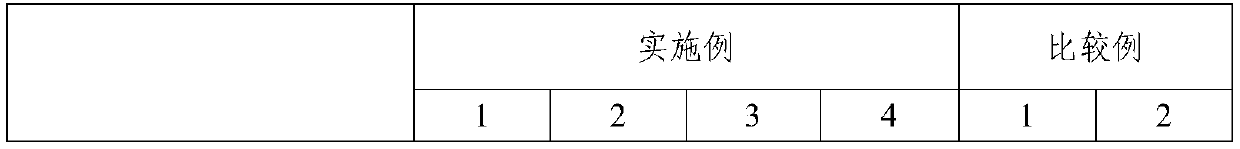

Patents

Literature

55results about How to "Prevent floating phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

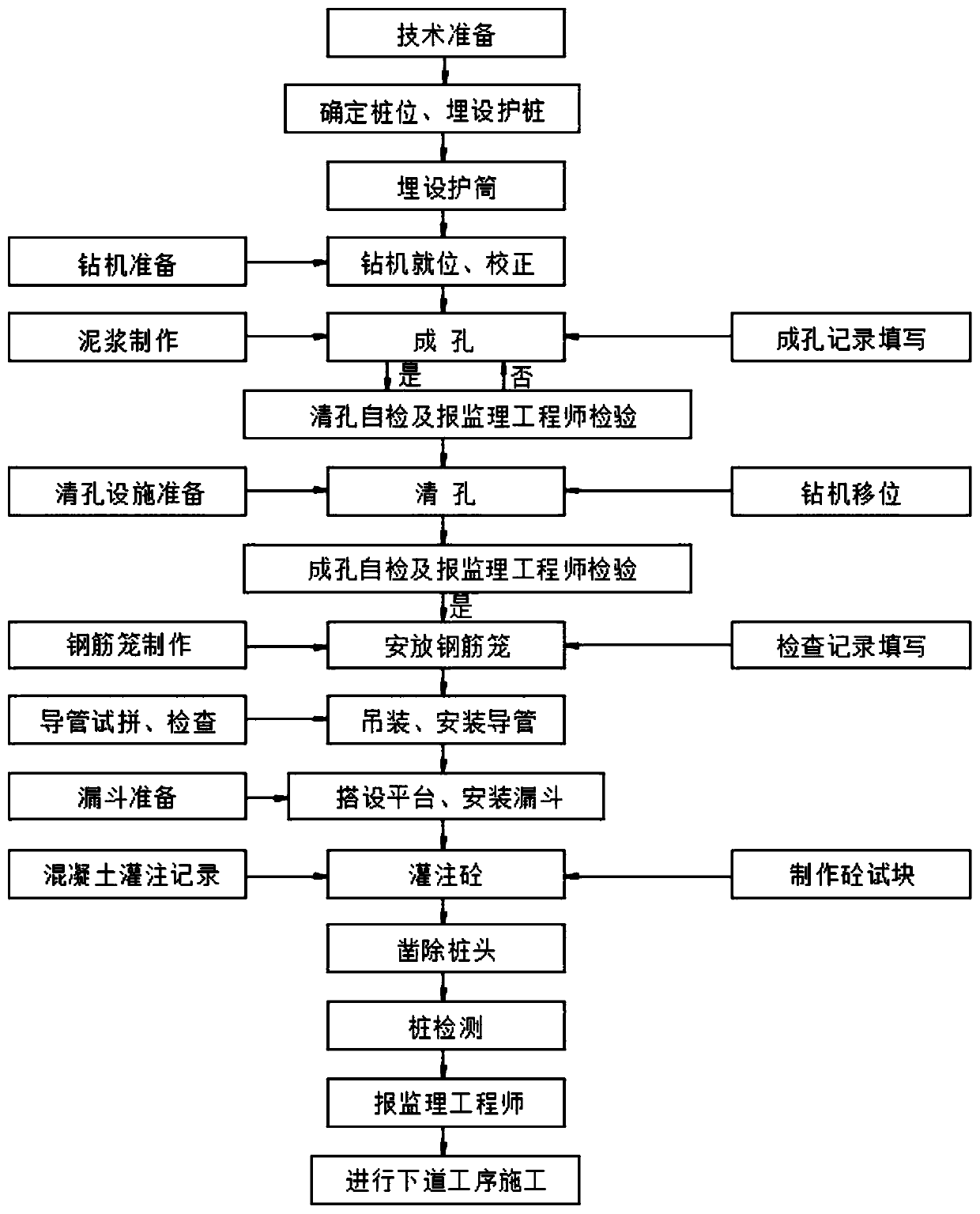

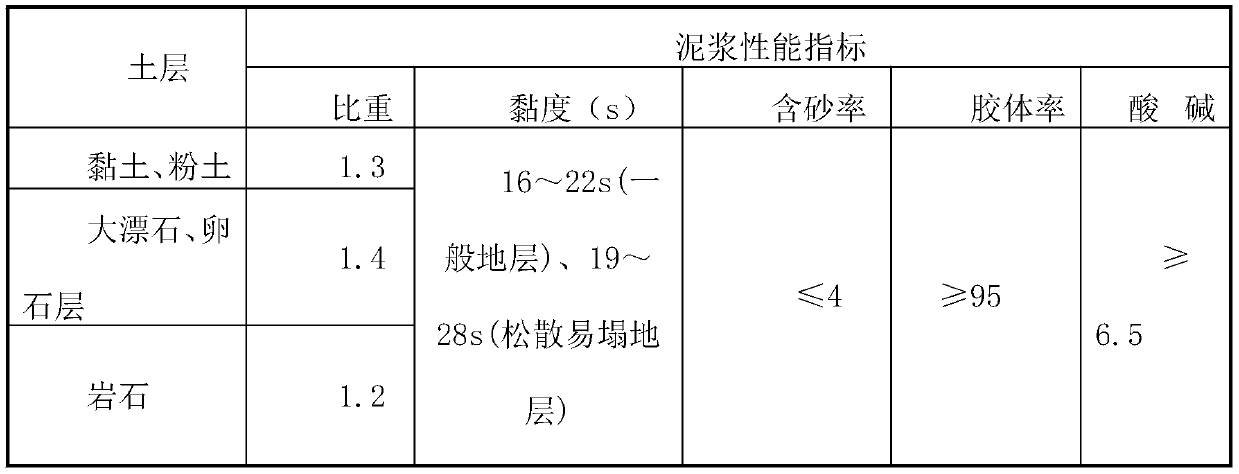

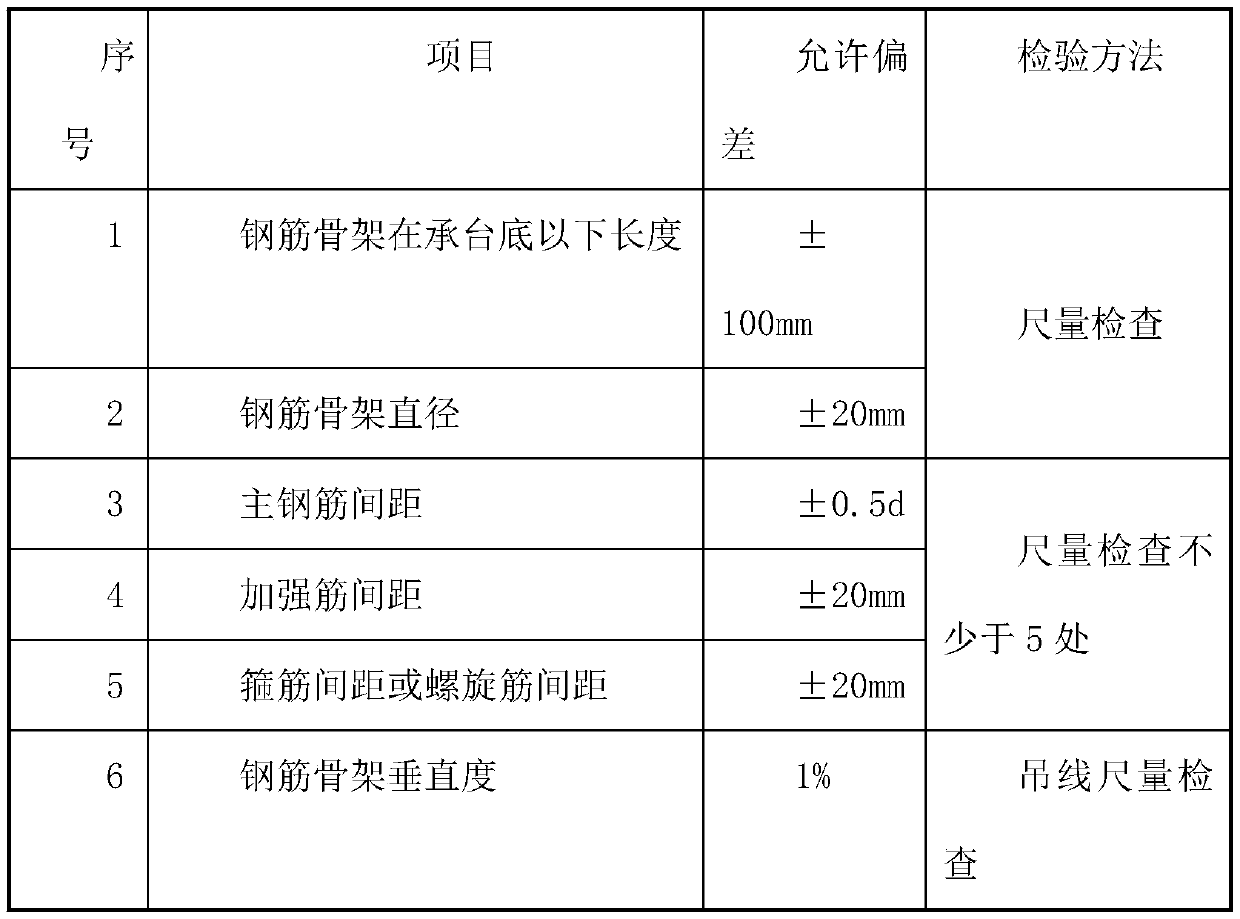

Percussion drill bored pile construction method

InactiveCN110528511AAvoid phenomena that affect the construction progressAvoid water ingressReciprocating drilling machinesFoundation testingSteel barDrilling machines

The invention relates to a percussion drill bored pile construction method and particularly relates to the technical field of percussion drill bored pile construction. The percussion drill bored pileconstruction method concretely comprises the following steps of S1, technical preparation; S2, pile bore positioning measurement wire laying; S3, mud preparation; S4, boring; S5, pore-forming inspection; S6, pore cleaning; S7, machining and placing of a steel bar cage; S8, underwater concrete pouring; and S9, pile foundation detection. According to the percussion drill bored pile construction method, a pedestal is made horizontal when a drilling machine is installed, hoisting pulley edges and the center of a protection barrel need to be on the same straight line, and inspection and correctionare carried out frequently; meanwhile, when a soft-hard stratum inclined interface is encountered in boring, the measure of carrying out flag refilling first and then continuing drilling is taken to rectify a deviation, a repeated filling measure is taken to carry out deviation rectification until pile-forming is completed if the bore deviation phenomenon occurs repeatedly, and the phenomenon thatas uneven stress of a coning impact face, pore position deviation occurs, and the construction speed is influenced is effectively avoided.

