A pre-stabilized recoil filter

A pre-stabilization and filter technology, which is applied to fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of filter explosion, tube collapse, damage to pipeline connections, rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

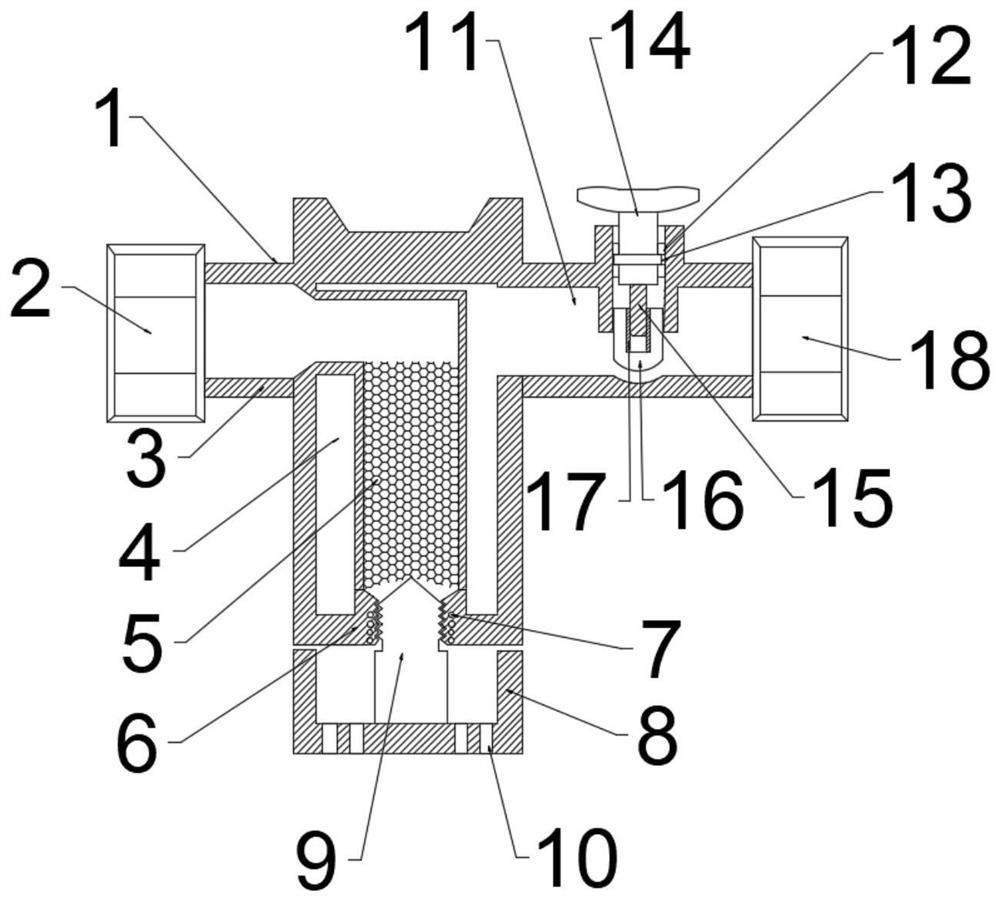

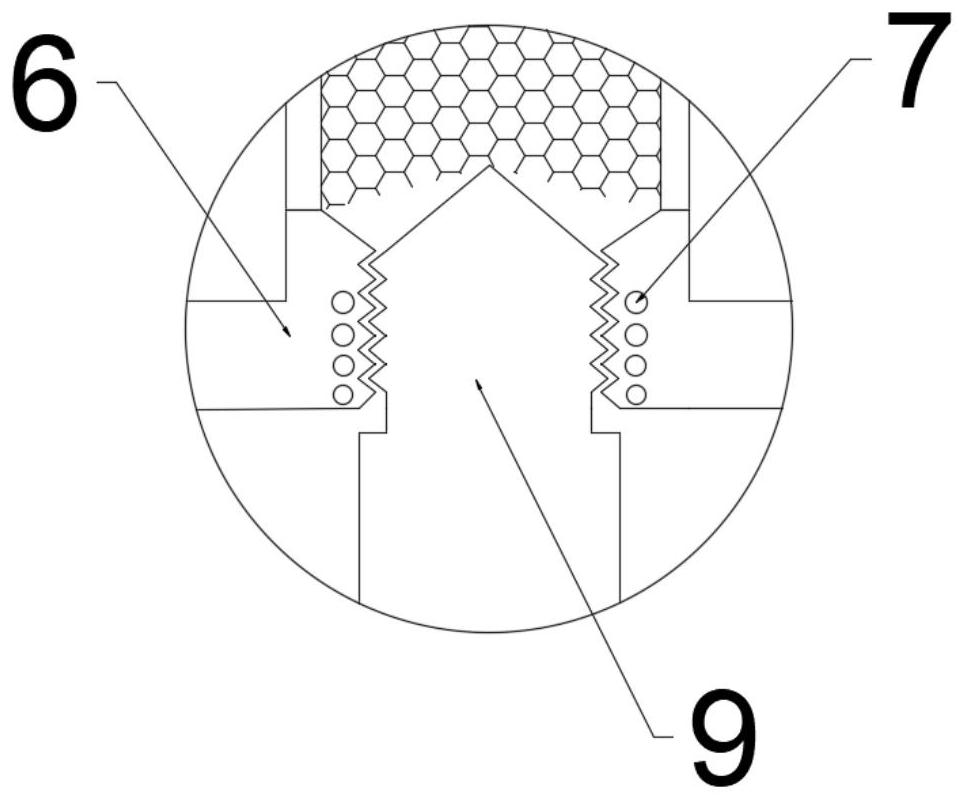

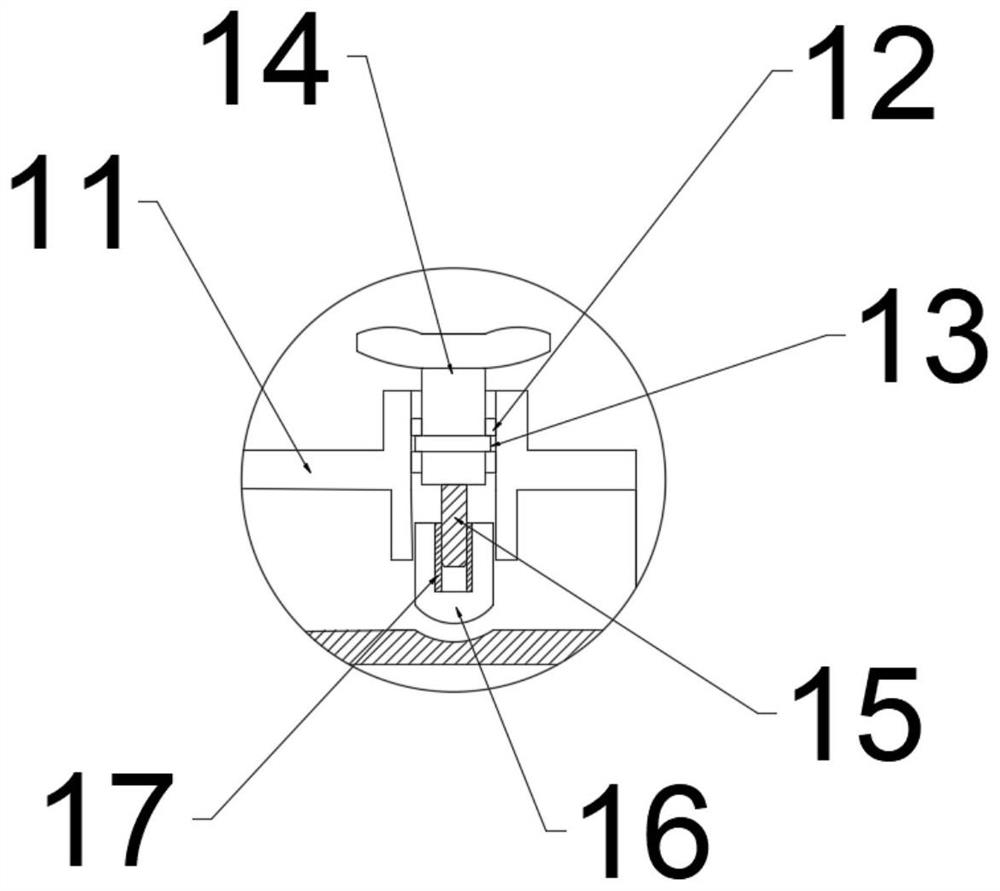

[0025] See Figure 1 ~ 3 , A pre-regulatory renapper filter includes a filter chamber 4, a filter film 5, a threaded port 6, a pressure relief hole 7 sealing column 9, and a shut-off valve 16, wherein the filter film 5 for water purification is mounted in the shell The middle portion of the body 1, the outer side of the filter membrane 5 is provided with a filter cavity 4, and the filter film 5 is provided with a threaded port 6, and the thread of the threaded port 6 is provided with a pressure relief hole 7, and the threaded port 6 is provided with a sealing filter. 5 The sealing column 9, and the right side of the housing 1 is provided with a shut-off valve 16 for regulating.

[0026] The housing 1 is provided on the left side of the water supply interface 2, and the water supply pipe 3 is attached to the right side of the water supply interface 2, and the water supply interface 2 is connected to the housing 1, and the feed pipe 3 is connected to the filter film 5 The base 8 is p...

Embodiment 2

[0030] See Figure 4 , A pre-stress-stamping filter is the same as in Example 1, and the filter film 5 is improved, and a card slot 19 is attached to the end of the water pipe 3, and the filter film 5 is mounted on the filter shell 20. In the upper, the filter case 20 is provided with a threaded end 21 between the casing 1, and the filter case 20 is fixed to the housing 1 by the threaded end 21.

[0031] The working principle of the present invention is that when the filter film 5 needs to be replaced, the base 8 is first removed from below, and then the filter case 20 is screwed from the housing 1, and the filter film 5 is replaced. After replacement is completed. The filter case 20 is inserted into the housing, so that the top of the filter case 20 is embedded in the card tank 19, then tighten the threaded end 21, and then tighten the base 8 up, and the replacement of the filter film 5 is completed.

[0032] An advantage of this embodiment is that by removable filter case 20, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com