Curved surface electrode plasma generating device for solving non-uniform discharge, and working method

A plasma and generating device technology, applied in the field of plasma generating devices, can solve the problems of partial discharge, uneven discharge, etc., and achieve the effects of uniform discharge, wide practicability in size, and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

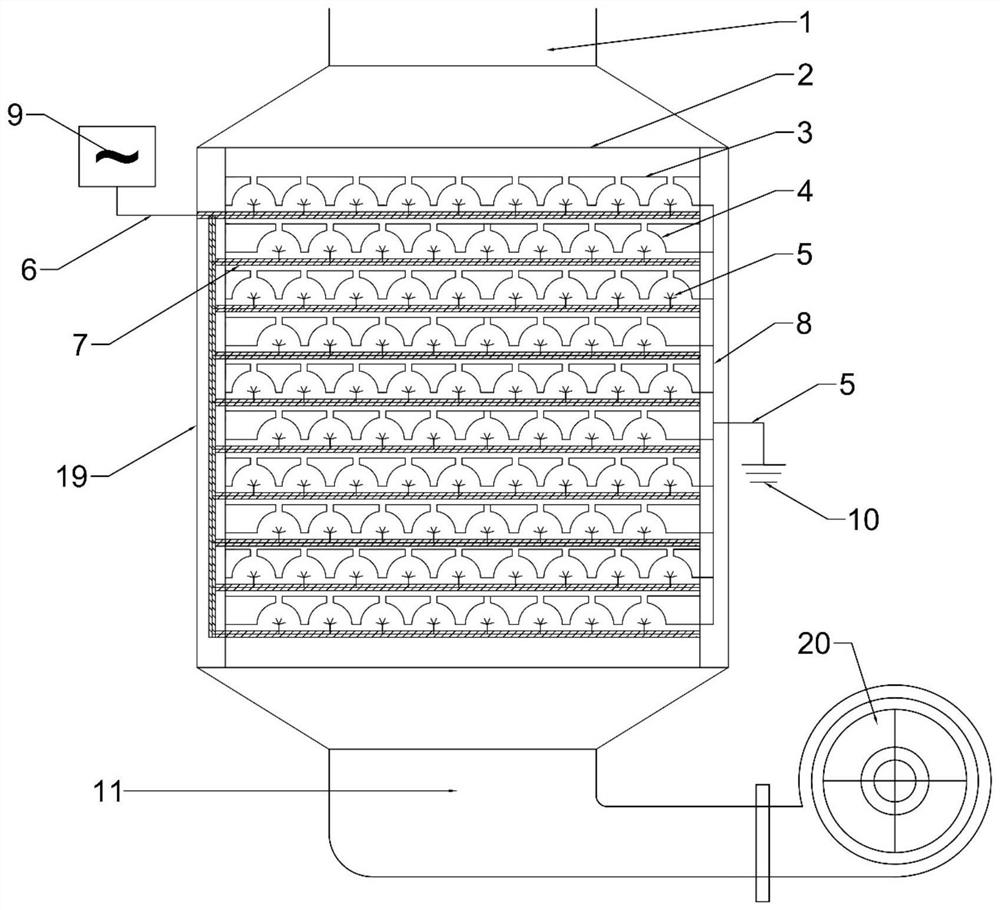

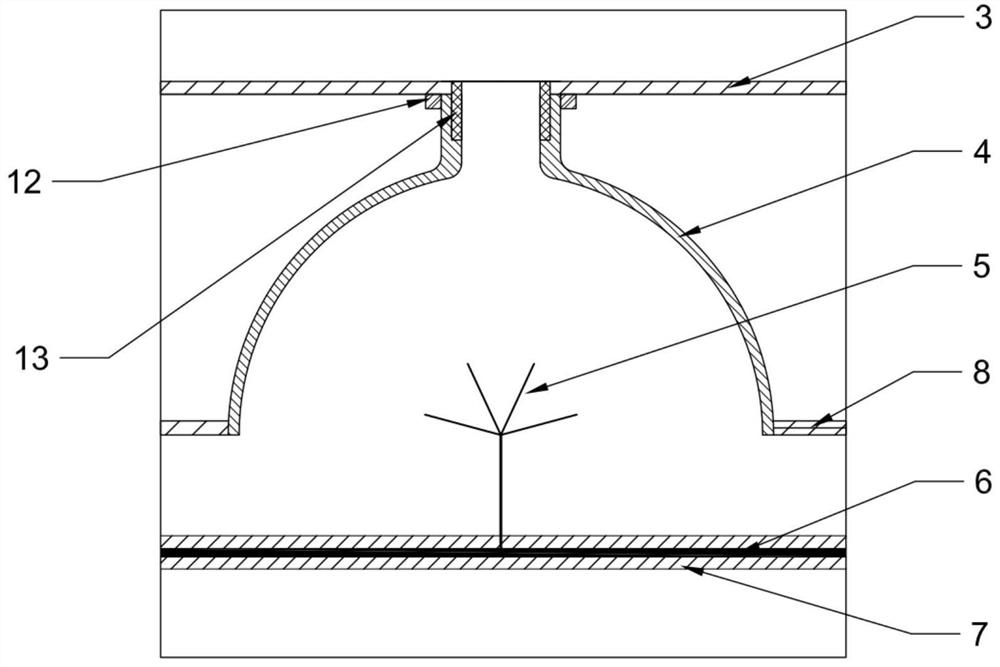

[0034] combined with figure 1 with figure 2 As shown, a pollutant degradation device for solving uneven discharge, including an air intake pipe 1, a rectifying plate 2, a separator 3, a curved electrode 4, a needle electrode 5, a power input line 6, an insulating layer 7, and a grounding lead 8 , high-voltage power supply 9, grounding device 10, air outlet pipe 11, fixed ring 12, insulating pipe 13, housing 19 and induced draft fan 20; air inlet pipe 1, housing 19 are connected to air outlet pipe 11 in sequence, and air inlet pipe 1 and A rectifying plate 2 is provided at the joint of the housing 19 and at the joint of the housing 19 and the air outlet pipe 11 .