Owner:KUNMING RAILWAY CONSTR COMPANY OF CHINA RAILWAY NO 8 ENG GRP

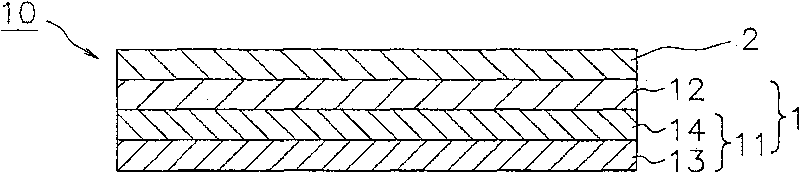

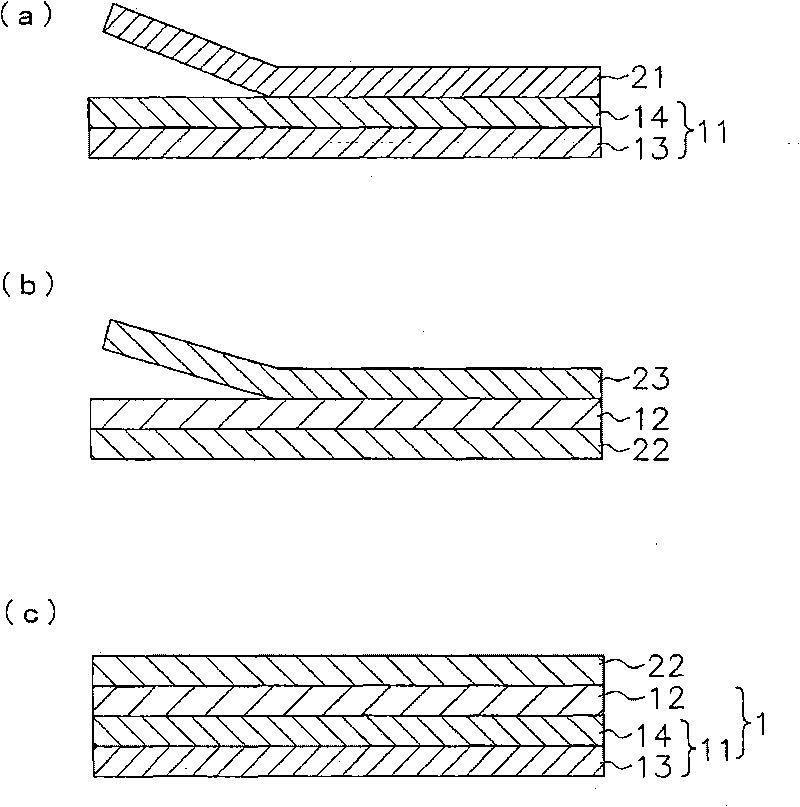

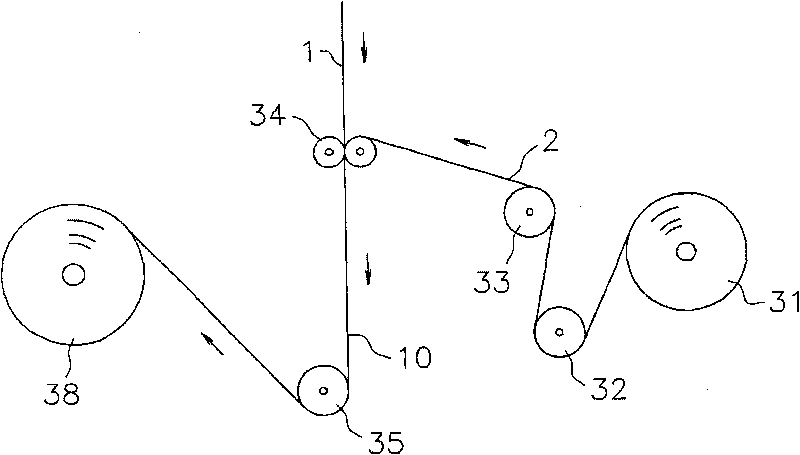

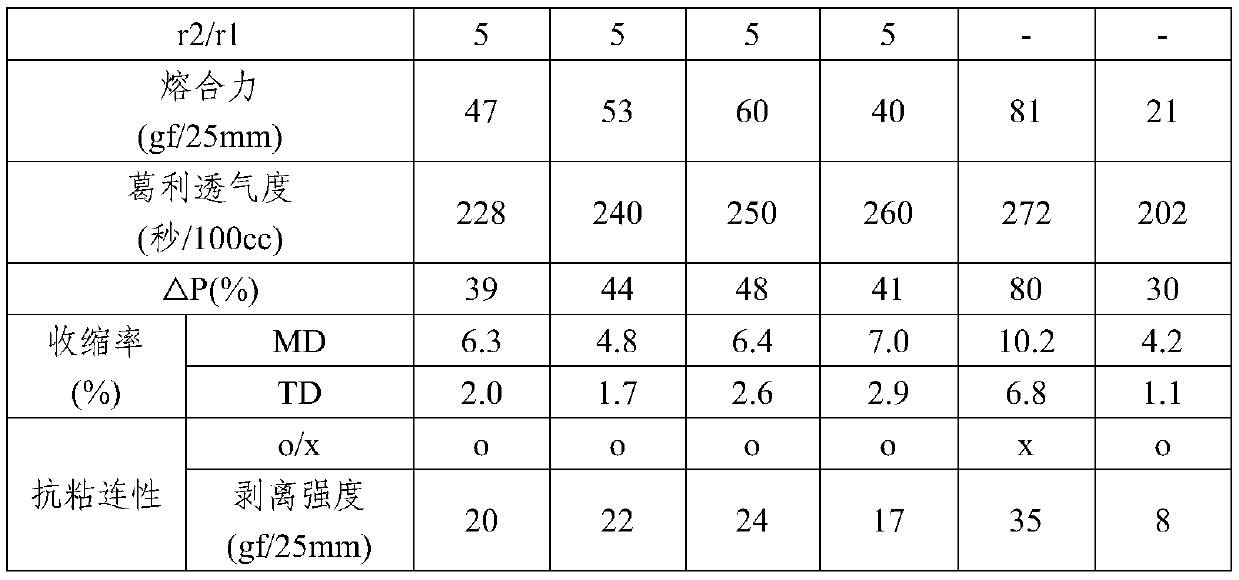

Film for manufacturing semiconductor device and method of manufacturing the same

InactiveCN101752217APrevent floating phenomenonPrevent interfacial peelingLamination ancillary operationsLayered product treatmentEngineeringSemiconductor

A present invention relates to a film for manufacturing a semiconductor device in which a cover film is pasted onto a laminated film, wherein the shrinkage in the longitudinal direction and in the lateral direction in the laminated film after peeling the cover film and leaving for 24 hours at a temperature of 23+-2 DEG C. is in a range of 0 to 2% compared to the laminated film before pasting of the cover film.

