Device and method for detecting slurry filling fullness in mechanical sleeve grouting construction stage

A technology of sleeve grouting and construction stage, which is applied in measurement devices, material inspection products, analysis materials, etc., can solve problems such as irreparable grouting quality defects, achieve the effect of easy mass production and promotion, and ensure quality controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

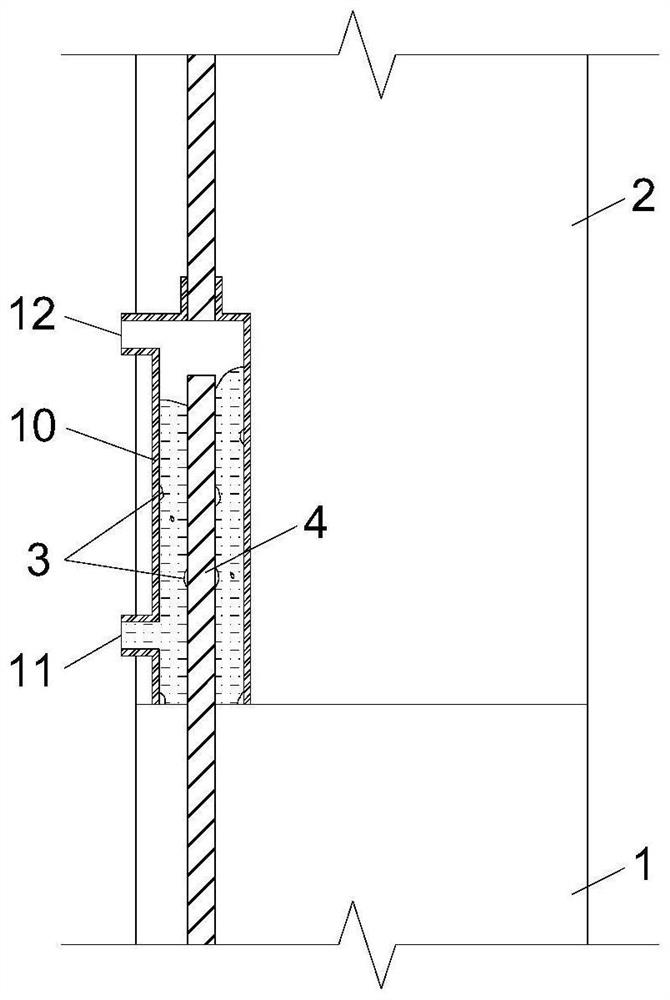

[0042] combine Figure 2 to Figure 5 The mechanical sleeve grouting construction stage slurry filling fullness detection device of the present invention includes:

[0043] The back pressure device 20 is arranged in the inner cavity of the sleeve 10 and coincides with the axis of the sleeve 10;

[0044] The data acquisition and analysis module 40 is connected with the back pressure device 20 for signal;

[0045] Wherein, the counter pressure device 20 comprises a pressure measuring plate 22, a counter pressure plate 21, a plurality of suspension rods 24, a plurality of sliding springs 25 and a plurality of pressure sensors 27, and the outer diameter of the pressure measuring plate 22 and the counter pressure plate 21 is the same as that of the sleeve 10. The inner diameter is compatible, the pressure measuring plate 22 and the counter pressure plate 21 are arranged at intervals above and below, a plurality of suspension rods 24 are evenly distributed between the pressure measu...

