Non-combustible vacuum heat-insulating decorative plate and heat-insulating wall body formed by non-combustible vacuum heat-insulating decorative plate

A vacuum insulation and decorative panel technology, applied in building structure, floor, covering/lining, etc., can solve problems such as inability to meet fire protection requirements, flammability, etc., and achieve the effects of convenient construction, low cost, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

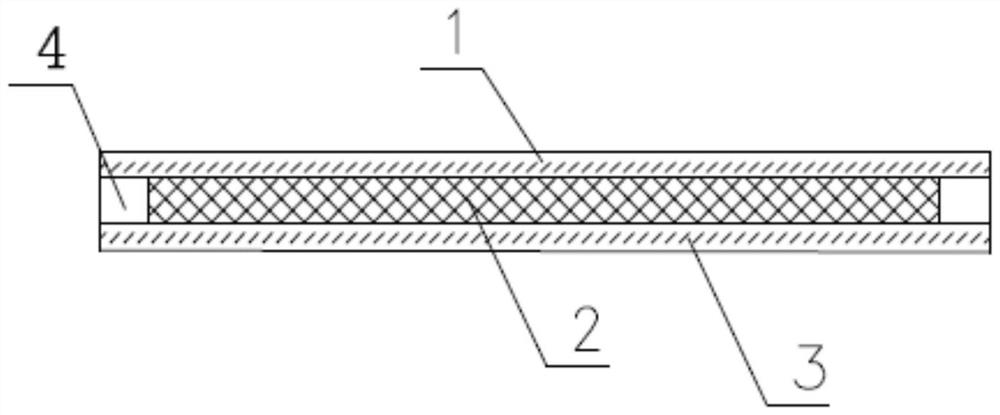

[0028] The non-combustible vacuum insulation decorative panel of this embodiment includes: a VIP panel 2, non-combustible panels symmetrically fixed on both sides of the VIP panel 2, the VIP panel 2 is centrally arranged between the non-combustible panels on the two sides, and the VIP panel The periphery of 2 adopts solid glue 4 to seal.

[0029] A groove is formed between the periphery of the VIP board and the periphery of the non-combustible boards on both sides, and the solid glue 4 fills the groove and forms a plane on the side, so that the VIP board 2 and the non-combustible boards on both sides The plates form a closed non-combustible unit.

[0030] The solid glue is preferably flame-retardant glue mixed with inorganic fibers, and the inorganic fibers are used to increase its strength and bonding effect. Other flame-retardant or non-combustible glues in the prior art can also be used.

[0031] The non-combustible board is calcium-silicon board or marble board or cerami...

Embodiment 2

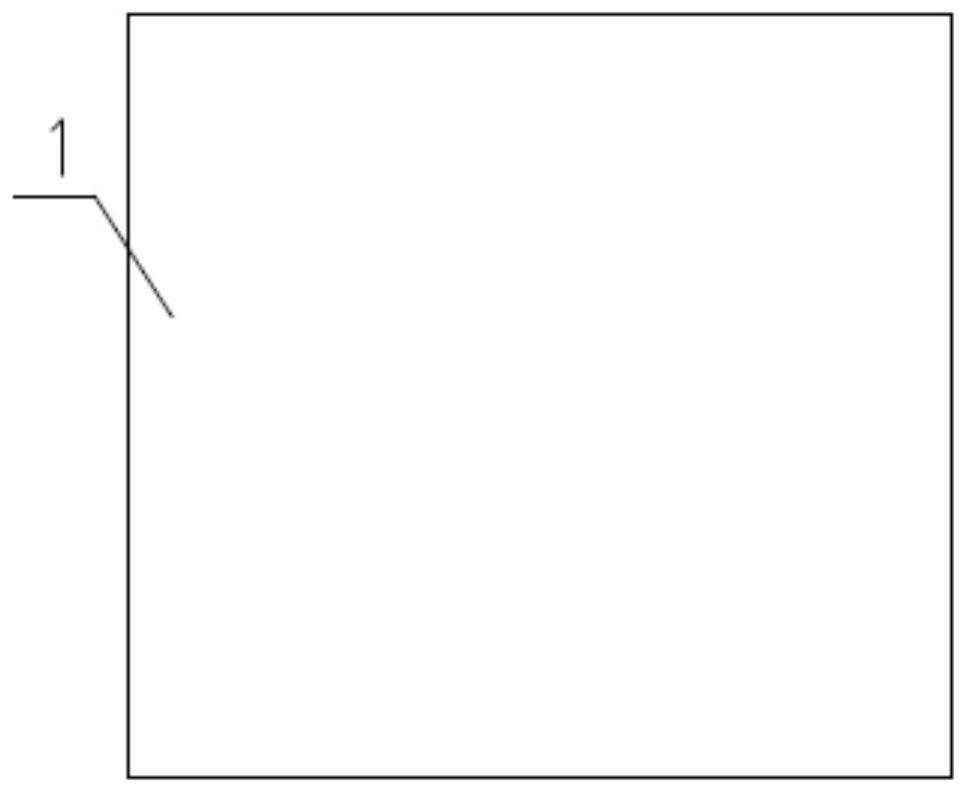

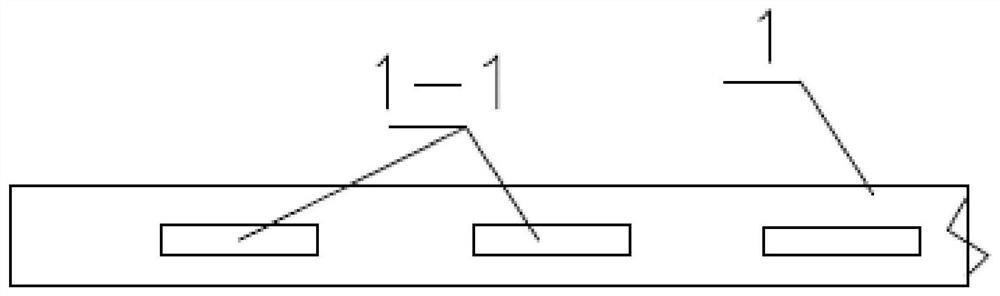

[0036] A thermal insulation wall surface using the non-combustible vacuum insulation decorative panel in the above-mentioned embodiment 1, comprising the vacuum insulation decorative panel fixed on the wall and spliced adjacently, and the two vacuum insulation decorative panels spliced adjacently The plates are fixed to each other by metal connectors 5 fitting in said mounting grooves.

[0037] The metal connecting piece 5 includes an insert 51 and a fixing piece 52; the insert 51 includes a base body, and tabs 511 extend from the top of the base body to the front and rear sides respectively, and the pair of tabs 511 are respectively inserted into a pair of adjacent vacuum insulation decorations. In the mounting groove 1-1 of the board; a pair of parallel first chute 512 is distributed on the substrate; the section of the fixing piece 52 is L-shaped, and a pair of parallel second chute 521 is distributed on the vertical surface of the fixing piece 52, The pair of second ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com