Owner:NITTO DENKO CORP

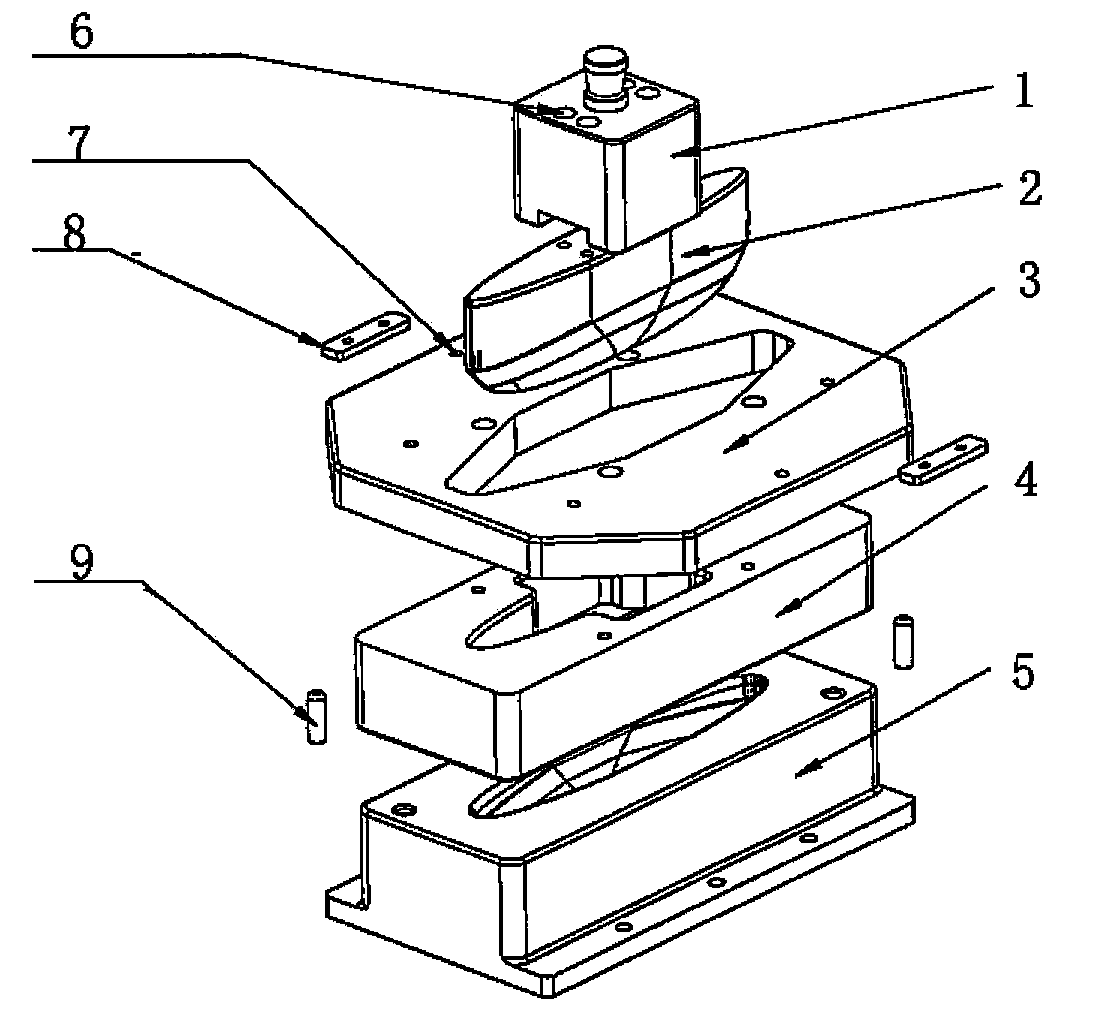

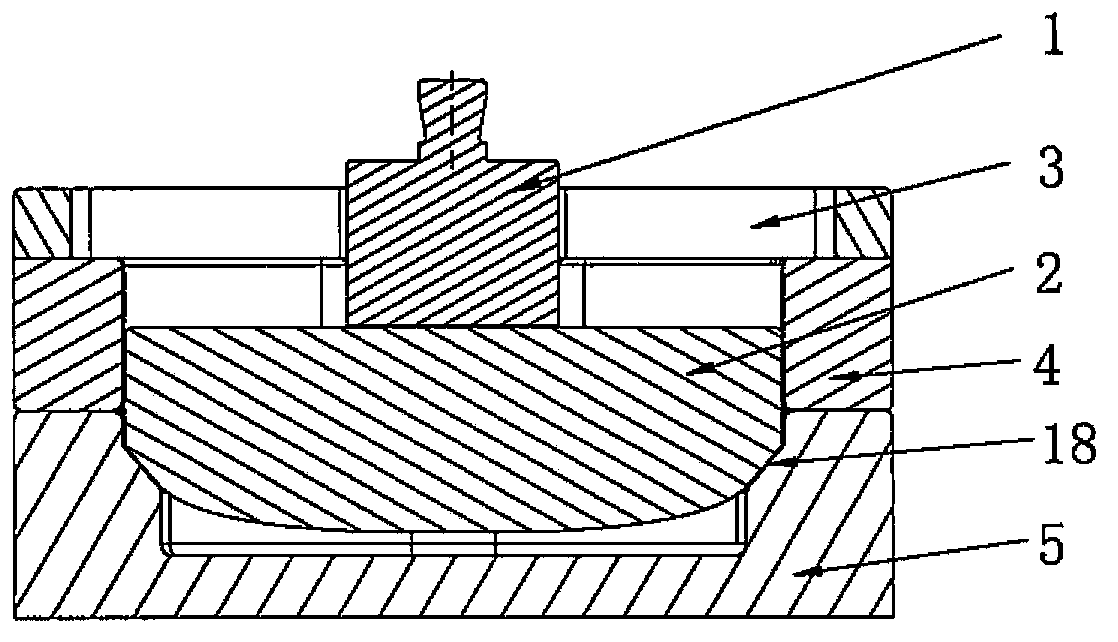

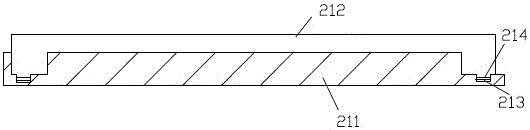

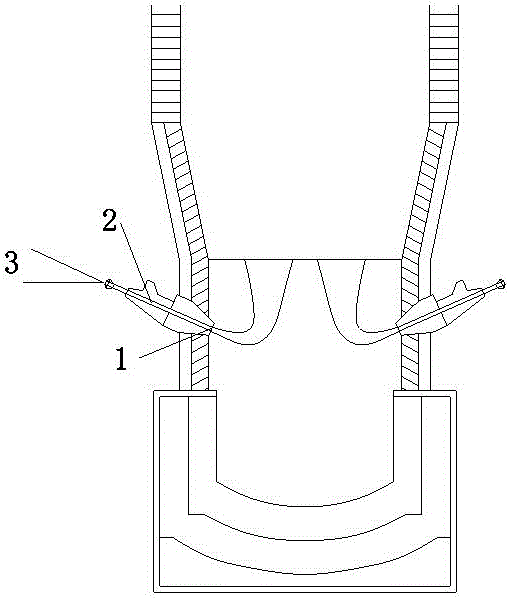

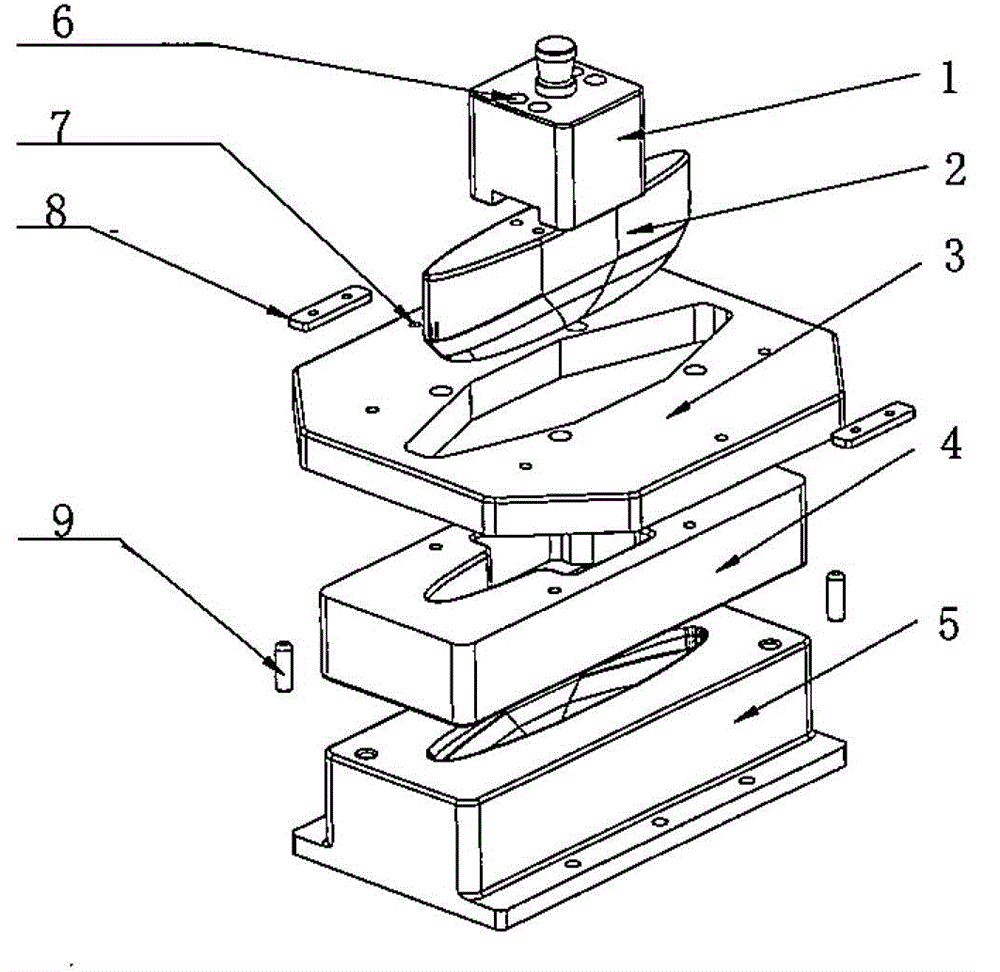

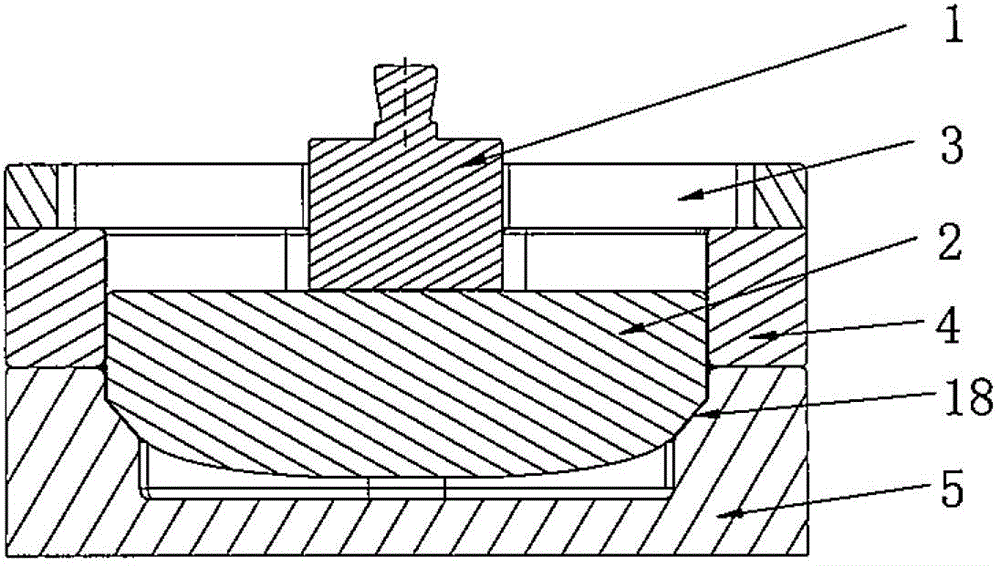

Forming die of skin part for airplane

ActiveCN103464561ARaise the forming limitReduce the number of deep drawingShaping toolsAirplaneMaterials science

The invention relates to a forming die of a skin part for an airplane. The forming die comprises a compression block, a male die, a female die, a binder ring and a pressing plate, wherein the male die comprises a straight wall part and a forming part; the female die is provided with a cavity for holding billets and liquid; the binder ring comprises an upper binder ring and a lower binder ring; the lower binder ring can be slidably located on the female die in the longitudinal direction, and is provided with a second penetrating hollow part adapt to a lower straight wall part; the upper binder ring can be detachably fixed on the lower binder ring, and is provided with a first up-and-down penetrating hollow part; the upper binder ring is detachably connected with a second pressurizing source, so that the compression block and the male die sequentially penetrate through the first hollow part and the second hollow part under the action of a first pressurizing source, and when the forming part of the male die is used for forming the billets in the cavity of the female die, the second pressurizing source presses the upper binder ring and the lower binder ring on the female die. According to the forming die of the skin part for the airplane, the resilience after a part is formed is effectively reduced, and the forming accuracy and the surface quality are improved.

