Assembling device and method for split bolts of steel plate composite wall

A technology for pulling bolts and assembling devices, which is applied in the treatment of walls, building materials, construction, etc., can solve the problems of high safety performance in the assembly process and high assembly quality of the corrugated steel plate composite wall, and achieves good assembly quality, easy batch assembly, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

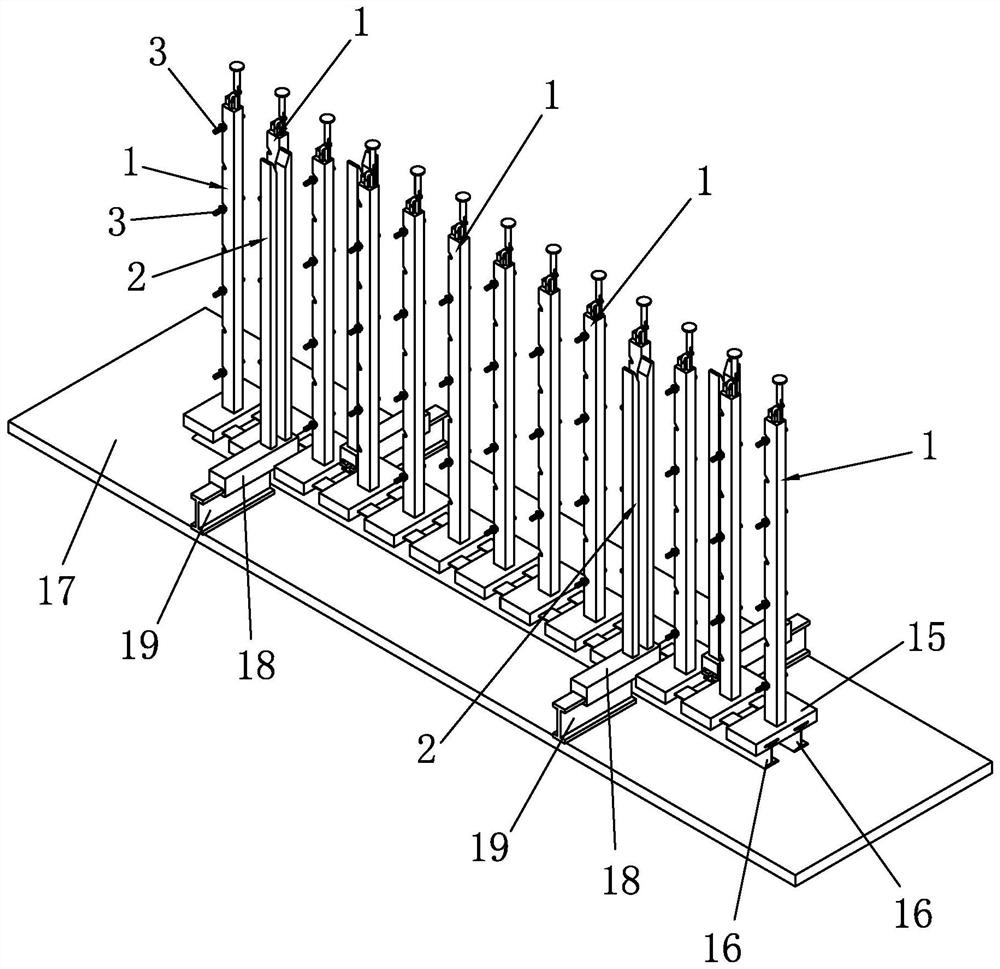

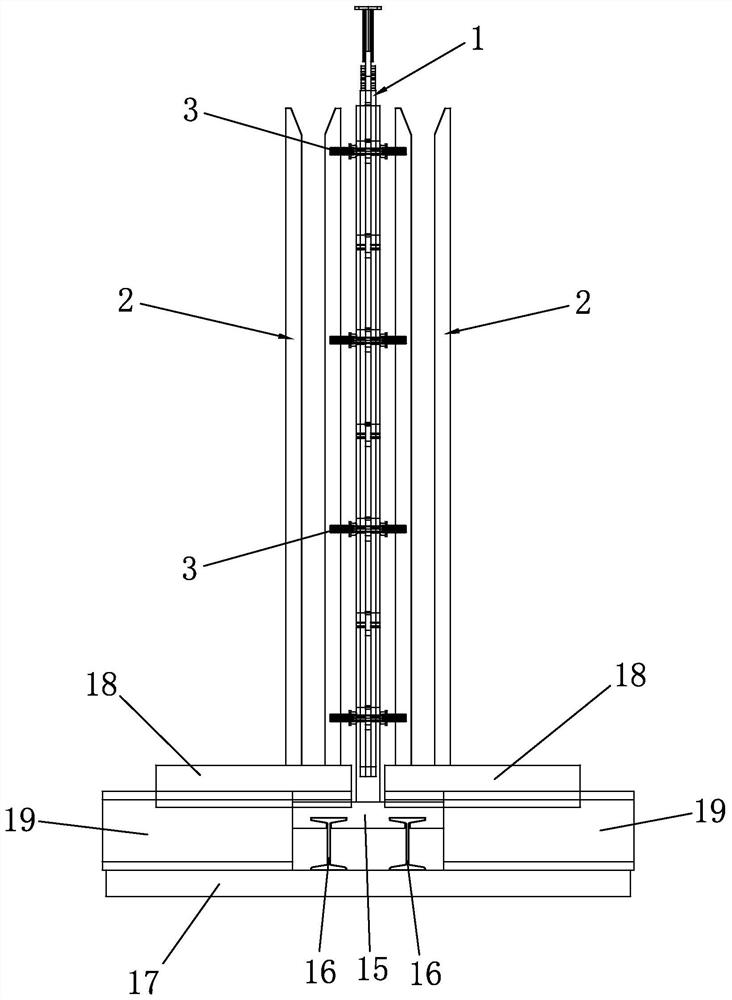

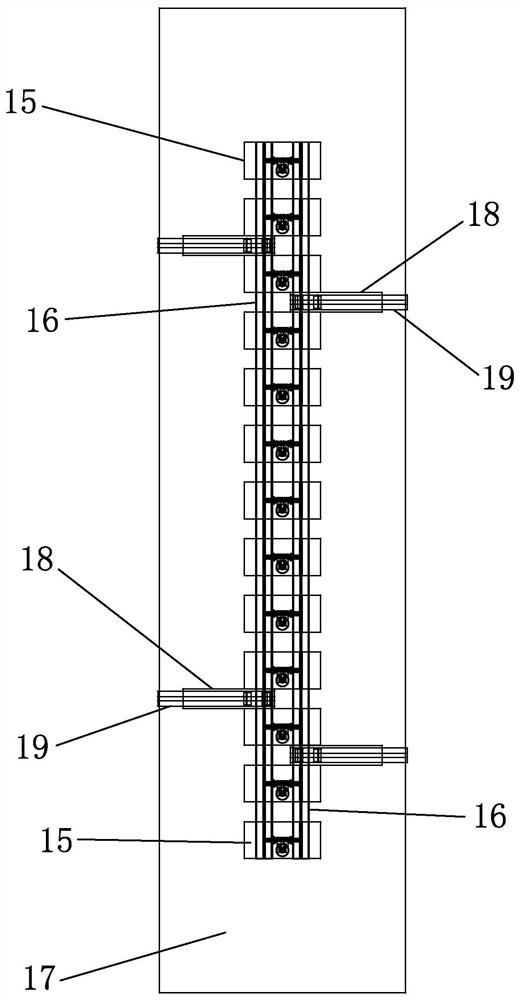

[0056] like Figure 1 to Figure 15 As shown, it is a steel plate combined wall tie bolt assembly device of the present invention, including a tie bolt positioning device 1 and a single corrugated steel plate positioning device 2, the tie bolt positioning device 1 is used to limit the tie bolt 3, and the single corrugated steel plate The positioning device 2 is used to limit a single piece of corrugated steel plate 4 so that the through hole of the corrugated steel plate 4 is aligned with the tension bolt 3 . The single corrugated steel plate 4 is installed on the pull bolt 3 by directional movement of the single corrugated steel plate positioning device 2 in the direction of the pull bolt positioning device 1 .

[0057] The pull bolt positioning device 1 includes a pull bolt positioning rod 5, and the pull bolt positioning rod 5 is provided with an opening 6 that is inclined upward. The pull bolt 3 is limited on the pull bolt positioning device 1 .

[0058] Since the pull bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com