Agricultural flax scutching equipment

A technology of flax and equipment, which is applied in the field of agricultural flax beating equipment, can solve the problems such as not easy to collect flax fiber, and achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

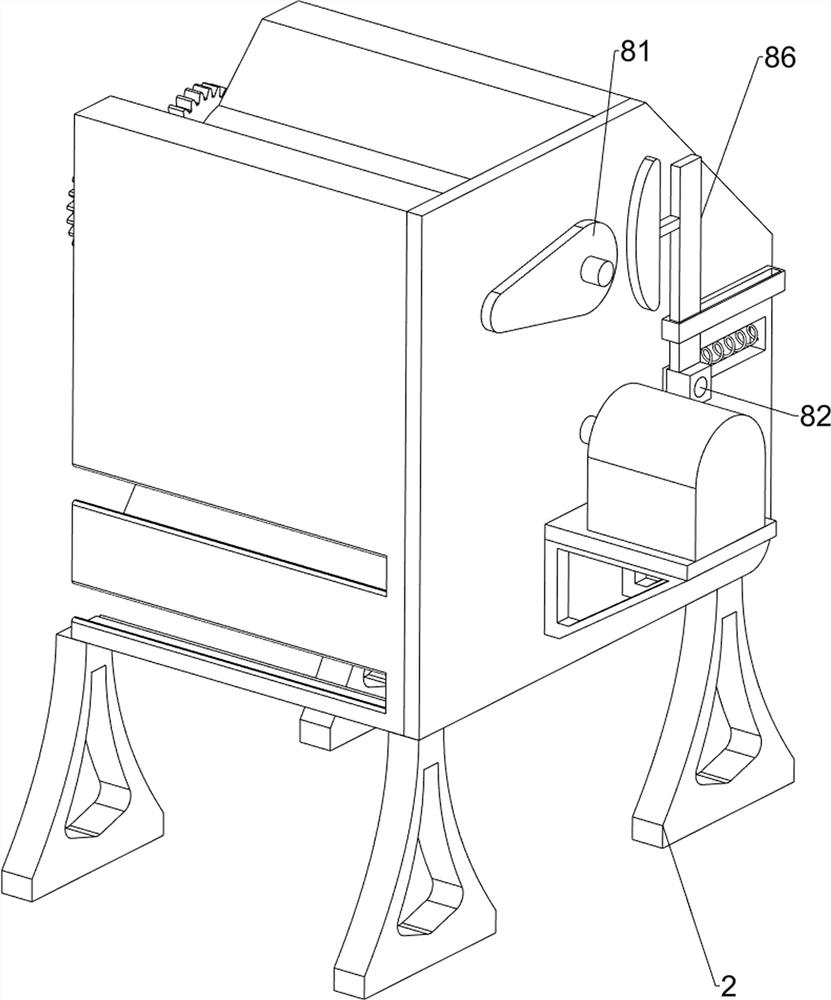

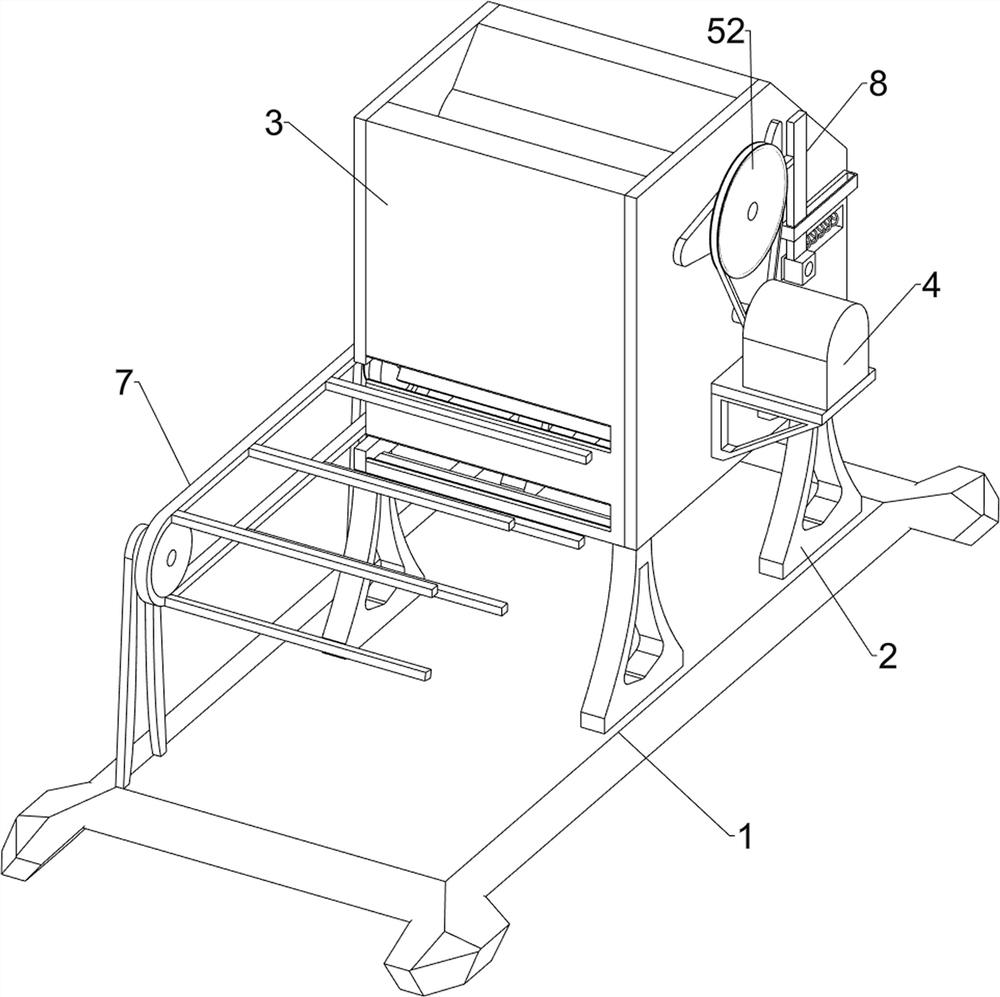

[0022] An agricultural flax beating equipment, such as Figure 1-5 As shown, it includes a base 1, a support frame 2, a chassis 3, a geared motor 4, a material transfer assembly 5 and a hemp processing assembly 6, and four support frames 2 are arranged symmetrically on the right side of the top of the base 1, and the tops of the surrounding support frames 2 pass through The bolt is provided with a casing 3, and a reduction motor 4 is installed on the front side of the casing 3. The upper part of the inner side of the casing 3 is provided with a feeding assembly 5, and the lower part of the inner side of the casing 3 is provided with a beating assembly 6. The feeding assembly 5 and the beating assembly 6 are all connected to the deceleration The output shaft of the motor 4 is connected.

