Ultra-thin stone decorative board suitable for heat preservation and installation method thereof

An ultra-thin, decorative panel technology, applied in the processing of building materials, covering/lining, construction, etc., can solve the problems of reducing the overall thermal insulation performance of the vacuum insulation panel, affecting the flatness of the product plane, and detrimental to building energy conservation. Conducive to building energy saving, improve overall thermal insulation performance, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The ultra-thin stone decorative board suitable for heat preservation in this embodiment includes: an ultra-thin stone slab 3, a VIP 6 bonded on the inner side of the ultra-thin stone slab by an adhesive, and a VIP 6 bonded on the inner side of the VIP by an adhesive The bottom plate 4.

[0061] A plurality of pits 6-2 and / or protrusions 6-1, or a plurality of strip-shaped grooves 6-3, or grid-shaped grooves 6-4 are distributed on the inner and outer surfaces of the VIP.

[0062] Such as Figure 17 , if the ultra-thin stone slab 3 is a flat plate, the distribution of each pit and protrusion or a plurality of bar-shaped grooves, or grid-shaped grooves, after putting the film bag with the core material into the vacuum chamber to complete vacuuming and sealing After entering the normal pressure environment, the VIP can be made to be a flat plate body, that is, the tension of the film material on the inner and outer surfaces of the VIP can be made consistent, and the bendin...

Embodiment 2

[0073] On the basis of Embodiment 1, this embodiment has the following modifications:

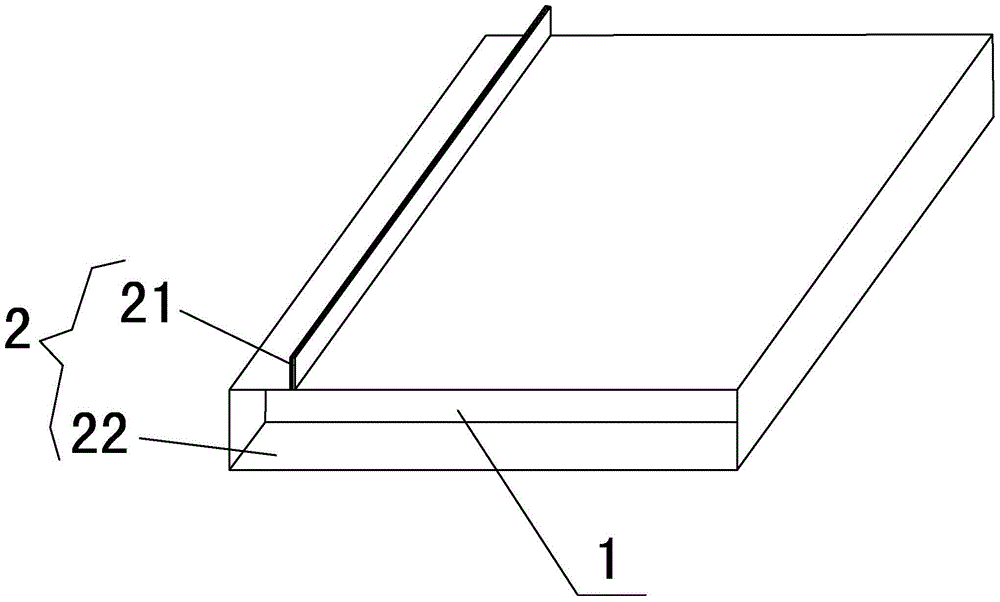

[0074] Such as Figures 6 to 8 , the packaging film 2 is two sheets connected end to end, and the corresponding two end to end joints 21 are on the upper or lower plane of the core material at the same time, or on the edge of the core material 1 at the same time on, or on the upper and lower planes of the core material 1 respectively.