Owner:SHANGHAI AIRCRAFT MFG +1

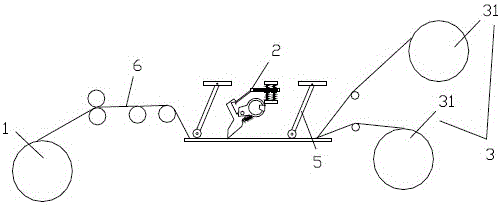

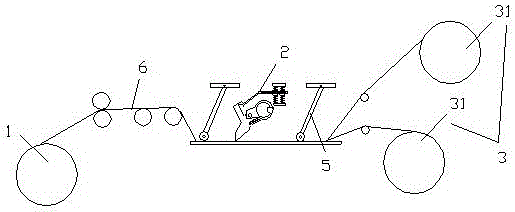

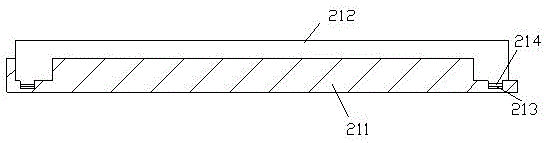

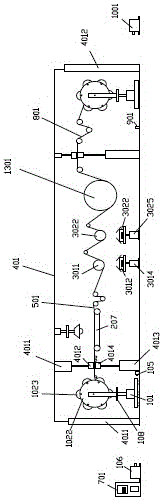

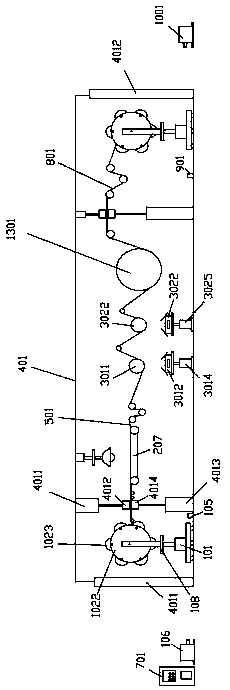

Metallized thin film dividing and cutting machine

ActiveCN106541433AIncrease flexibilityIncrease diversityMetal working apparatusEngineeringScrew thread

The invention discloses a metallized thin film dividing and cutting machine, which comprises a feeding mechanism, a dividing and cutting mechanism and a film winding mechanism. The feeding mechanism, the dividing and cutting mechanism and the film winding mechanism are sequentially arranged from front to back according to a technological process; the dividing and cutting mechanism comprises a dividing and cutting cutter assembly and a movable positioning mechanism; a thin film is transferred between the dividing and cutting cutter assembly and the movable positioning mechanism; film pressing mechanisms are arranged between the feeding mechanism and the dividing and cutting mechanism as well as between the dividing and cutting mechanism and the film winding mechanism respectively; each film pressing mechanism comprises a rocking bar; the upper ends of the rocking bars are hinged to a rack; the lower ends of the rocking bars extend to positions above adjusting plates and can make contact with the thin film; the film winding mechanism comprises a film winding shaft and multiple groups of film winding barrels; the outer diameters of the multiple groups of film winding barrels are different; and any two film winding barrels can be in screw-thread fit. The metallized thin film dividing and cutting machine provided by the invention has the advantages of convenience in operation, capability of effectively preventing relative sliding between cutting heads and shafts, adjustment flexibility and diversity in thin film dividing and cutting breadth, and precision in rotation angles of dividing and cutting cutters.

Owner:TONGLING QILI ELECTRONICS MATERIALS

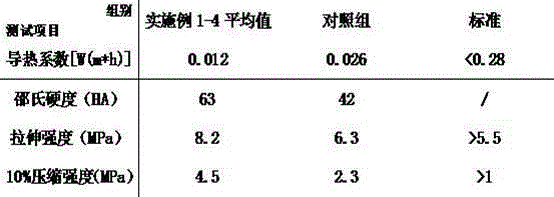

High-hardness impact-resisting heat-insulation foaling plastic

The invention discloses high-hardness impact-resisting heat-insulation foaling plastic. The high-hardness impact-resisting heat-insulation foaling plastic is prepared from, by weight, 20-25 parts of polystyrene resin, 40-55 parts of polyurethane resin, 20-25 parts of phenolic resin, 10-15 parts of urea formaldehyde resin, 4-7 parts of diethylaminopropylamine DEAPA, 2-5 parts of azobisformamide AC, 0.9-1.2 parts of polydimethylsiloxane-polyoxyalkylene copolymer, 1-4 parts of talcum powder, 0.3-0.6 part of quartz powder, 1.4-1.7 parts of hollow microspheres, 1-4 parts of bentonite, 20-25 parts of diatomite, 10-13 parts of calcium carbonate, 5-8 parts of polyethylene-octene copolymer elastomer and 12-16 parts of glass fiber, wherein the polydimethylsiloxane-polyoxyalkylene copolymer is obtained by polydimethylsiloxane and polyoxyalkylene through blending modification, and the polyethylene-octene copolymer elastomer is obtained by polyethylene and octene through blending modification. Air bubbles in the high-hardness impact-resisting heat-insulation foaling plastic are even, the heat conductivity coefficient is reduced, the heat-insulation performance is improved, and the hardness and impact resistance are further greatly improved.

Owner:ZIBO KUAKE MEDICINE TECH

Bath smelting side-blowing jet flow gush type enhanced stirring method

InactiveCN106544526ARealize large-scaleImprove melt strengthRotary drum furnacesCrucible furnacesMelting tankHearth

The invention relates to a bath smelting side-blowing jet flow gush type enhanced stirring method, belonging to the technical field of metallurgy. Firstly a nozzle is inclined to the bottom of a hearth with an inclination angle of 5 to 40 degrees; by reducing the diameter of the nozzle 1 to 1.0 to 3.0cm, and setting wind pressure in an air flue communicated with the nozzle to 0.2 to 0.4MPa, and enabling oxygen-rich air to blow into a bath from the side in a jet flow way, thus generating bath stirring like gush. The body of a side-blowing furnace can be enlarged to increase an effective smelting area, thus further improving smelting intensity of the side-blowing furnace, generating a scale effect, and reducing the unit production cost of the side-blowing furnace.

Owner:KUNMING UNIV OF SCI & TECH

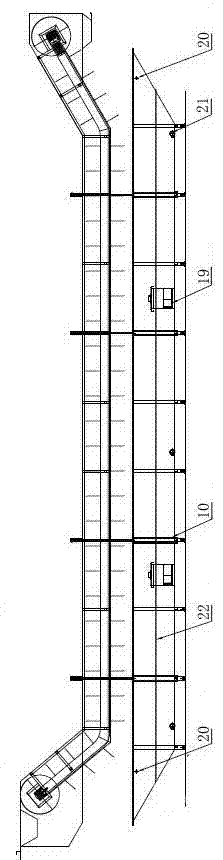

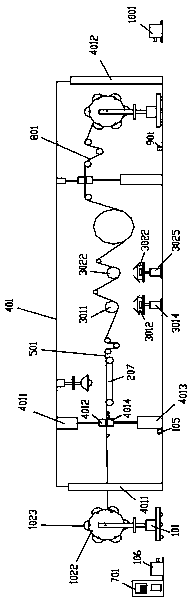

Metallized film breadth linearly adjustable type splitting machine and unit thereof

InactiveCN106514735AIncrease flexibilityIncrease diversityMetal working apparatusArticle deliveryTool bitThin membrane

The invention discloses a metallized film breadth linearly adjustable type splitting machine. the metallized film breadth linearly adjustable type splitting machine comprises a feeding mechanism, a splitting mechanism and a film rolling mechanism which are arranged sequentially from front to back according to the technological process. The splitting mechanism comprises a splitting cutter assembly and a movable locating mechanism. a film is conveyed between the splitting cutter assembly and the movable locating mechanism. a film pressing mechanism is arranged between the feeding mechanism and the splitting mechanism, and a film pressing mechanism is arranged between the splitting mechanism and the film rolling mechanism. each film pressing mechanism comprises a rocker. The upper end of the rocker is hinged to a rack. The lower end of the rocker extends to the upper portion of an adjusting plate and can make contact with the film. the metallized film breadth linearly adjustable type splitting machine has the advantages that operation is convenient, relative sliding between a cutter head and a shaft is prevented effectively, adjustment of the film splitting breadth is flexible and various, and the rotation angle of a splitting cutter is precise.

