Suspension device for aluminum alloy profile spraying and spraying method

A technology of aluminum alloy profiles and suspension devices, applied in the direction of spraying devices, can solve problems such as poor spraying effect and increase cost, and achieve the effects of increasing friction, increasing contact area, and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

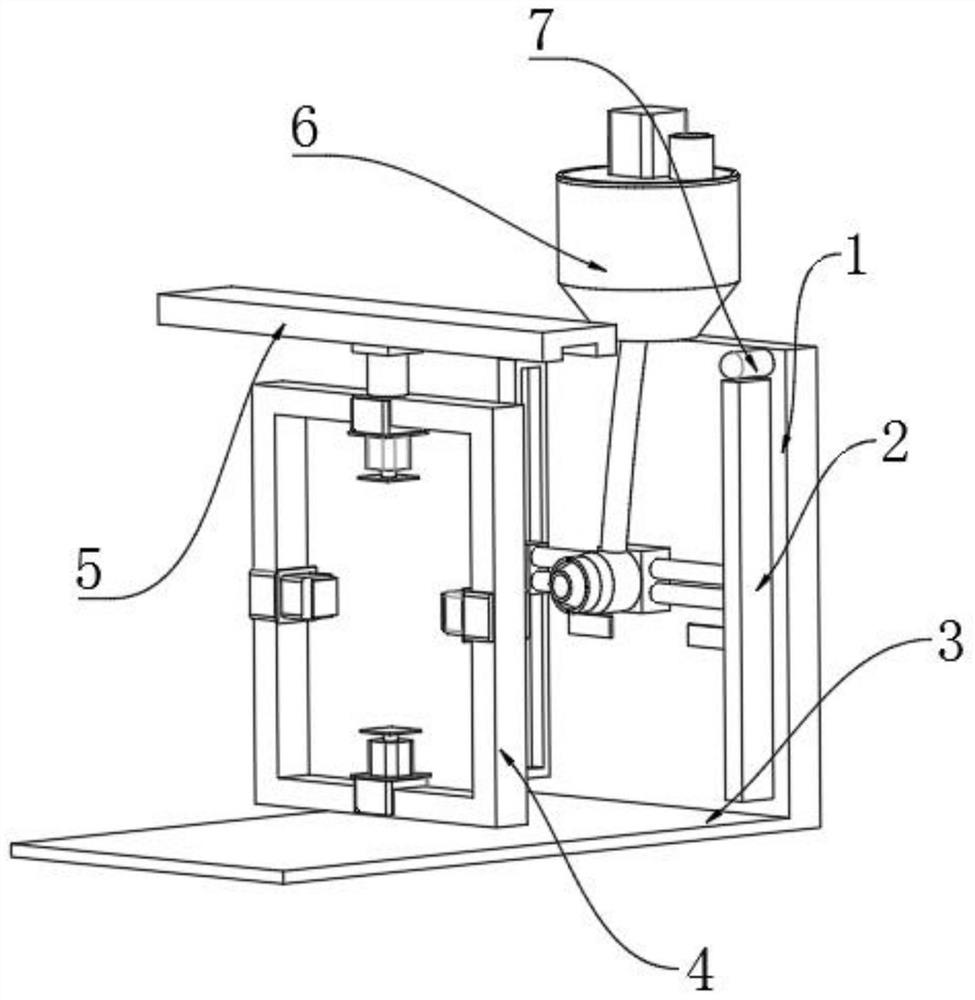

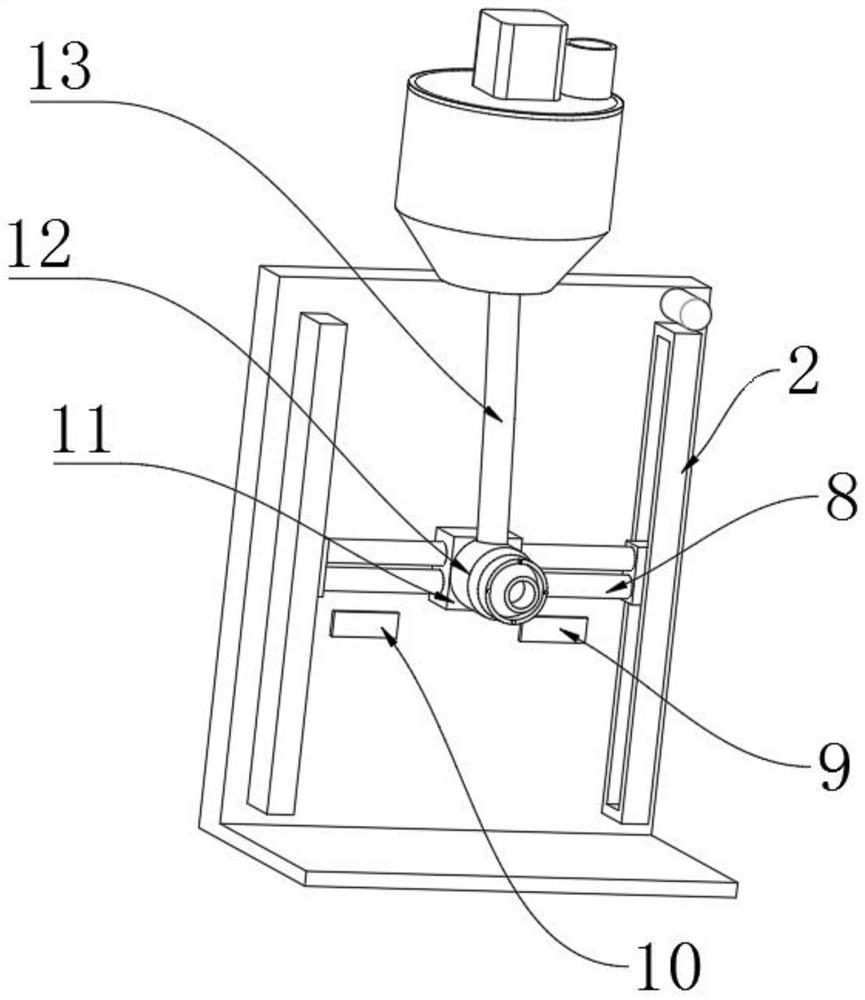

[0038] A suspension device for spraying aluminum alloy profiles, in order to speed up the purification of water, such as figure 2 , Figure 4 , Figure 7As shown, it includes a support plate 1; the outer wall of the bottom end of the support plate 1 is fixedly connected with a bottom plate 3 by screws; a transmission electric guide rail 5 is arranged above the bottom plate 3; an electric slider 14 is slidingly connected to the inner wall of one side of the transmission electric guide rail 5; The outer wall on one side of the slider 14 is fixedly connected with a fixed frame 4 by screws; the upper and lower inner walls of the fixed frame 4 are connected with a longitudinal electric push rod 20 by bolts; the outer wall on one side of the output shaft of the vertical electric push rod 20 is fixed and connected with a push plate 16. The outer wall on one side of the push plate 16 is connected with a longitudinal servo motor 17 by bolts; There is a horizontal servo motor 19; the...

