a bearing assembly

A technology of bearing components and bearings, which is applied in the direction of bearing components, bearing assembly, bearings, etc., can solve problems such as idling, reduce transmission efficiency, and affect rotation accuracy, so as to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

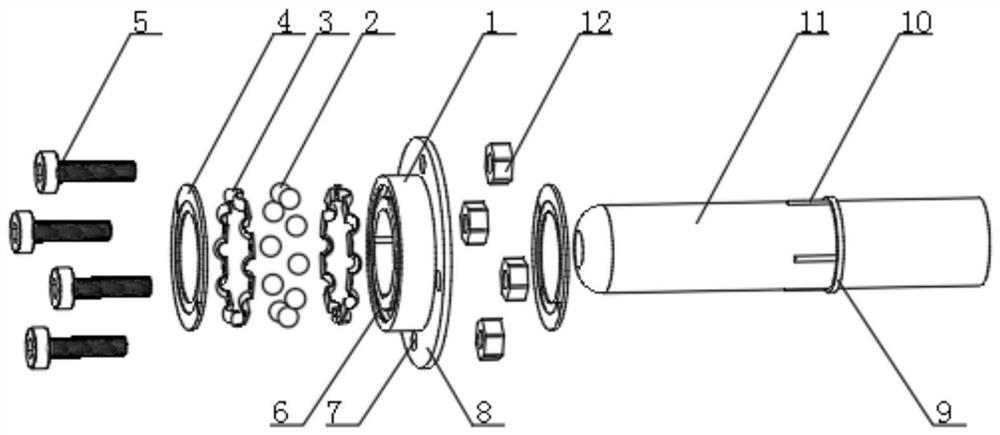

[0027] like figure 1 As shown, a bearing assembly includes an outer ring bearing 1, the outer surface of the side end of the outer ring bearing 1 is provided with a limiting member 8, the outer surface of the limiting member 8 is embedded with a fixing hole 7, and the outer surface of the side end of the limiting member 8 is The surface is provided with a hexagonal nut 12, the outer surface of the side end of the hexagonal nut 12 is provided with a transmission shaft 11, the outer surface of the transmission shaft 11 is embedded with a pin 10, the outer surface of the side end of the pin 10 is provided with a fixing ring 9, and the outer surface of the outer ring bearing 1 is provided. The inner outer surface is embedded with a slot 6, the outer surface of the side end of the outer ring bearing 1 is provided with a ball 2, the outer surface of the side end of the ball 2 is provided with a cage 3, and the outer surface of the side end of the cage 3 is provided with a sealing rin...

