Automatic packaging equipment for wheel storage and transportation

An automatic packaging and wheel technology, which is applied in the direction of rotating and wrapping items, can solve the problem of low efficiency in the process of wrapping tapes, and achieve the effect of improving the automation of the process, avoiding turning over tires, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

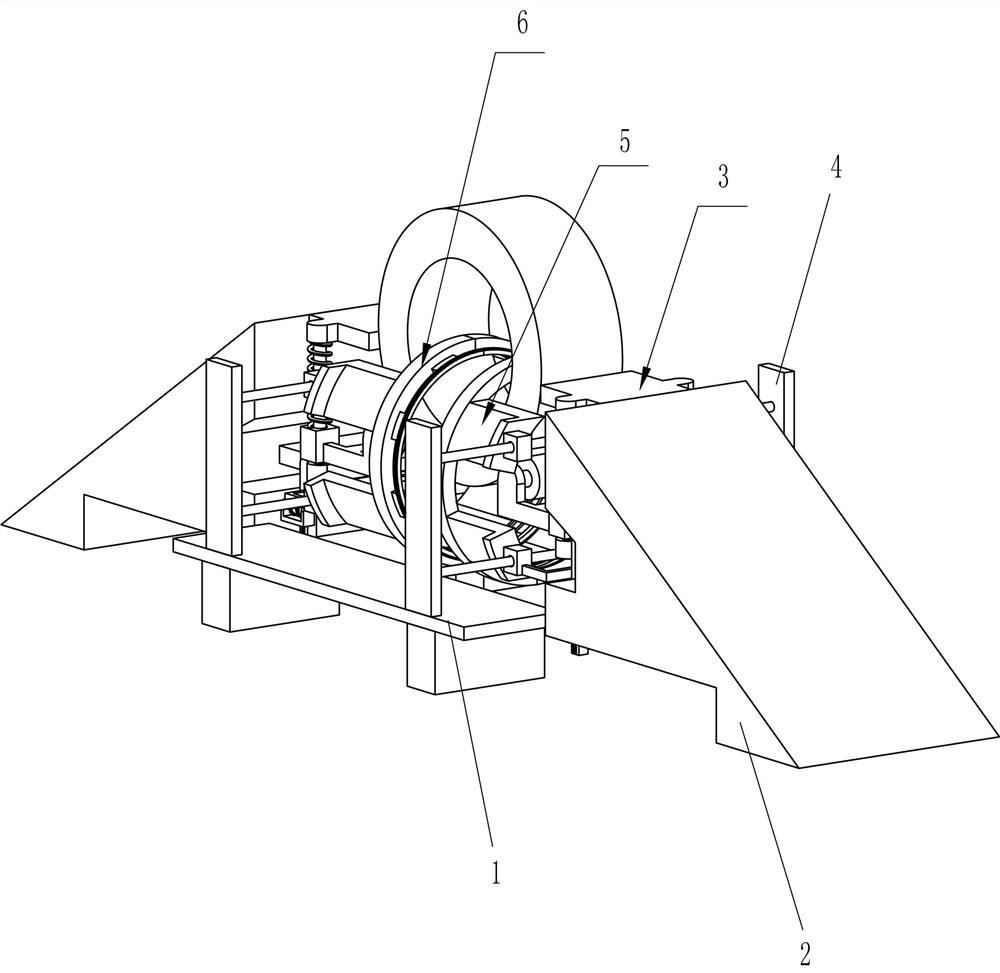

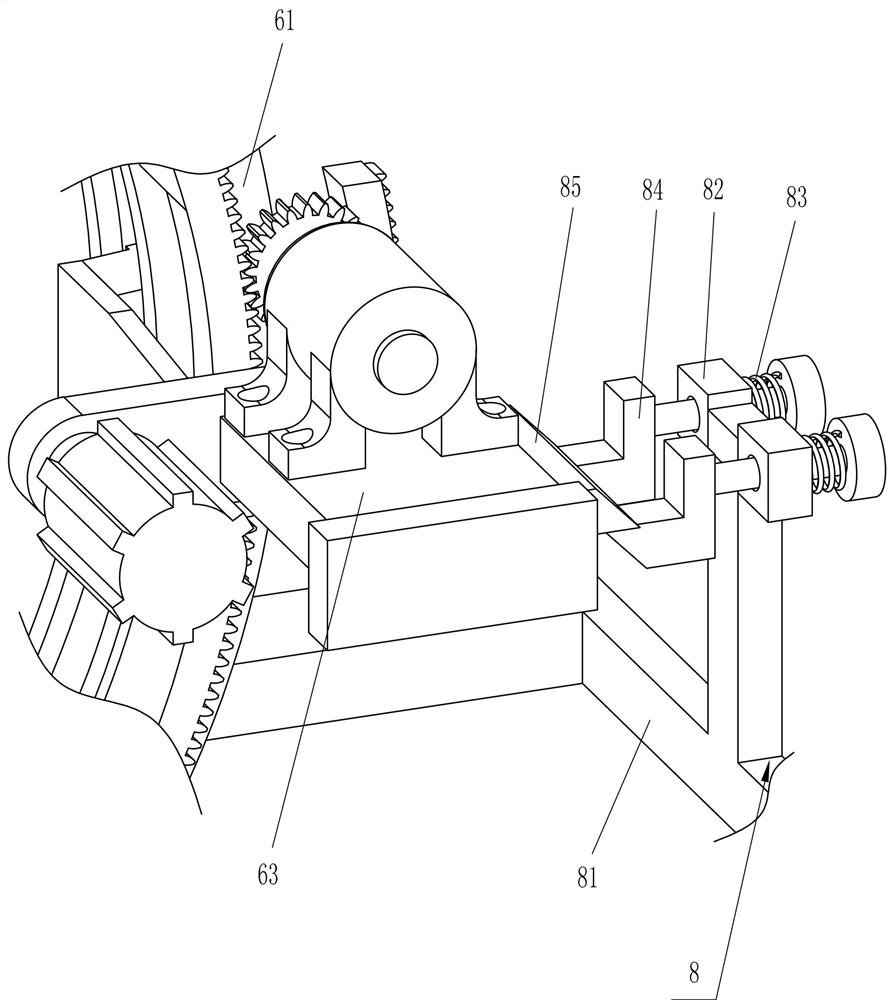

[0031] An automatic packaging equipment for wheel storage and transportation, such as Figure 1-4 As shown, it includes a bottom frame 1, a slope frame 2, a placement device 3, a support rod 4, a transmission device 5, and a winding device 6, specifically:

[0032] The left and right sides of the underframe 1 are connected with a ramp frame 2, the inside of the ramp frame 2 is provided with a placement device 3, and the front and rear sides of the underframe 1 are connected with two support rods 4, and the opposite support rods 4 are provided with There are transmission devices 5, and the transmission devices 5 are all connected to the placing device 3, and a winding device 6 is arranged between the transmission devices 5.

