A kind of Bnt-based energy storage ceramic material and its preparation method and application

A ceramic material and energy storage technology, which is applied to fixed capacitor parts, fixed capacitors, fixed capacitor dielectrics, etc., can solve the problems that cannot be reduced at the same time, and achieve the effects of avoiding sample defects, reducing pores, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

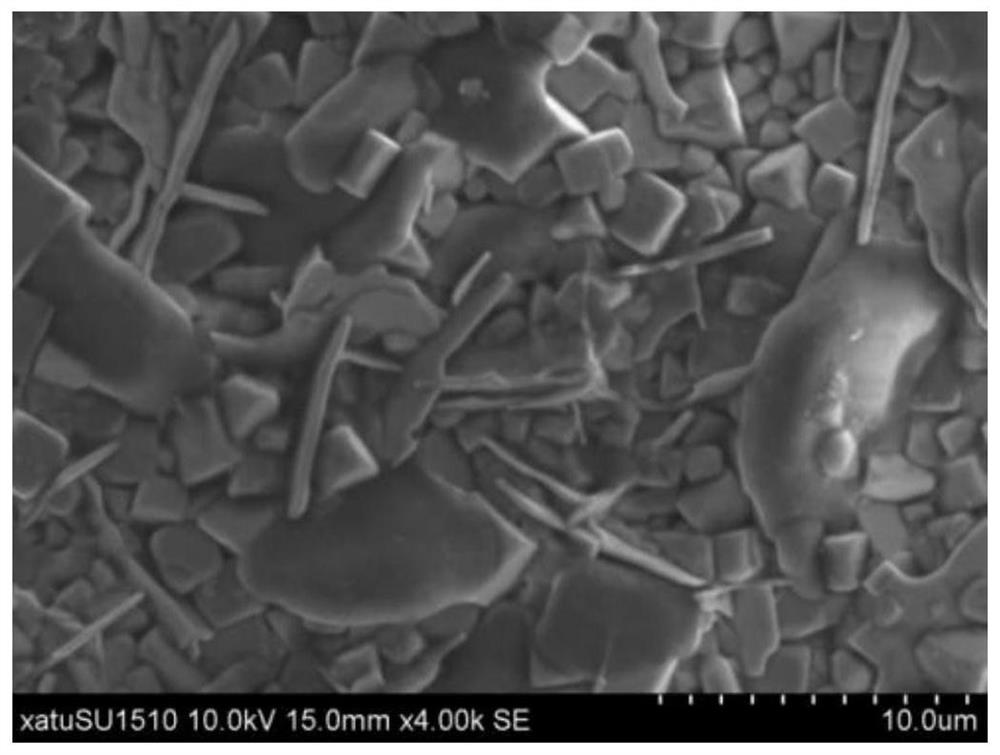

[0026] This example is a BNT-based energy storage ceramic material whose chemical formula is (Bi 0.5 Na 0.5 Ti 0.95 Al 0.025 O 3 ) 1-x (SrSc 0.5 Nb 0.5 O 3 ) x , where x=0, where x is the number of moles.

[0027] The analytically pure raw material Bi 2 O 3 , Na 2 CO 3 , TiO 2 , Al 2 O 3 , Nb 2 O 5 , SrCO 3 , Sc 2 O 3 Incubate in an oven at 120°C for 12 hours.

[0028] Weigh the raw material obtained in step 1 according to the stoichiometric ratio and pour it into a ball mill jar.

[0029] The raw materials obtained in step 2 were put into a planetary ball mill according to the mass ratio of raw materials: zirconium balls: absolute ethanol as 1:1:2, and the ball milling time was 12h.

[0030] Pour the product of step 3 into a petri dish, put it into an oven at 60° C. to dry, and then use a 60-mesh sieve for sieving to separate the zirconium spheres from the powder.

[0031]The powder obtained in step 4 was raised to 850 °C at 3 °C / min, and kept in a high...

Embodiment 2

[0040] This example is a BNT-based energy storage ceramic material whose chemical formula is (Bi 0.5 Na 0.5 Ti 0.95 Al 0.025 O 3 ) 1-x (SrSc 0.5 Nb 0.5 O 3 ) x , where x=0.05, where x is the number of moles.

[0041] The analytically pure raw material Bi 2 O 3 , Na 2 CO 3 , TiO 2 , Al 2 O 3 , Nb 2 O 5 , SrCO 3 , Sc 2 O 3 Incubate in an oven at 120°C for 12 hours.

[0042] Weigh the raw material obtained in step 1 according to the stoichiometric ratio and pour it into a ball mill jar.

[0043] The raw materials obtained in step 2 were put into a planetary ball mill according to the mass ratio of raw materials: zirconium balls: anhydrous ethanol to 1:1:2 for a ball milling, and the ball milling time was 12h.

[0044] Pour the product of step 3 into a petri dish, put it into an oven at 60° C. to dry, and then sieve it with a 60-mesh sieve to separate the zirconium balls from the powder.

[0045] The powder obtained in step 4 was raised to 850 °C at 3 °C / min...