Embodiment 2

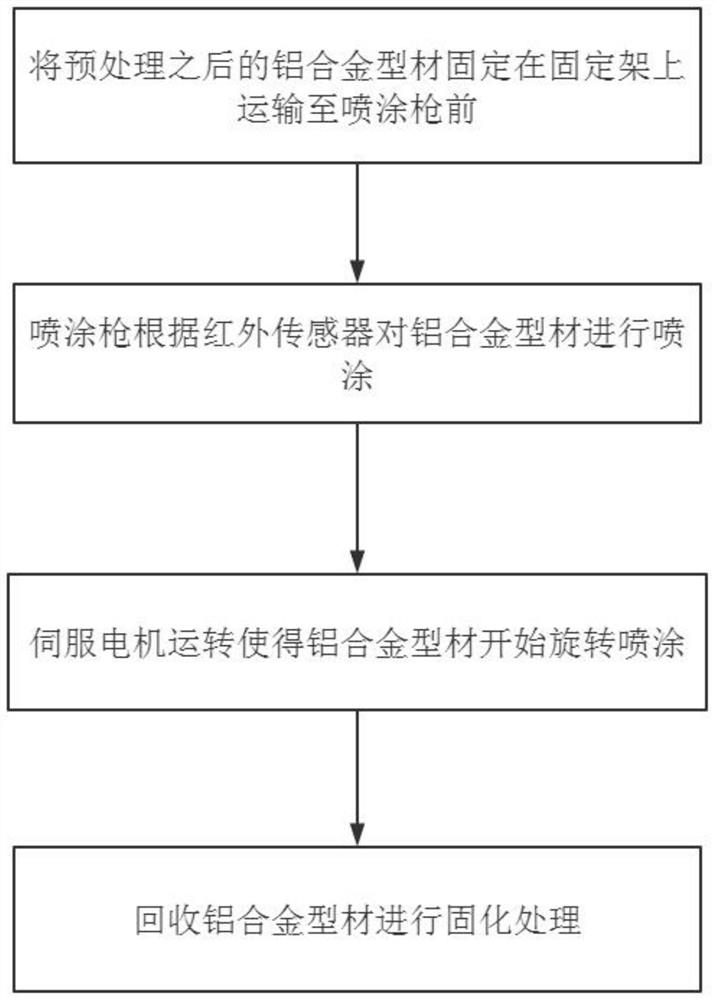

[0045] A spraying method of the suspension device for aluminum alloy profile spraying according to Embodiment 1, such as figure 1 shown, including the following steps:

[0046] S1: Fix the pretreated aluminum alloy profile on the first electric guide rail 2 and transport it to the spray gun 12;

[0047] S2: the spraying gun 12 sprays the aluminum alloy profile according to the infrared sensor 23;

[0048] S3: The rotation of the servo motor makes the aluminum alloy profile start to rotate and spray;

[0049] S4: Recycling aluminum alloy profiles for curing.

[0050] When this embodiment is in use, turn on the power supply of various electrical equipment, first push the fixing plates 18 on the upper and lower sides through the longitudinal electric push rod 20 to fix the aluminum alloy profile, and now the horizontal electric push rod 15 is in a contracted state. After the block 14 transports the aluminum alloy profiles to the designated location, the aluminum alloy profiles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com