Owner:TONGLING QILI ELECTRONICS MATERIALS

Emulsification stabilizer and cereal dietary fiber beverage containing same

InactiveCN103371309AInhibition of precipitationPrevent water precipitationFood preparationNutrientDietary fibre

The invention relates to an emulsification stabilizer and a cereal dietary fiber beverage containing the same. The emulsification stabilizer comprises an emulsifier, hydrophilic gel and emulsifying salt. The novel stabilizer is capable of effectively suspending starch retrogradation particles in the cereal dietary fiber beverage, effectively inhibiting the sediment phenomenon of the cereal dietary fiber beverage, preventing the drainage phenomenon caused by common starch retrogradation in the cereal dietary fiber beverage, and remarkably covering delayed bitterness generated by polypeptides. The prepared cereal dietary fiber beverage has the characteristics of a stable state, a smooth mouth feel, capability of effectively supplementing dietary fibers of a human body, and easiness in absorption of nutrients.

Owner:DSM IP ASSETS BV

Pasteurized and heat-treated flavored fermented milk and preparation method thereof

InactiveCN106172757APromote growthPromote digestion and absorptionMilk preparationLactobacillusNutritive valuesRoom temperature

The invention relates to the technical field of foods and in particular relates to pasteurized and heat-treated flavored fermented milk and a preparation method thereof. The pasteurized and heat-treated flavored fermented milk is prepared from the following raw materials in parts by weight: 30 to 70 parts of raw milk, 3 to 10 parts of whole milk powder, 5 to 15 parts of a sweetener, 0.5 to 1.0 part of a stabilizer, 0.2 to 0.4 part of lactic acid, 0.008 to 0.012 part of fermentation strain and 15 to 50 parts of water. The preparation method of the pasteurized and heat-treated flavored fermented milk comprises the steps of material mixing, first time of homogenization and sterilization, fermentation, blending, and second time of homogenization and sterilization. The fermented milk provided by the invention has a unique taste, is convenient to drink and is high in nutritional value; the pasteurized and heat-treated flavored fermented milk is preserved at a room temperature, has a long guarantee period and is convenient to transport and store. According to the preparation method, two times of sterilization and homogenization processes are adopted and the fermented milk with a pasteurization effect is obtained; the method is simple and convenient, is suitable for industrial production and is low in equipment cost and low in production cost.

