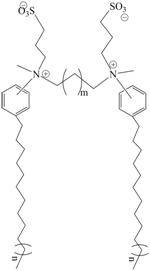

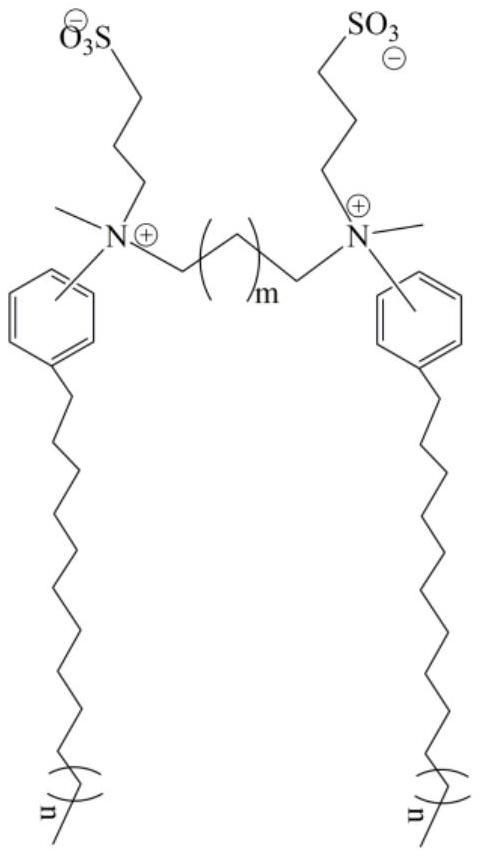

Preparation method of emulsified modified asphalt based on zwitterionic Gemini emulsifier

A technology of emulsifying modified asphalt and zwitterions, which is applied in the fields of sulfonate preparation, organic chemistry, and building components, etc. It can solve the problems of poor emulsifier wetting effect and large addition amount, achieve high emulsification effect and improve pressure resistance The effect of high strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

