Atmospheric pressure high-frequency cold plasma processing device

A technology of cold plasma and treatment device, applied in the field of plasma treatment device, can solve problems such as surface modification, and achieve the effect of solving uneven discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

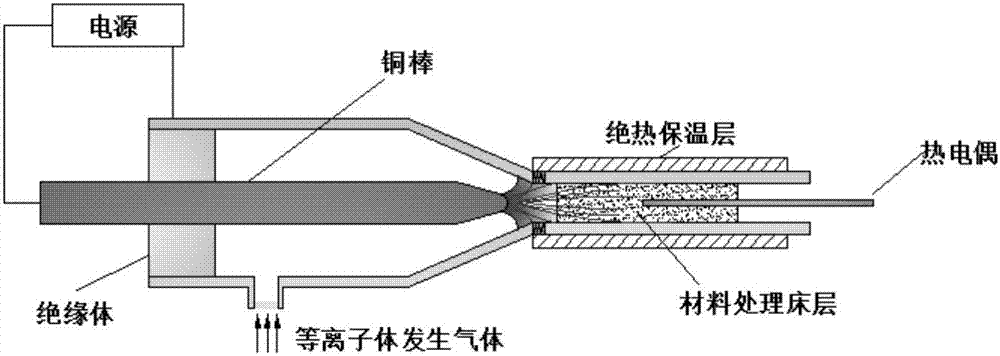

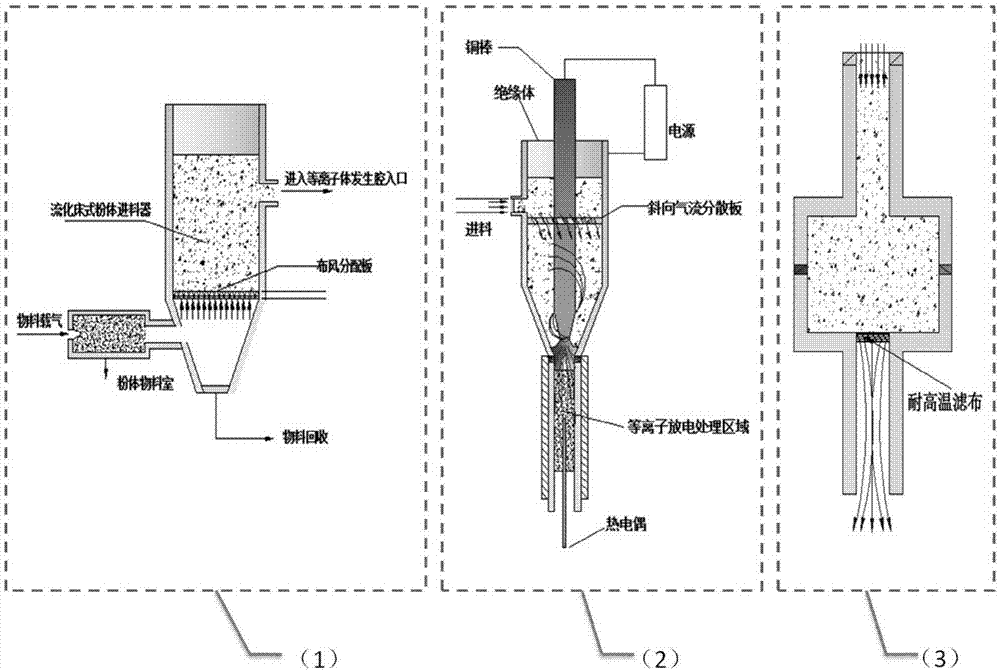

[0026] Such as figure 2 As shown, it is a schematic structural diagram of the atmospheric pressure high frequency cold plasma treatment device provided by the present invention; it includes a fluidized bed feed unit (1), a plasma generation unit (2) and a middle expansion type material collection unit (3).

[0027] Such as figure 2 As shown in (1), the fluidized bed feeding unit includes a powder material chamber, an air distribution plate and a fluidized bed powder feeder, and the material carrier gas passes through the powder at a flow rate of 20-40L / h. The material chamber, and then pass through the air distribution plate (the air distribution plate is a general accessory of the fluidized bed, and its aperture can be selected according to the demand, specifically 1-2 mm.) to evenly disperse the fine particle powder in the carrier gas, and then Enter the plasma generation unit through the outlet of the fluidized bed powder feeder for plasmaization; wherein, the fluidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com