[0023] The transmission assembly 5 includes a transmission wheel 51, a first rotating device 52 and a first gear 53. The upper part of the inner side of the cabinet 3 is symmetrically rotated ...

Embodiment 2

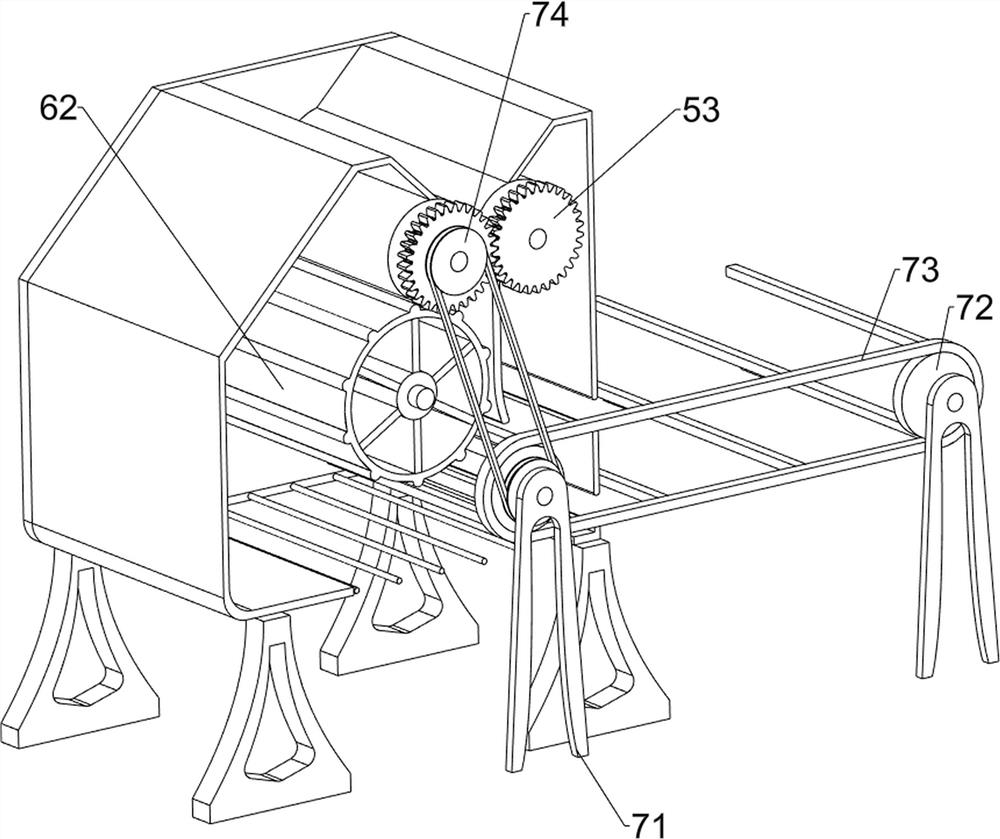

[0029] On the basis of Example 1, such as figure 1 and Figure 3-5 As shown, a collection assembly 7 is also included. The left rear side of the top of the base 1 is provided with a collection assembly 7. The upper part of the collection assembly 7 is connected to the transmission wheel 51 on the right side. The collection assembly 7 includes a bearing seat 71, a transmission wheel 72, and a collection belt. 73 and the second transmission device 74, base 1 top left rear side left and right sides are symmetrically equipped with bearing seat 71, all rotation type is provided with transmission wheel 72 in the bearing seat 71, is wound with collection belt 73 on the transmission wheel 72 of left and right sides, right A second transmission device 74 is connected between the transmission wheel 72 on the side and the transmission wheel 51 on the right.

[0030]Also comprise cleaning assembly 8, cabinet 3 right parts are provided with cleaning assembly 8, cleaning assembly 8 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com