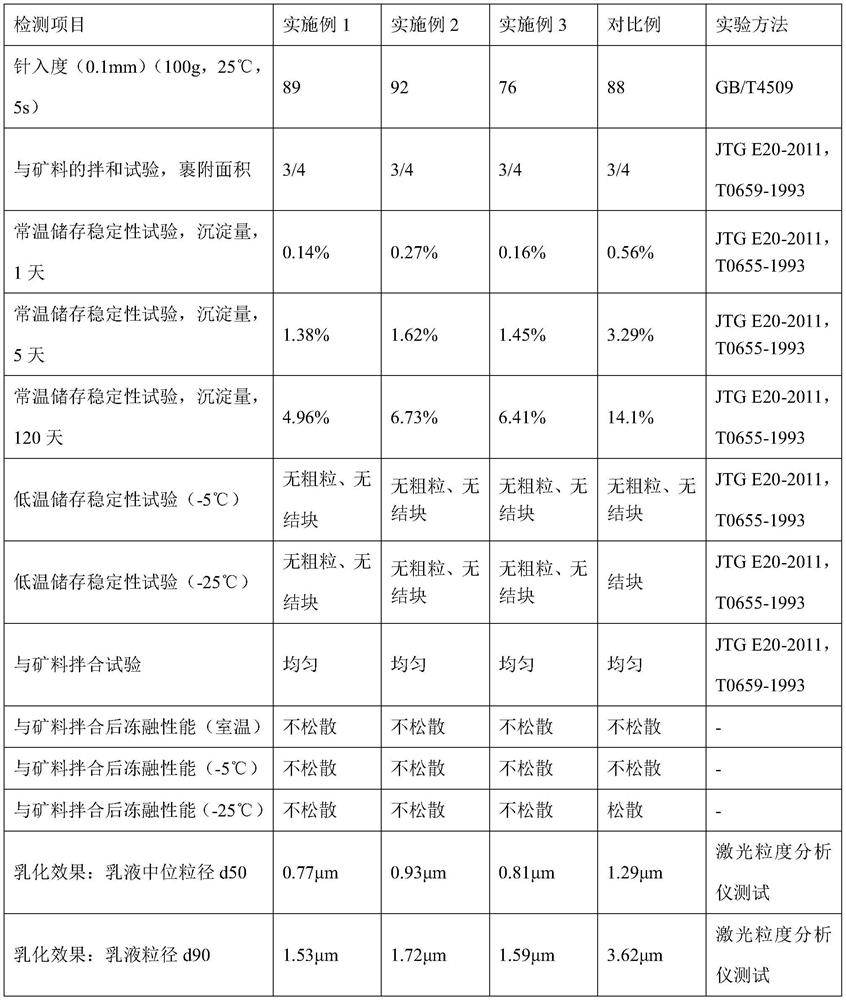

Examples

Embodiment 1

[0025] A kind of emulsified modified asphalt based on zwitterionic Gemini emulsifier, in parts by weight, its formula consists of: 65 parts of modified asphalt, 0.5 part of zwitterionic Gemini emulsifier, 6 parts of alumina sol (weight fraction is 20%, pH value is 5, the median particle size of alumina in the alumina sol is 50-60nm), 0.1 part of polyacrylamide, 1 part of calcium nitrite, 40 parts of water; wherein, the modified asphalt is The SBR modified asphalt, the SBR content in the SBR modified asphalt is 1%.

[0026] The preparation method of the emulsified modified asphalt of above-mentioned zwitterionic type Gemini emulsifier comprises the following steps:

[0027] Mix and stir the zwitterionic Gemini emulsifier, antifreeze, thickener, and water evenly, and heat to 55°C to obtain soap liquid; heat the modified asphalt to 138°C to obtain softened asphalt; separate the above soap liquid and softened asphalt at the same time Transported to the colloid mill, after uniform...

Embodiment 2

[0031] A kind of emulsified modified asphalt based on zwitterionic Gemini emulsifier, in parts by weight, its formula consists of: 60 parts of modified asphalt, 0.1 part of zwitterionic Gemini emulsifier, 3 parts of alumina sol (weight fraction is 30%, the pH value is 6, the median particle size of alumina in the alumina sol is 30-40nm), 0.2 parts of organic bentonite, 3 parts of calcium chloride, and 35 parts of water; wherein, the modified asphalt is SBS Modified asphalt, the SBS in the SBS modified asphalt is 3% by weight.

[0032] The preparation method of the emulsified modified asphalt of above-mentioned zwitterionic type Gemini emulsifier comprises the following steps:

[0033] Mix and stir the zwitterionic Gemini emulsifier, antifreeze, thickener, and water evenly, and heat to 40°C to obtain soap liquid; heat the modified asphalt to 125°C to obtain softened asphalt; separate the above soap liquid and softened asphalt at the same time Transported to the colloid mill, a...

Embodiment 3

[0037] A kind of emulsified modified asphalt based on zwitterionic Gemini emulsifier, in parts by weight, its formula consists of: 62 parts of modified asphalt, 0.3 part of zwitterionic Gemini emulsifier, 4 parts of alumina sol (weight fraction is 25%, the pH value is 7, the median particle size of alumina in the alumina sol is 30-50nm), 0.15 parts of carboxymethyl starch, 2 parts of sodium nitrite, 38 parts of water; wherein, the modified asphalt It is SBS modified asphalt, and the weight fraction of SBS in SBS modified asphalt is 1.53%.

[0038] The preparation method of the emulsified modified asphalt of above-mentioned zwitterionic type Gemini emulsifier comprises the following steps:

[0039] Mix and stir the zwitterionic Gemini emulsifier, antifreeze, thickener, and water evenly, and heat to 65°C to obtain soap liquid; heat the modified asphalt to 160°C to obtain softened asphalt; separate the above soap liquid and softened asphalt at the same time Transported to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com