Embodiment 3

[0076] The ultra-thin stone decorative board suitable for heat preservation of the above-mentioned embodiment comprises the following steps:

[0077] A. After covering the upper and lower planes and the left and right sides of the core material with at least one packaging film, the head and tail are hot-melt connected, and the head and tail connection is not on the left and right sides of the core material;

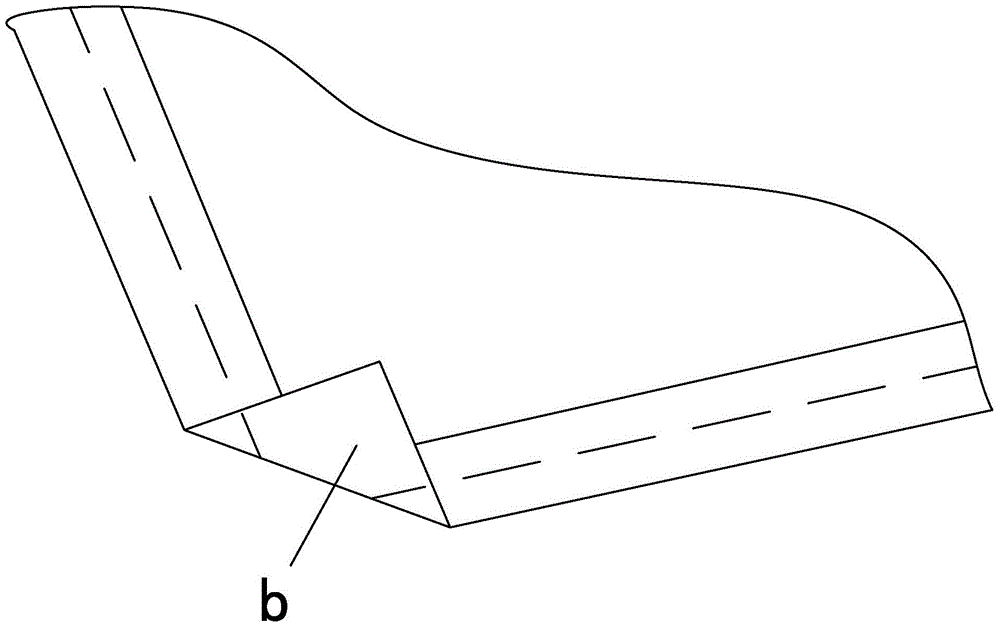

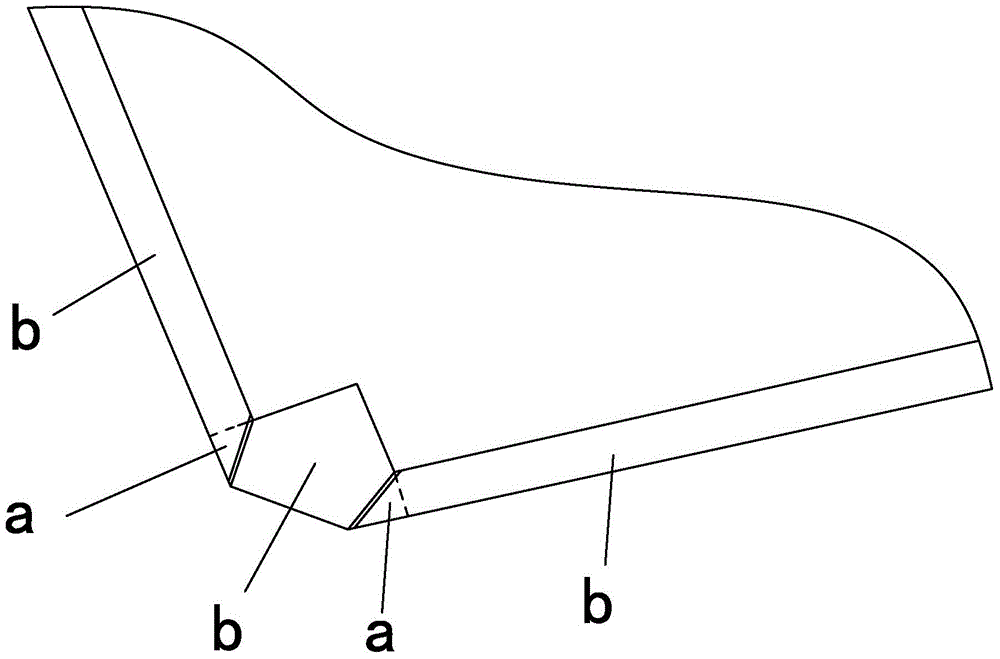

[0078] B. The extensions of the packaging film that extend out of the front and rear sides of the core material are folded symmetrically toward the center of the inner side along the four edges of the front and rear sides of the core material; during the folding process, the The part of the opening of the extension part adjacent to the short side is M-shaped;

[0079] C. After being folded over, the parts of the extension part adjacent to the front and rear sides of the core material are respectively closely attached to the front and rear sides of the core material;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com