[0033] When the above-mentioned embodiment is in operation, when it is necessary to wrap a new tire with adhesive tape so that its internal space will not be subject to the entry of dust in the transportation and storage process, the tire can be placed bet...

Embodiment 2

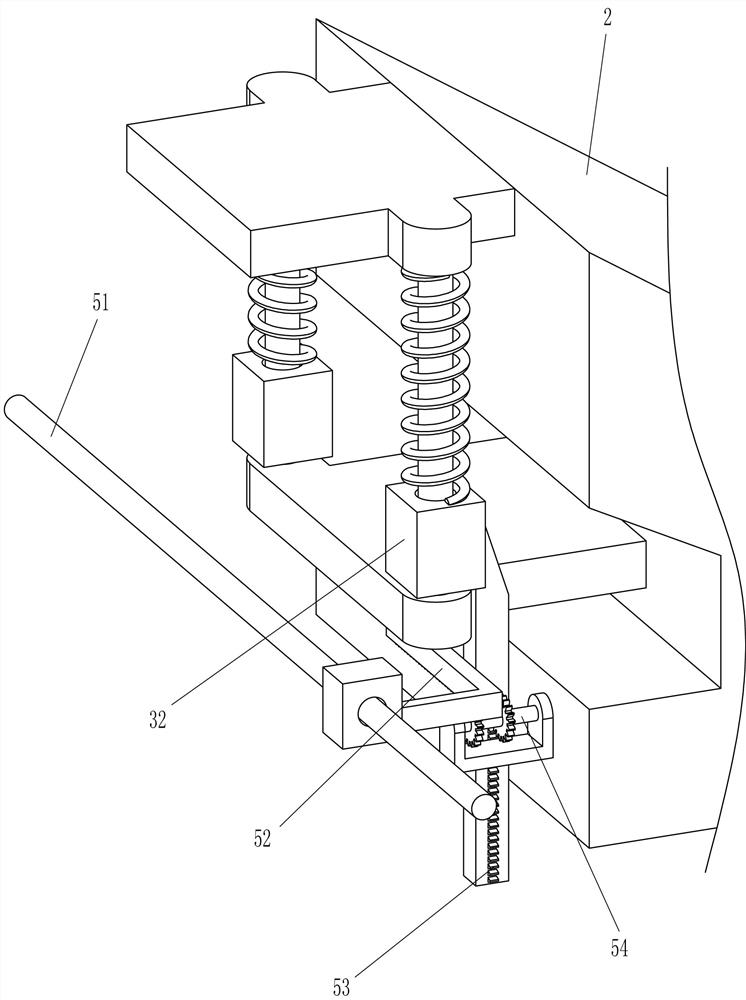

[0035] On the basis of Example 1, such as Figure 1-12 As shown, the placing device 3 includes a bracket 31, a first moving pair 32, a first elastic member 33, a connecting frame 34 and a supporting wheel set 35, specifically:

[0036]The inside of the ramp frame 2 is connected with a bracket 31, the bracket 31 is connected with a first mobile pair 32, the moving part of the first mobile pair 32 is connected with the transmission device 5, and the first mobile pair 32 is connected with a first elastic 33, the inner side of the moving part of the first moving pair 32 is connected with a connecting frame 34, and the inner side of the connecting frame 34 is connected with a supporting wheel set 35 in a rotational manner.

[0037] When the above-mentioned embodiment is in operation, the tire can be placed between the supporting wheel set 35, the supporting wheel set 35 will support the tire, and the tire will press the supporting wheel set 35 downward, thereby driving the moving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com