Embodiment 3

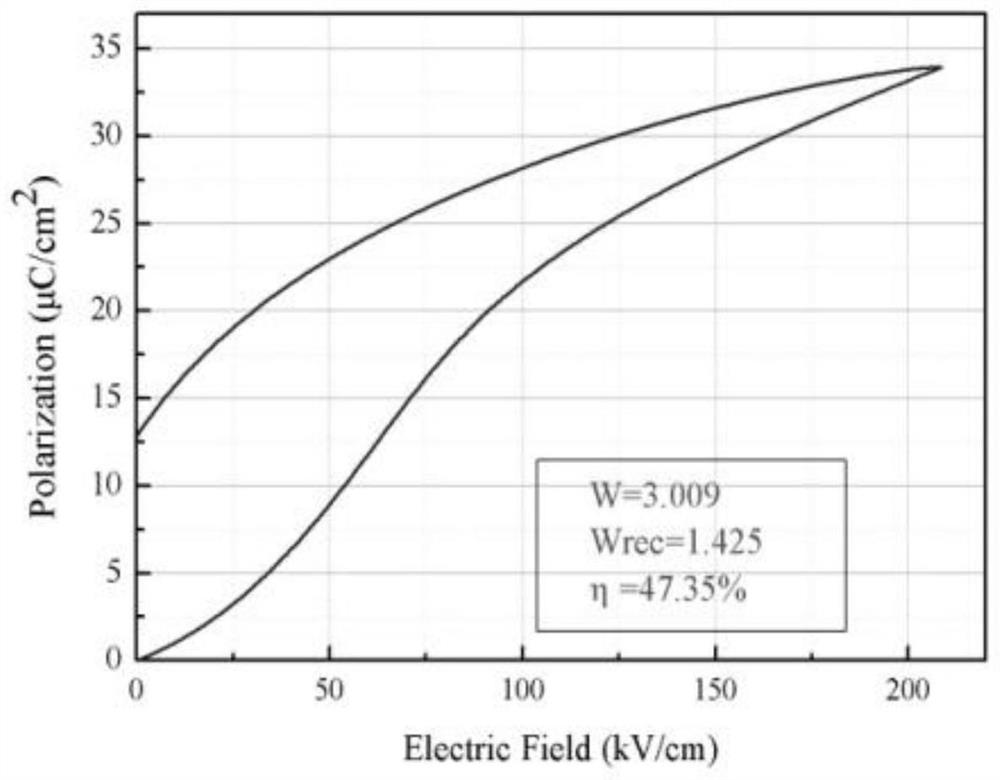

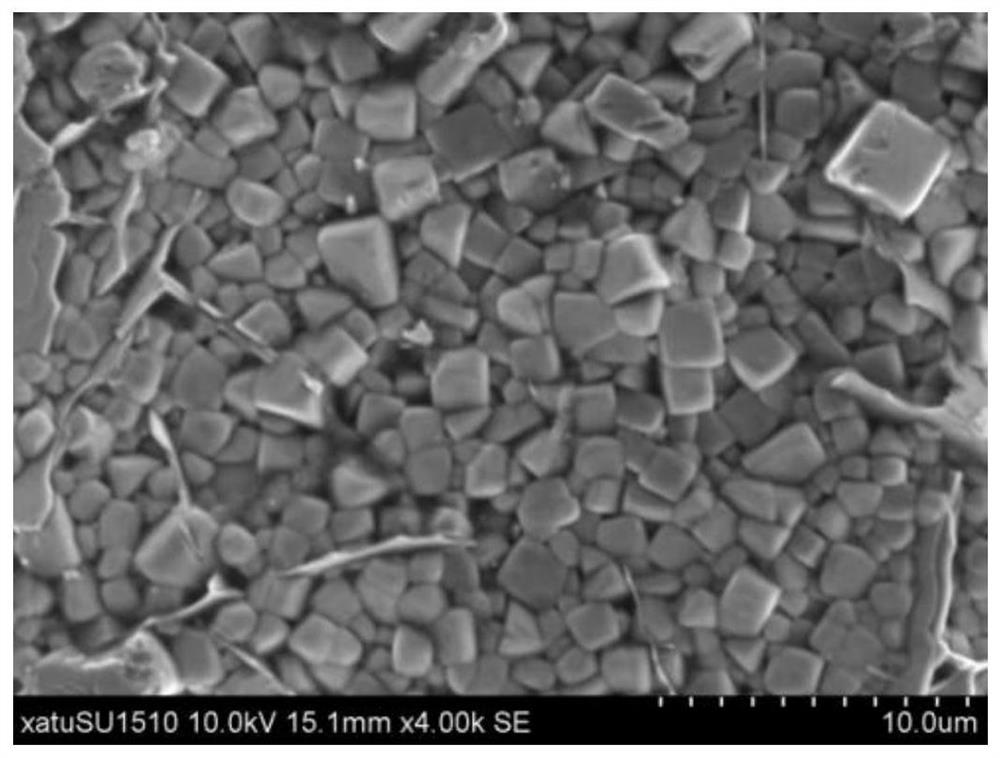

[0054] This example is a BNT-based energy storage ceramic material whose chemical formula is (Bi 0.5 Na 0.5 Ti 0.95 Al 0.025 O 3 ) 1-x (SrSc 0.5 Nb 0.5 O 3 ) x , where x=0.10, where x is the number of moles.

[0055] The analytically pure raw material Bi 2 O 3 , Na 2 CO 3 , TiO 2 , Al 2 O 3 , Nb 2 O 5 , SrCO 3 , Sc 2 O 3 Incubate in an oven at 120°C for 12 hours.

[0056] Weigh the raw material obtained in step 1 according to the stoichiometric ratio and pour it into a ball mill jar.

[0057] The raw materials obtained in step 2 were put into a planetary ball mill according to the mass ratio of raw materials: zirconium balls: anhydrous ethanol to 1:1:2 for a ball milling, and the ball milling time was 12h.

[0058] Pour the product of step 3 into a petri dish, put it into an oven at 60° C. to dry, and then sieve it with a 60-mesh sieve to separate the zirconium balls from the powder.

[0059] The powder obtained in step 4 was raised to 850 °C at 3 °C / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com