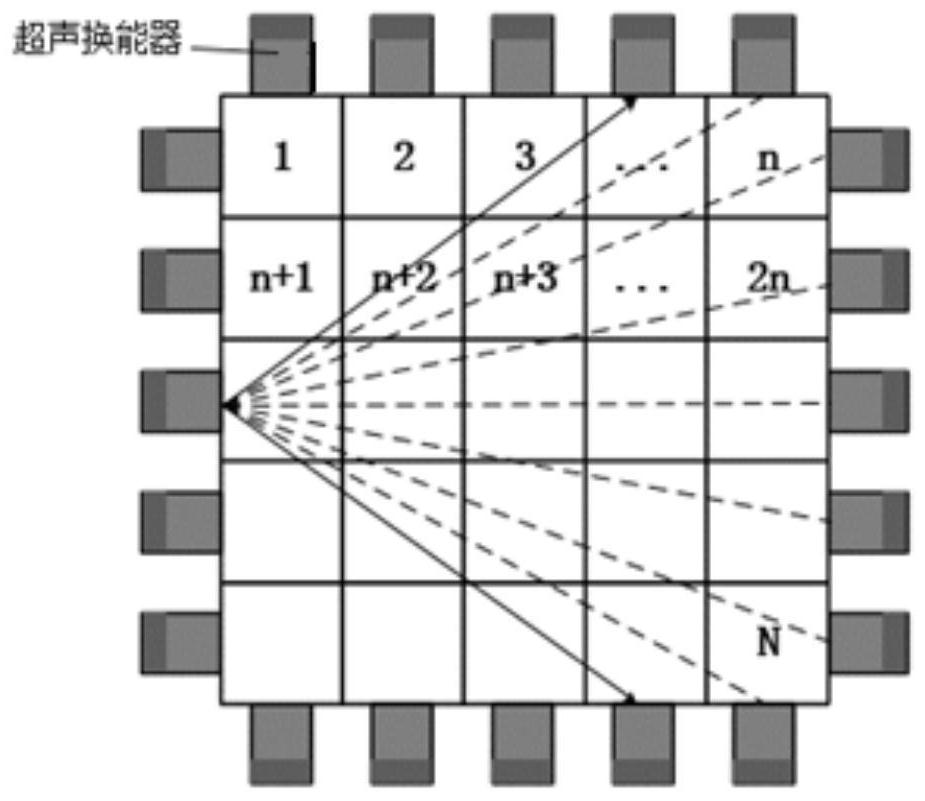

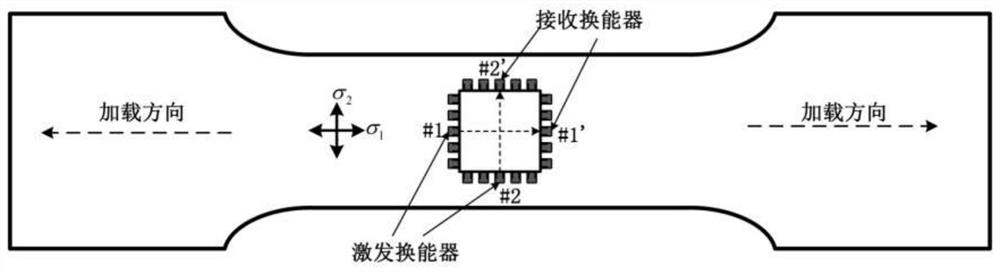

The invention provides a stress field measurement method based on ultrasonic tomography, which belongs to the technical field of ultrasonic nondestructive testing. The method comprises the steps of carrying out a calibration test; determining a projection coefficient matrix; zero-stress reference acquisition: sequentially exciting each ultrasonic transducer in an ultrasonic transducer array to obtain a zero-waveform data set; measurement data acquisition: sequentially exciting each ultrasonic transducer in the ultrasonic transducer array according to the excitation sequence of zero-stress reference acquisition to obtain a test waveform data set; carrying out delay calculation, and using a cross-correlation algorithm for solving to obtain a corresponding stress delay vector; solving a stress field equation, and solving the stress field equation by using a tomography algorithm to obtain a stress vector; and drawing a stress field image according to the stress vector. On the basis of theultrasonic tomography algorithm, a probe scanning matrix is constructed, so that the shallow surface stress field distribution of a workpiece can be obtained by single measurement without moving the probe, the requirement on an operator is reduced, and the measurement efficiency is improved.

Description

technical field [0001] The invention relates to a stress field measurement method based on ultrasonic tomography, belonging to the technical field of ultrasonic nondestructive testing. Background technique [0002] The material will inevitably produce plastic strain during the mechanical manufacturing process, resulting in residual stress. At the same time, during the service process of the workpiece, the interior of the workpiece is affected by aging or external loads, and the stress will change. Measuring the surface stress of the workpiece can not only provide data support for the safety evaluation of the structural service, but also improve the production process and component processing methods on this basis to further extend the service life of the workpiece and reduce production and operation costs. [0003] There are many kinds of stress detection technologies in objects, which can be subdivided into three categories according to whether the detected object is damage...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01L5/00

CPCG01L5/0047

Inventor 陈兵苟国庆高唯于金朋朱忠尹张曦陈佳胡彧孜邱菲菲

Owner 四川中创辰安检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com