[0035] The needle-shaped electrode 5 and the curved surface electrode 4 form a discharge processing unit, and a plurality of discharge processing units are arranged in the housing 19, and wire collecting devices are arranged on both sides; The ground wire 8 is grounded, and the outer side of the power input wire 6...

Embodiment example 2

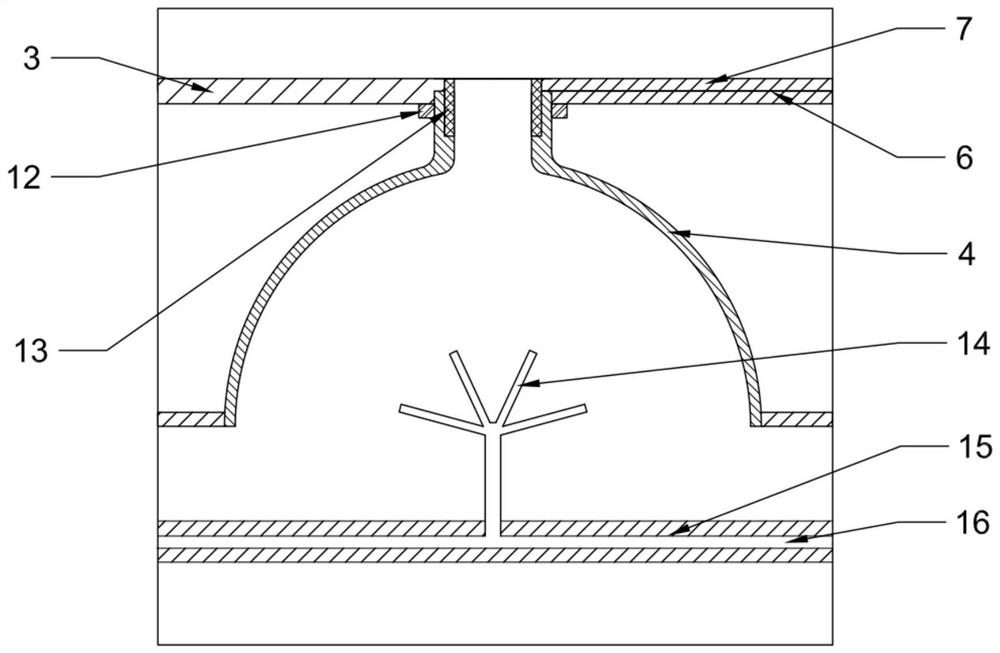

[0044] combined with image 3 with Figure 4 As shown, a pollutant degradation device for solving uneven discharge uses a nozzle electrode 14, the nozzle electrode 14 is used as a ground electrode, connected to the ground device, and the curved surface electrode 4 is used as a high-voltage electrode, connected to a high-voltage power supply 9. The electrode gas 16 is provided by external equipment, and is passed into the nozzle electrode 14 through the gas outer pipe 18, the insulating gas pipe 17 and the gas pipeline 15, and the gas pipeline 15 is used as the grounding wire of the nozzle electrode 14 at the same time, and the insulating gas pipe 17 connects the gas outer pipe 18 and the The gas pipeline 15 is isolated to prevent current leakage. The gas pipeline and the ground wire 15 are covered with an insulating layer. The rest is the same as implementation case 1. It should be noted that the nozzle electrode 14 is a tree structure composed of several communicating holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com