Dry powder plastering mortar made from ceramic waste residues and manufacturing method thereof

A technology for ceramic waste slag and plastering mortar is applied in the field of dry powder plastering mortar. The dry powder plastering mortar can solve problems such as air pollution, environmental hazards, and impact on people's health, and achieve the effects of stable quality and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

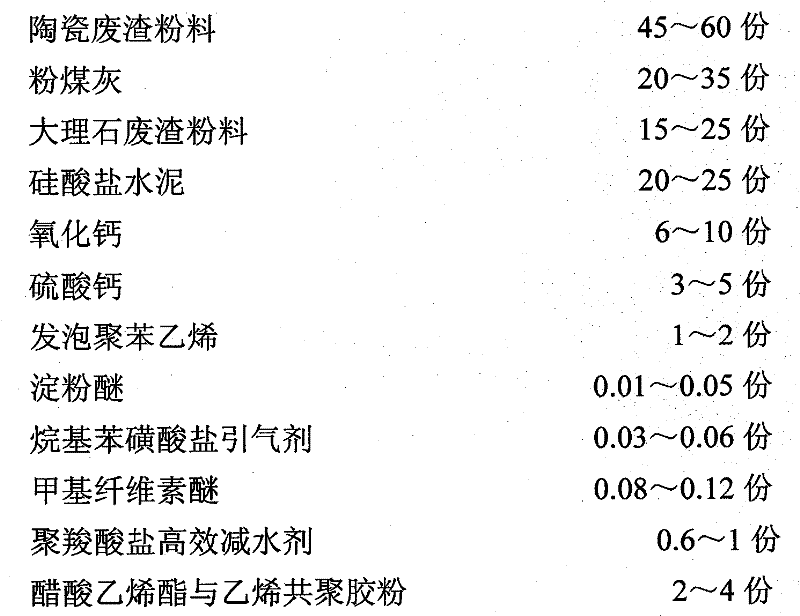

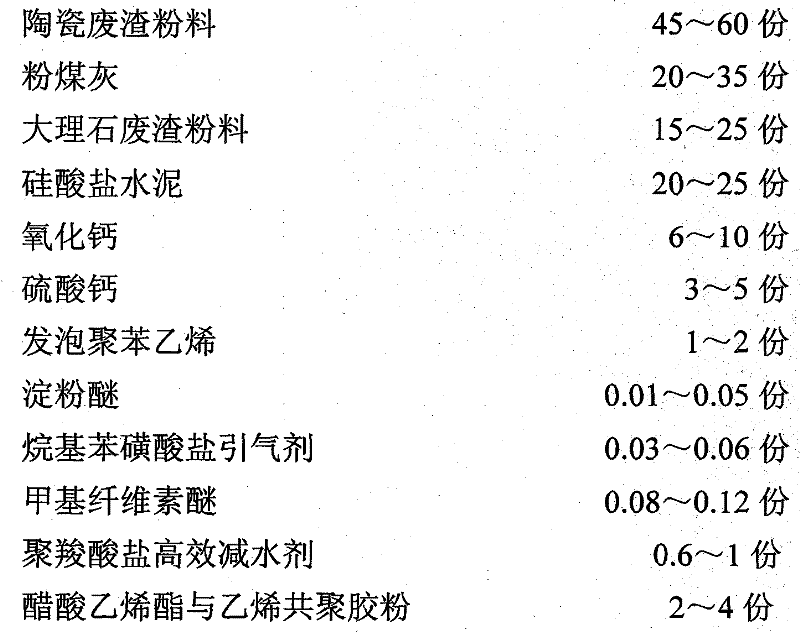

Embodiment 1

[0035] The waste porcelain mud generated during the production of ceramics is dehydrated into solid waste and damaged blanks, damaged waste products that have not been calcined and glazed, semi-finished products that have been calcined and glazed, waste products with damage or cracks, waste architectural ceramics and waste The mixture of sanitary ceramic residues is crushed, sorted, and magnetically separated to remove waste metals, and then dried, wheel-milled, and sorted to make a powder with a particle size of less than 1.6mm;

[0036] A kind of volcanic ash-like mixed material formed by burning coal at high temperature to generate electricity is a kind of solid waste discharged from coal-fired power plants. The fineness is generally below 45um and then dried and screened to make fly ash powder.

[0037] The fine powder and leftover waste discharged during the production and cutting process of marble and granite are crushed, sorted and pulverized, and then dried and wheel-mi...

Embodiment 2

[0041] Get the ceramic waste slag powder 52kg of embodiment 1, fly ash 26kg, marble waste slag powder 20kg, Portland cement 22kg, particle diameter be the calcium oxide 8kg of 0.2mm, calcium sulfate 4kg, expanded polystyrene 1.5kg, Starch ether 0.03kg, alkylbenzene sulfonate air-entraining agent 0.04kg, methyl cellulose ether 0.1kg, polycarboxylate superplasticizer 0.8kg, vinyl acetate and ethylene copolymer rubber powder 3kg, the above raw materials were used The double-shaft paddle mixing mixer is used to mix evenly to make dry powder plastering mortar products. After testing, the compressive strength: 10Mpa, water retention: 70%, bonding strength: 0.63Mpa, air content: 12%, shrinkage rate: 0.25%, consistency: 70mm, all meet the local standards of Guangzhou and Shenzhen.

Embodiment 3

[0043] Get embodiment 1 ceramic waste slag powder 60kg, fly ash 20kg, marble waste slag powder 25kg, Portland cement 20kg, particle diameter is the calcium oxide 10kg of 0.2mm, calcium sulfate 3kg, expanded polystyrene 2kg, starch Ether 0.01kg, alkylbenzene sulfonate air-entraining agent 0.06kg, methyl cellulose ether 0.08kg, polycarboxylate superplasticizer 1kg, vinyl acetate and ethylene copolymer rubber powder 4kg, the above raw materials are used in biaxial The paddle mixing mixer is used to mix evenly to make dry powder plastering mortar products. After testing, the compressive strength: 8.5Mpa, water retention: 75%, bonding strength: 0.6Mpa, air content: 11.5%, shrinkage rate: 0.3%, consistency: 75mm, all meet the local standards of Guangzhou and Shenzhen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com