a hydraulic system

A technology of hydraulic cylinder and oil circuit, applied in the application field of flexible mechanism in hydraulic system, can solve the problems of single force supply, increase strength, difficult to realize buffer support, etc., to improve space utilization, enhance bending resistance, Strong supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

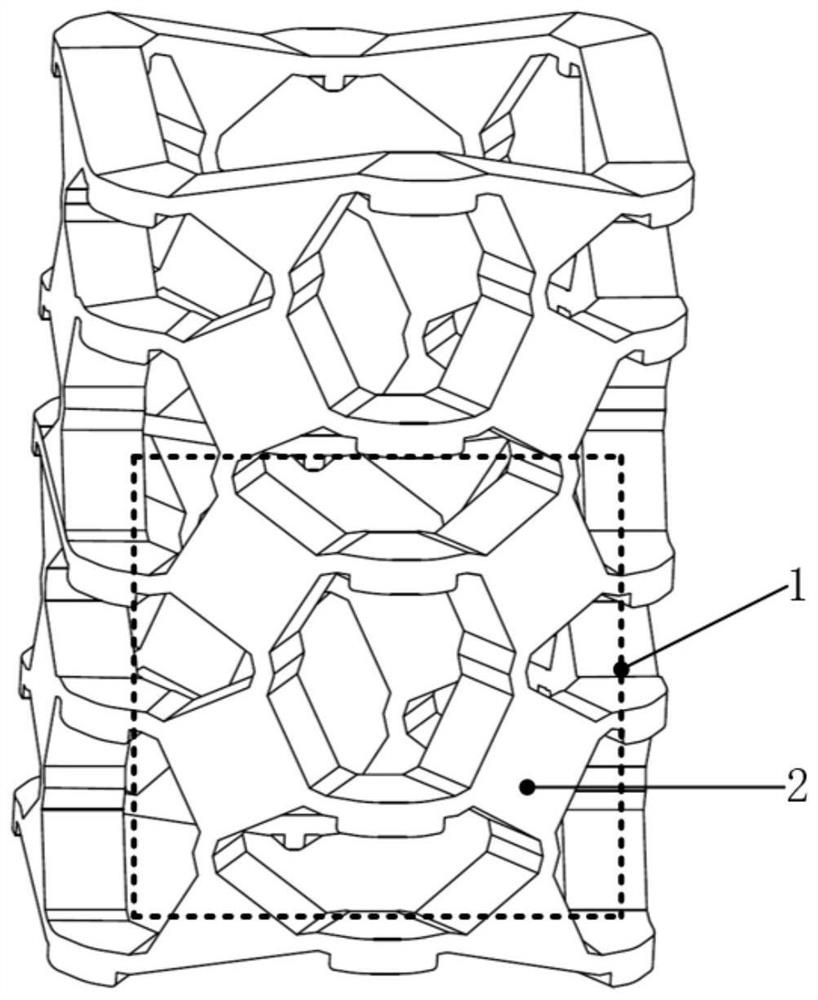

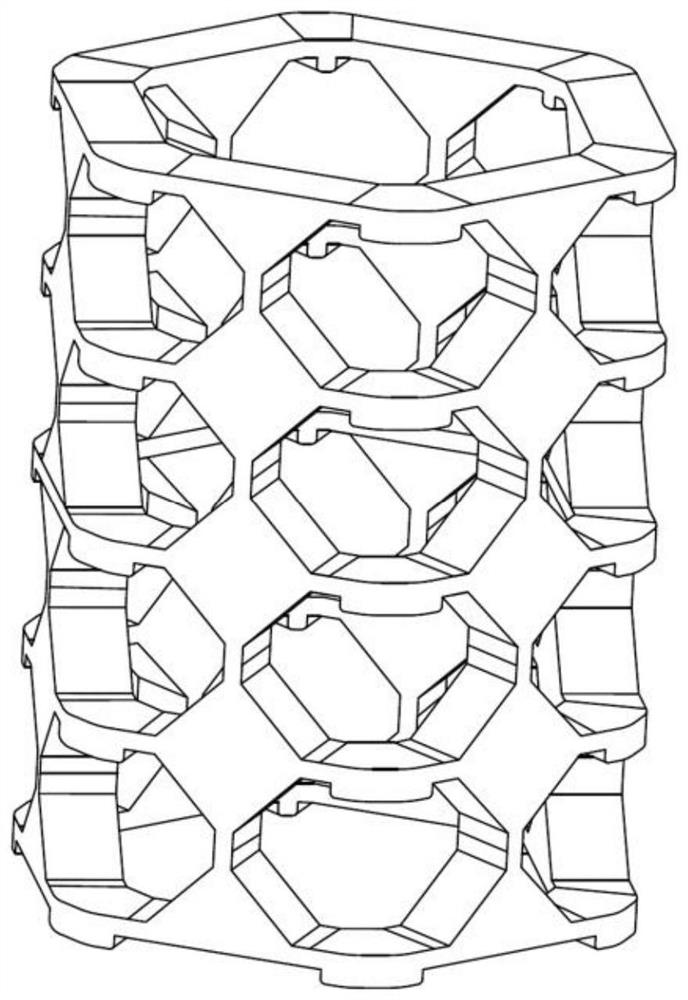

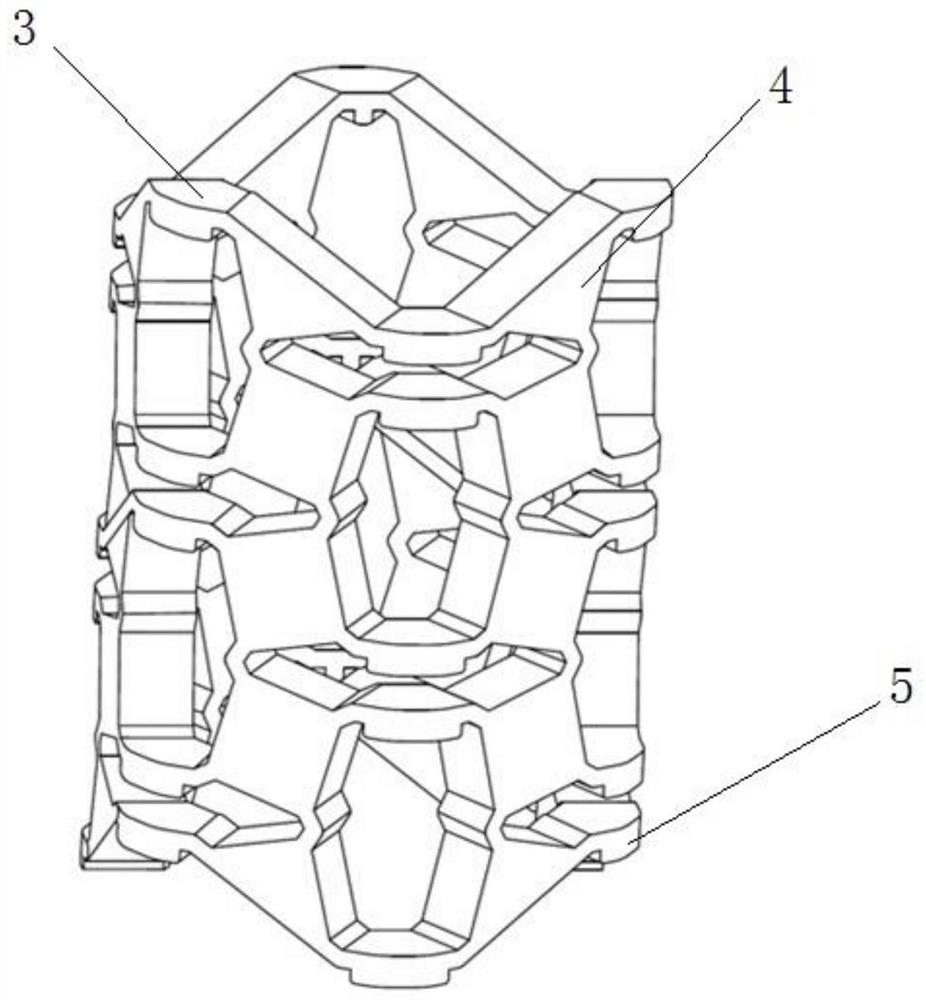

[0050]As shown in the figure: a hydraulic control system, including: an oil tank 13, an oil pump 14, a filter 15, a relief valve 16, a first solenoid valve 17, a second solenoid valve 18, a third solenoid valve 19, and a fourth solenoid valve 20. One-way valve 21, first hydraulic cylinder 22, second hydraulic cylinder 23, third hydraulic cylinder 24;

[0051] The oil tank 13, the filter 15, the oil pump 14 and the one-way valve 21 are connected in sequence to form an oil delivery circuit; the downstream of the one-way valve 21 is provided with a first oil circuit and a second oil circuit, and the first oil circuit is provided with a first solenoid valve 17, A second solenoid valve 18 is provided on the second oil circuit, the first oil circuit is connected to one end of the first to third hydraulic cylinders, the second oil circuit is connected to the other ends of the first to third hydraulic cylinders; the first oil circuit is connected to the first hydraulic cylinder The oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com