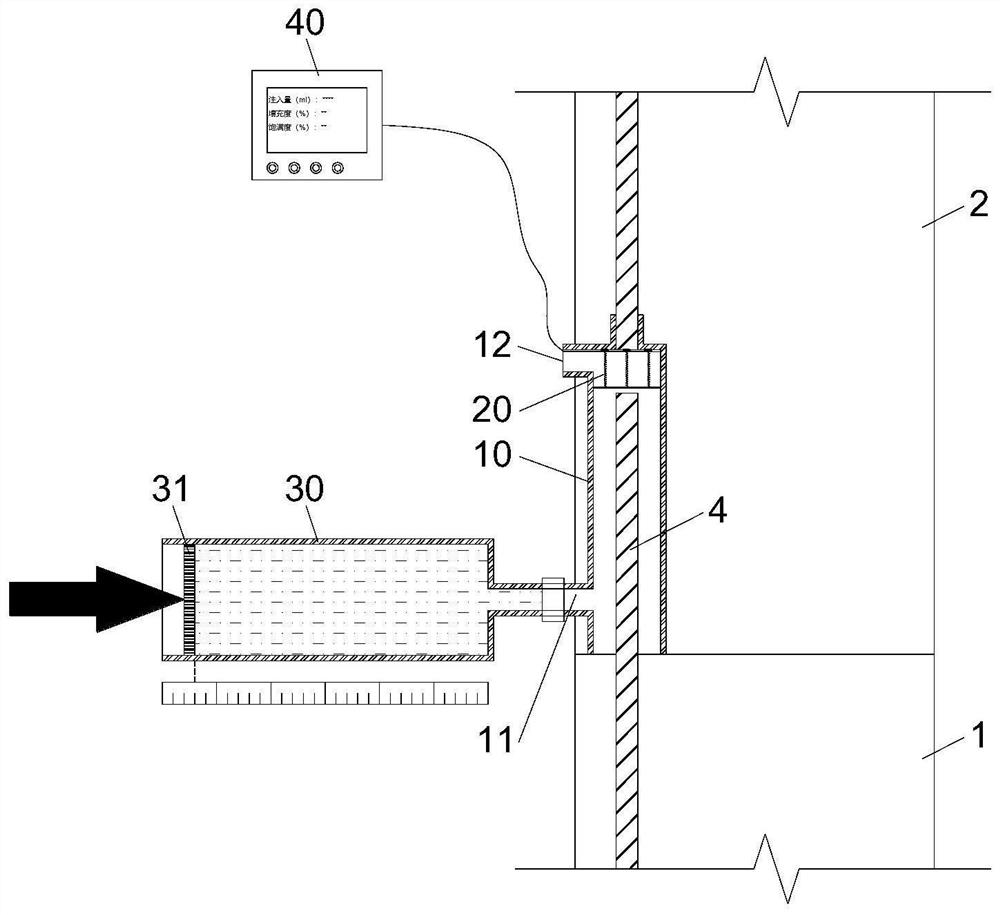

Embodiment 2

[0051] Different from Embodiment 1, the mechanical sleeve grouting construction stage slurry filling fullness detection device of the present invention also includes a pouring cylinder 30, which is connected to the grouting hole 11 of the sleeve 10, and the outer wall of the pouring cylinder 30 With a scale, it is convenient for construction personnel to intuitively and quickly calculate the volume of grout.

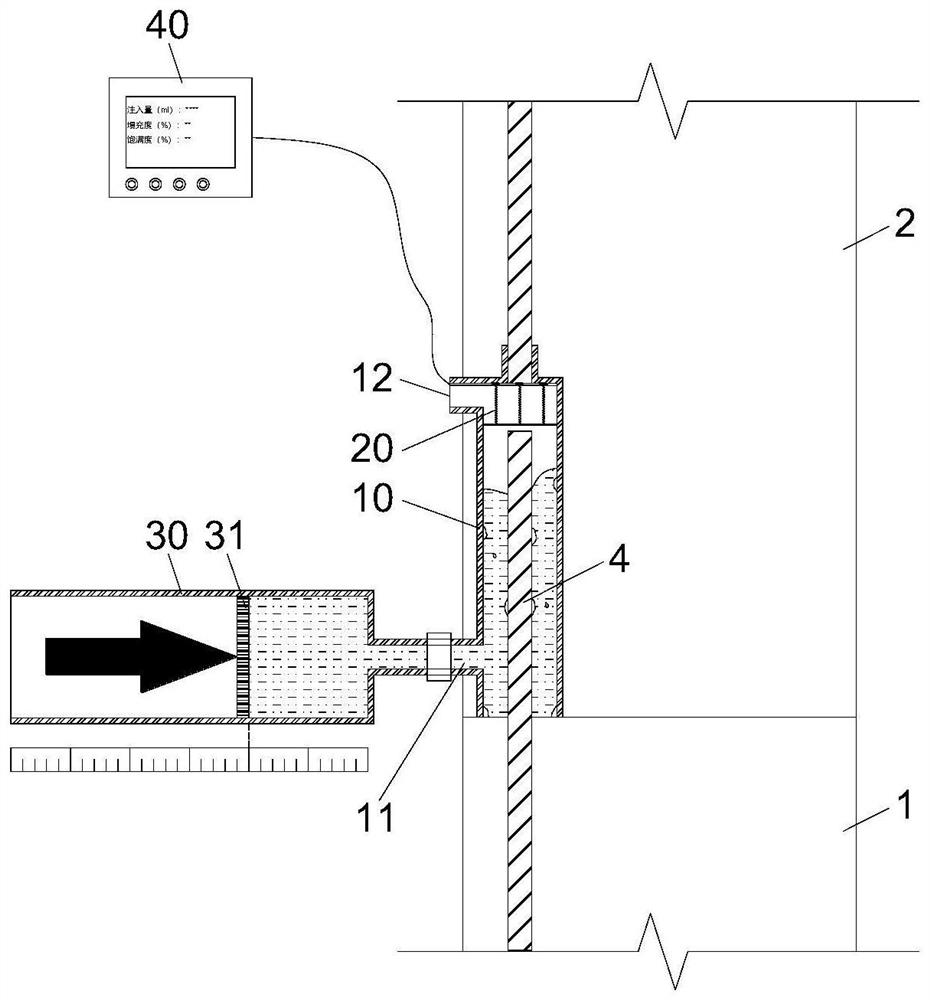

Embodiment 3

[0053] combine Figure 2 to Figure 5 The method for detecting the fullness of slurry filling in the mechanical sleeve grouting construction stage of the present invention is described, and the specific steps are as follows:

[0054] S1: Pre-measure the actual inner cavity volume V after the sleeve 10 is inserted into the embedded steel bar 4 rc , open the piston 31 of the perfusion cylinder 30, inject an appropriate amount of slurry into the inner cavity of the perfusion cylinder 30, ensure the 100% compactness of the slurry in the perfusion cylinder 30 by manual vibration, etc., close the piston 31 of the perfusion cylinder 30, and eliminate the perfusion The gas in the cylinder 30 is read through the scale on the side of the cylinder 30 to read the volume V of the slurry in the cylinder at this time g0 , and ensure the slurry volume V in the cylinder g0 Slightly higher than the actual inner cavity volume V after the sleeve 10 is inserted into the embedded steel bar 4 rc ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com