A method for automatic deviation correction control of cold-rolled strip continuous annealing heating furnace

A technology of automatic deviation correction and control method, which is applied in the direction of heat treatment process control, heat treatment furnace, neural learning method, etc., and can solve the problems of economic loss, production line downtime, strip broken strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The following will describe the production process of a roll of automobile outer panels with a thickness of 0.995 mm as an example.

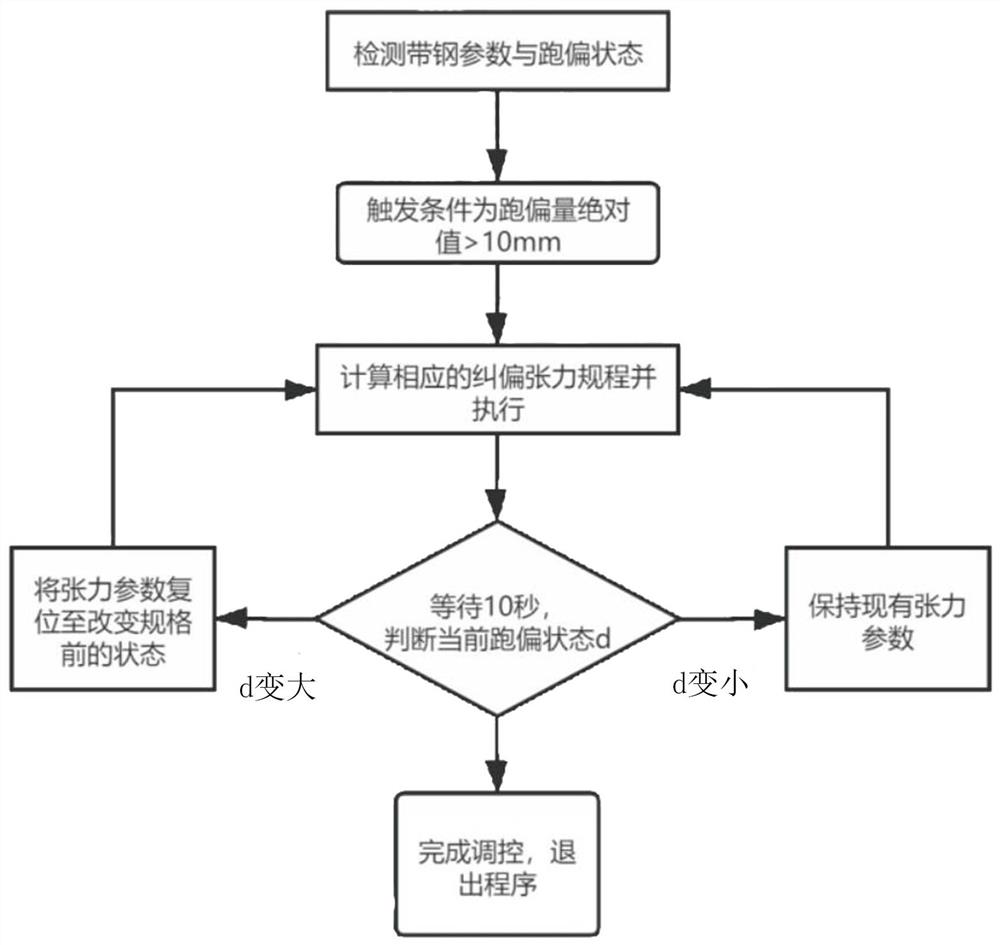

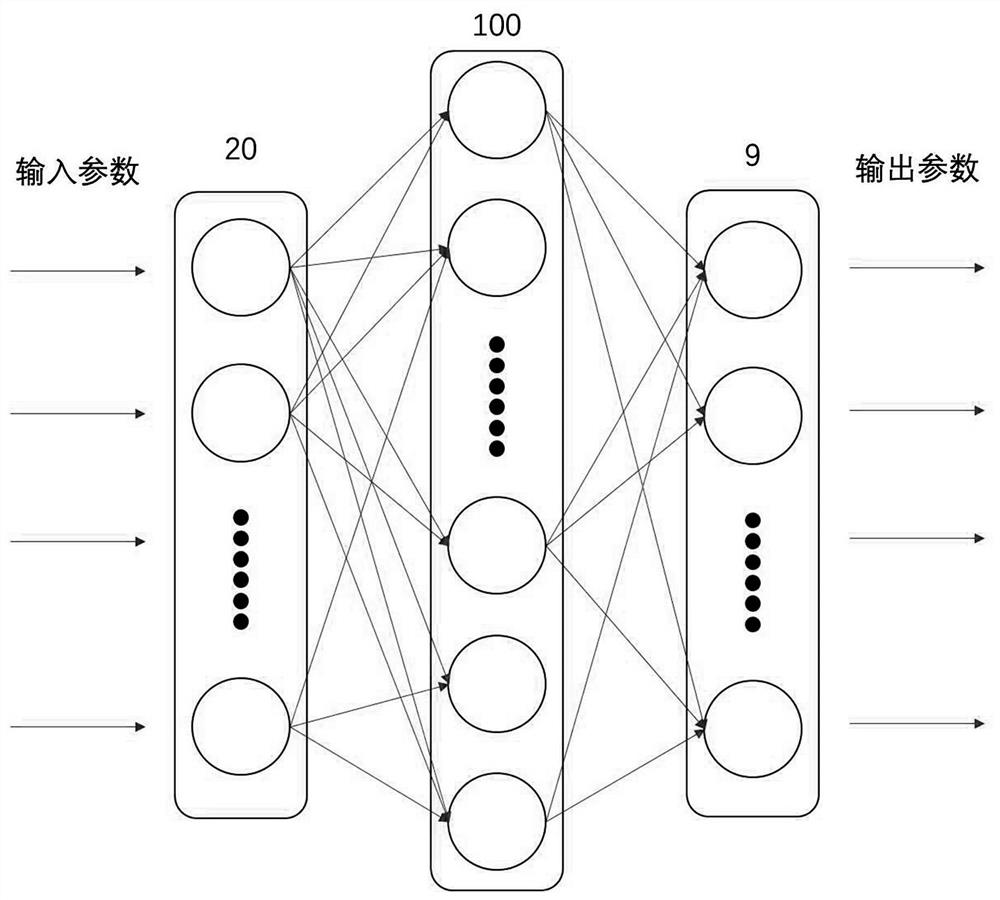

[0045] A method for automatic deviation correction control of a continuous annealing heating furnace for cold-rolled strip steel, comprising the following steps:

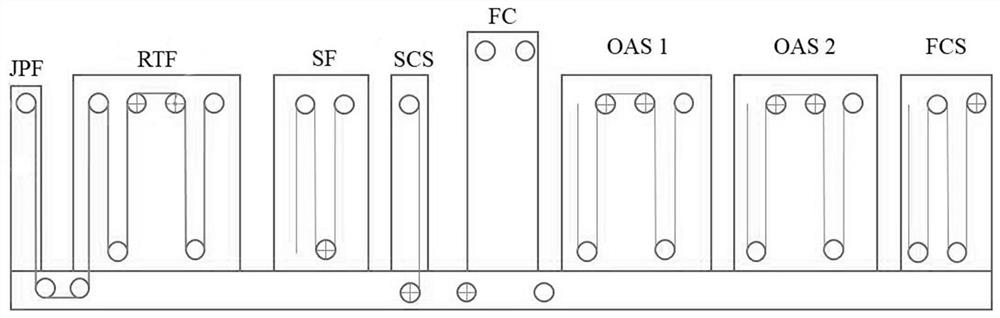

[0046] Step 1: Real-time monitoring of the relevant data of the PLC system of the continuous annealing heating furnace. The product specification of the automobile outer panel is 0995mm, the width is 936mm, the steel is AP0941D1, the heating curve code is S74, and the tension values of each area of the continuous annealing heating furnace are respectively 74.5KN, 68.1KN, 62.8KN, 77.4KN, 71.9KN, 91.4KN, 94.6KN, 99.3KN, 109.3KN, the deviation of each area of the continuous annealing heating furnace, that is, the correction amount of the oil cylinder in each area and the belt in each area The sum of steel deviation corrections is -4mm, -2mm, -23mm, 15mm, 1mm, -28mm, -13mm re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com