Cleaning detection method for vacuum glass element

A detection method and technology of vacuum glass, applied in cleaning methods and utensils, electrical components, chemical instruments and methods, etc., can solve problems such as poor etching uniformity, achieve uniform and stable surface, solve uneven discharge, and uniform effect of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

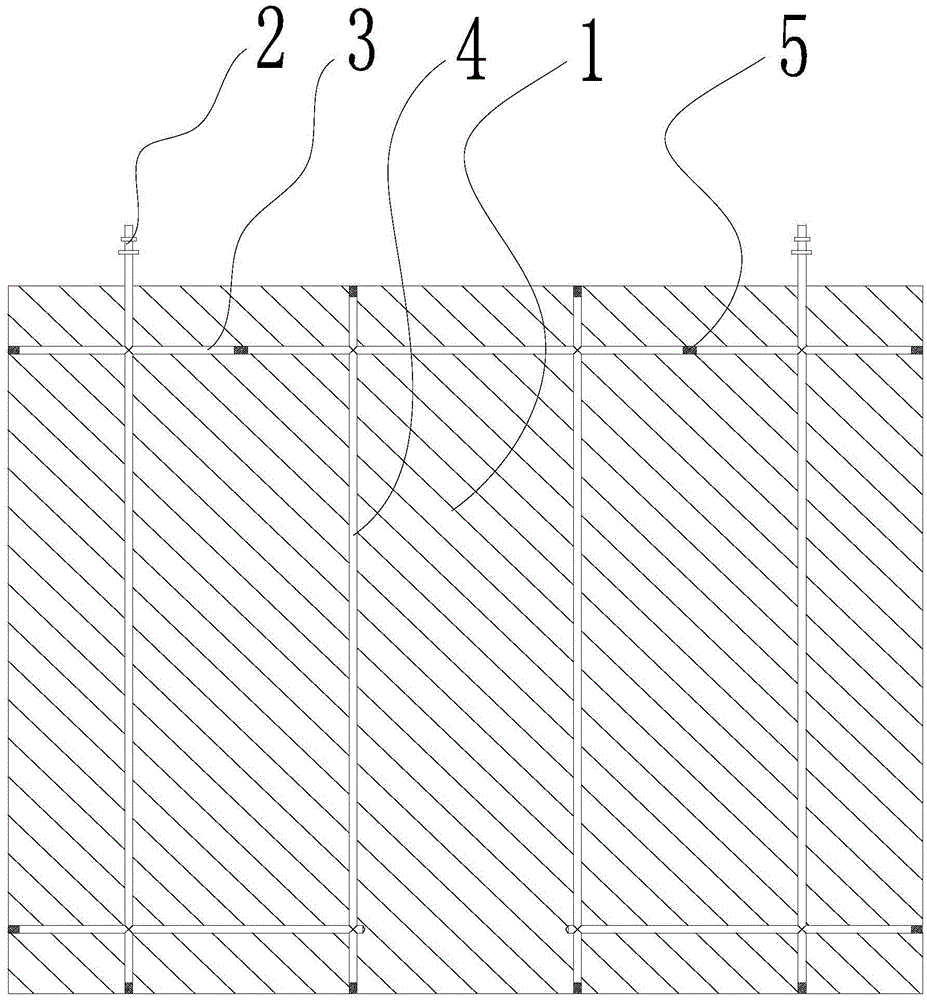

[0019] Such as figure 1 As shown, a cleaning and testing method for vacuum glass components of the present invention includes an electrode plate body 1, the electrode plate body 1 is 180 cm long, 150 cm wide, and 2 cm thick, and two parallel electrodes are provided inside the electrode plate body 1. The transverse duct 3, four longitudinal ducts 4 perpendicular to the transverse duct 3, the four longitudinal ducts 4 and the two transverse ducts 3 communicate with each other, and the longitudinal duct 4 and the transverse duct 3 form 12 openings on the side of the electrode plate body 1. 10 of the openings are sealed with plugs 5, and then the horizontal pipe 3 and / or the longitudinal pipe 4 are divided by the plug 5 inside the electrode plate body 1 to form a unidirectional circulation channel as a circulation pipe. According to actual production needs, the form and flow direction of the circulation pipeline can be changed and combined, and the number and spacing of the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com