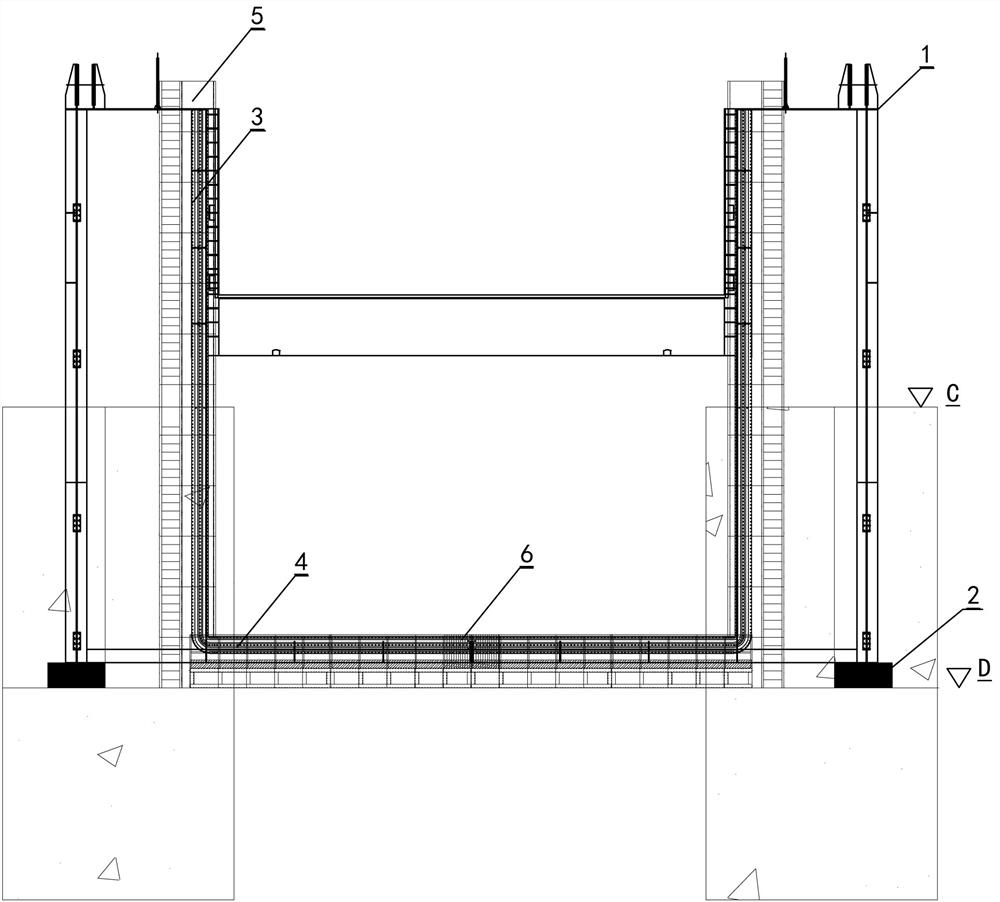

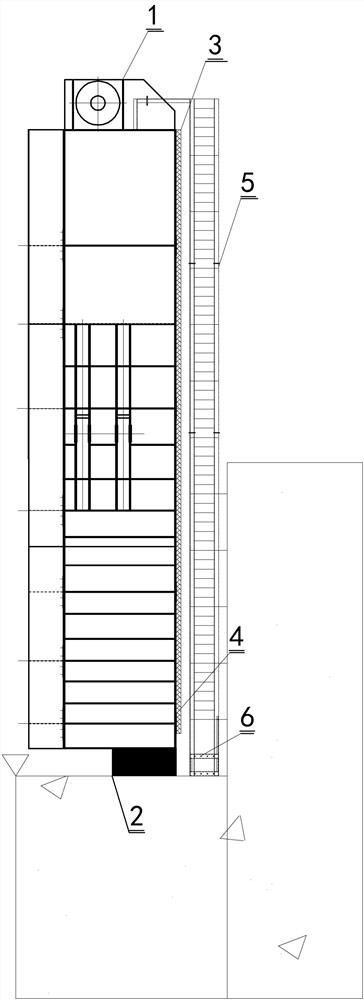

Pressurizing water-stop efficient dismounting device and method for large-scale plane gate of vertical ship lift

A technology of vertical ship lift and plane gate, which is applied in vertical lifting of ship machinery, ship lifting device, construction, etc. The effect of high content and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

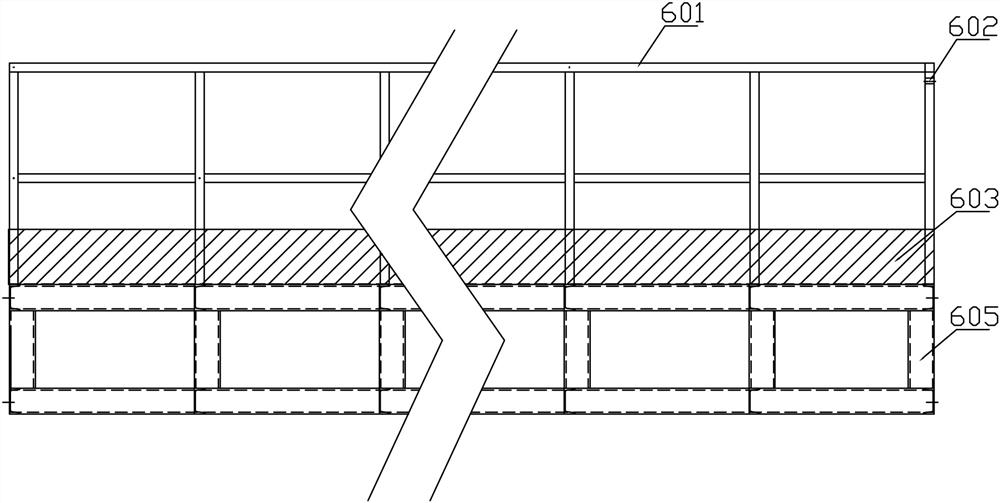

[0066] The method for disassembling and replacing the pressurized water-stop high-efficiency disassembly device of the large plane gate of the vertical ship lift includes the following steps:

[0067] Step 1: According to the structural characteristics of the door body and the pressurized water-stop rubber and pressure plate, the characteristics of the parking condition of the door body when the water-stop is replaced, and the characteristics of the permanent structure around the door body, design and manufacture the corresponding water-stop replacement platform on the side of the pressurized water-stop 5. Bottom water stop replacement platform for pressurized water stop 6. Water stop pressure plate removal device 7. Pressurized water stop connection device 8;

[0068] It is necessary to fully consider the structural characteristics and use requirements of each designed unit to ensure that the designed special construction platforms and auxiliary tooling can achieve the design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com