Embodiment 2

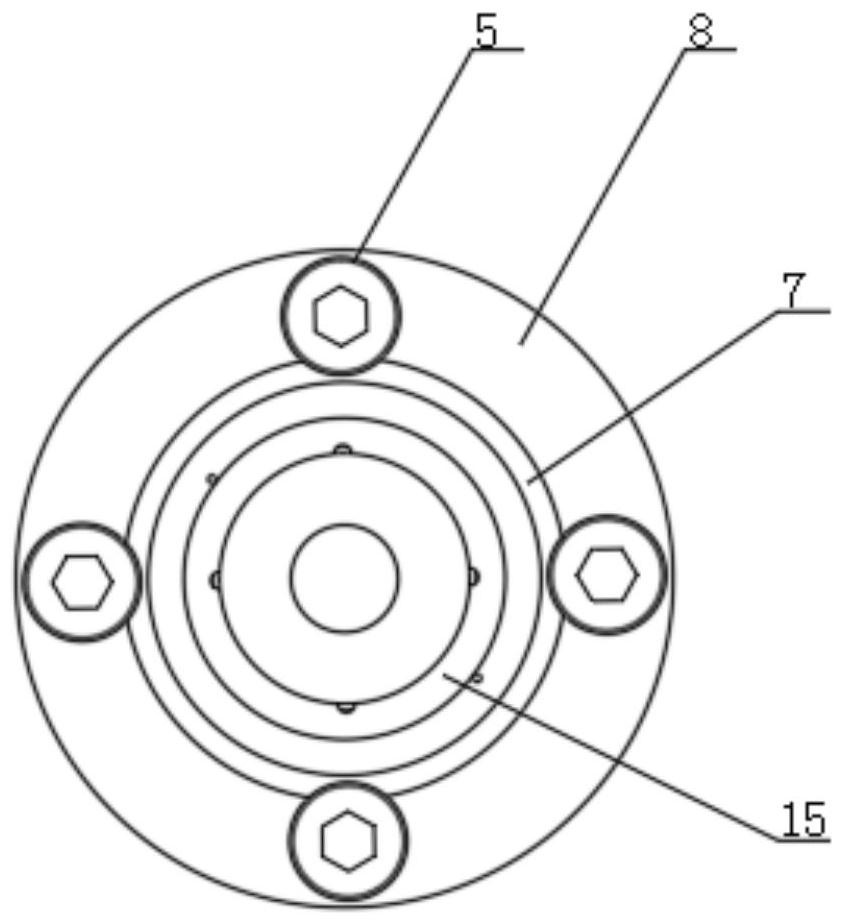

[0029] On the basis of Example 1, as figure 1 , 4 As shown, the inner side of the outer ring bearing 1 is provided with an inner ring bearing 15, and there is an active connection between the two, the outer ring bearing 1 and the inner ring bearing 15 are coaxial, and the connection between the outer ring bearing 1 and the inner ring bearing 15 Balls 2 are provided, and the balls 2 and the two are movably connected. The balls 2 are tangent to the inner surface of the outer ring bearing 1 and the outer surface of the inner ring bearing 15. The number of the balls 2 is several, and they are arranged in a circular array. The inner ring bearing 15 and the outer ring bearing 1 can slide relative to each other through the balls 2, the limiter 8 is fixedly connected with the outer ring bearing 1, the fixing hole 7 runs through the limiter 8, and the number of the fixing holes 7 is four The number of balls 2 and the cage 3 are movably connected, and the number of cages 3 is two, and ...

Embodiment 3

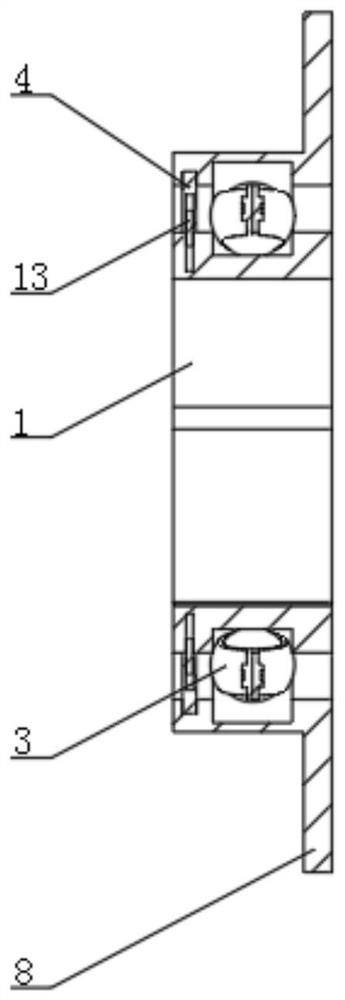

[0031] On the basis of Embodiment 1 and Embodiment 2, as figure 2 , 3, 5, 6, the inner side of the inner ring bearing 15 is provided with a chute 17, and the chute 17 runs through the inner ring bearing 15, the number of the chute 17 is four, and is arranged in a circular array, the slot 6 is embedded On the inner side of the outer ring bearing 1, the sealing ring 4 and the clamping groove 6 are fitted with each other, and the two are movably connected. The inner side of the sealing ring 4 is embedded with a movable half-ring 13, and the number of the movable half-rings 13 is two groups. And arranged in a symmetrical relationship, the sealing ring 4 is used in conjunction with the movable half-ring 13 to play a sealing role, the movable half-ring 13 and the sealing ring 4 are movably connected, and the outer surface of the upper end of the fixing nut 14 is embedded with a slot hole, and the slot hole is The number is two, and they are arranged in a symmetrical relationship. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com