Owner:河南花花牛乳业集团股份有限公司

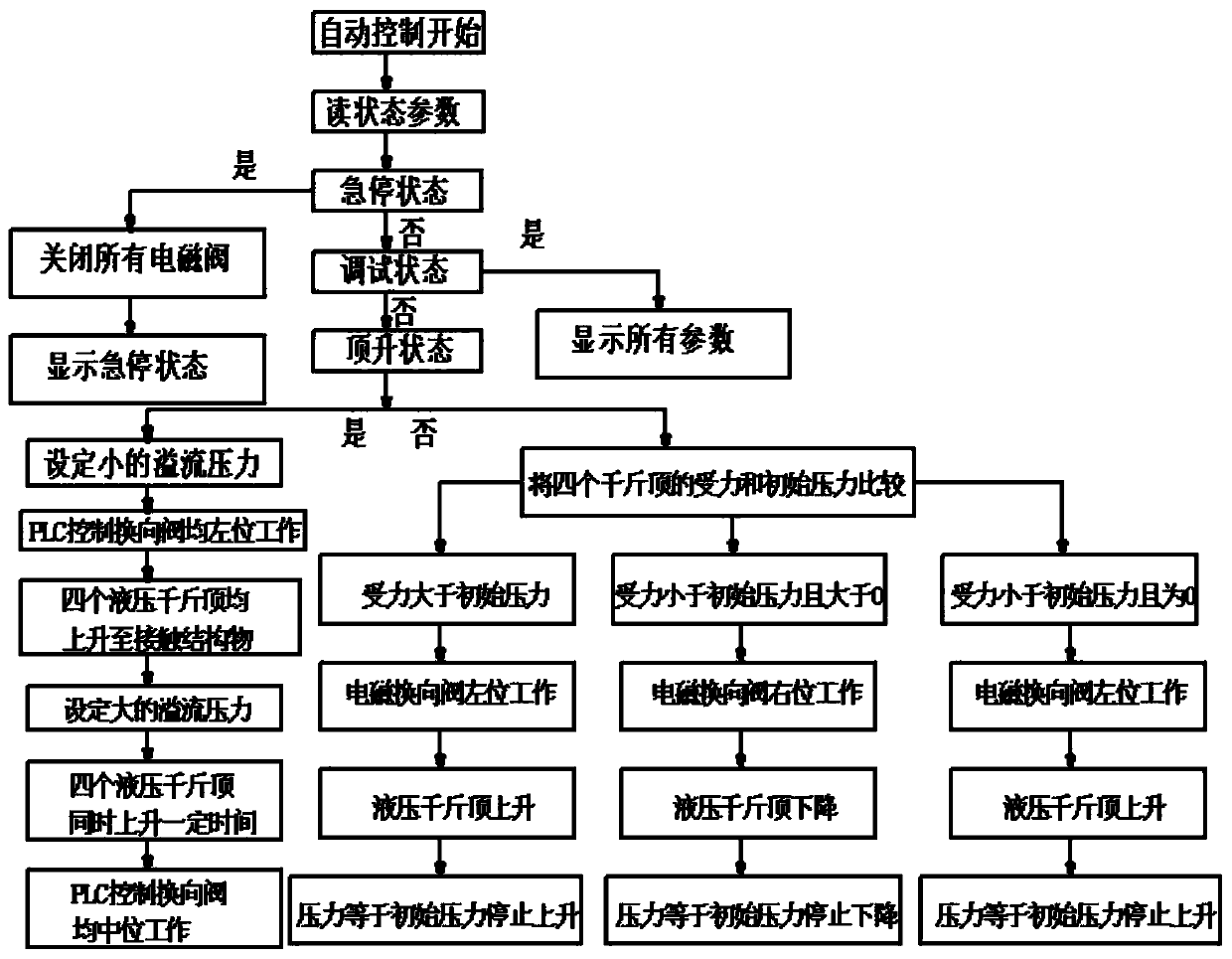

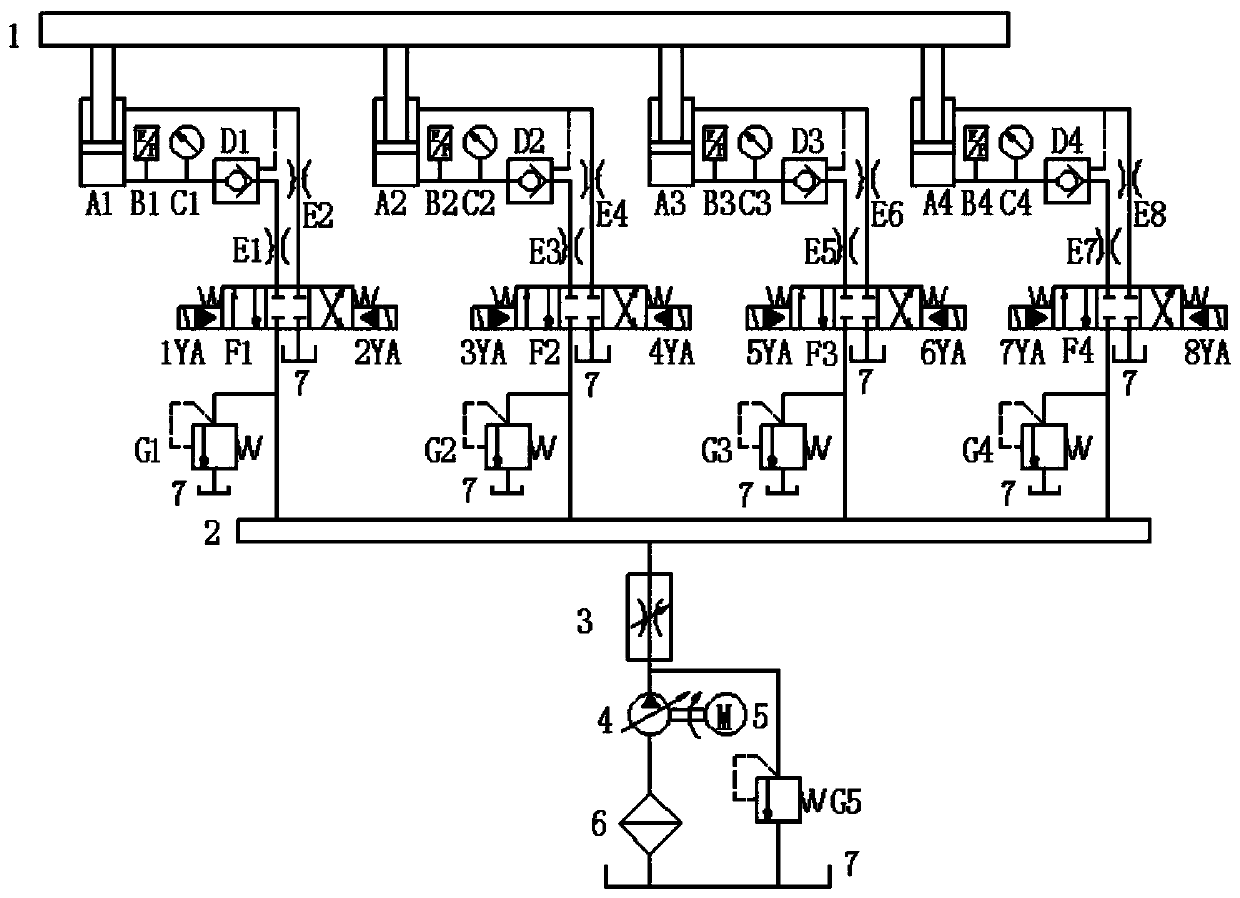

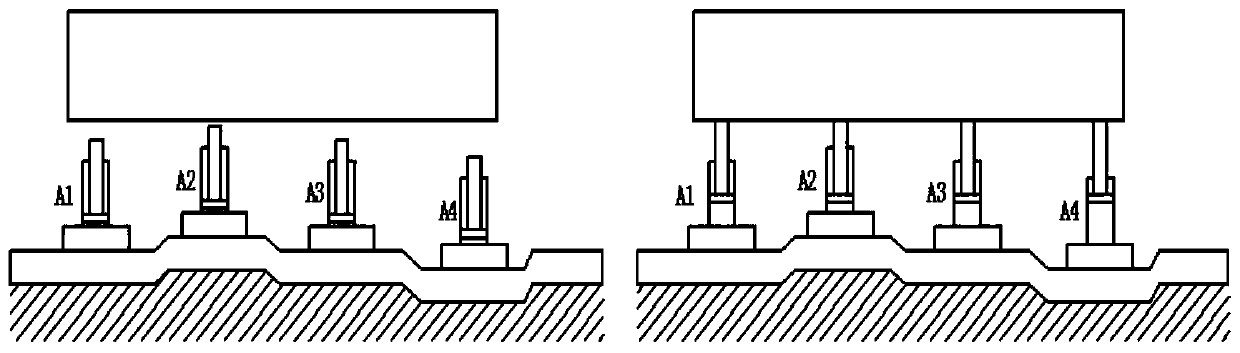

Active control method for slippage shipment process of large marine structure

InactiveCN110436372AAvoid overall overturningForce coordinationLifting devicesFluid-pressure actuator componentsEngineeringMechanical engineering

The invention relates to an active control method for a slippage shipment process of a large marine structure. The method can be used for solving the problem of adjusting the wharf stress in the slippage displacement process and in the shipment process at the same time. The lifting of each jack pile leg can be independently controlled through lifting adjustment of each hydraulic jack pile leg; thestress of each jack pile leg can be coordinated through carrying out lifting adjustment on all jack pile legs as needed, so that the sliding displacement process and the loading process of the structure are controlled to be smoothly carried out; and meanwhile, the phenomenon that the jack pile legs are suspended is prevented, and the problem that the structure is overturned due to the fact that certain jack pile legs damage a wharf due to too large stress is solved.

Owner:TIANJIN UNIV MARINE TECH RES INST

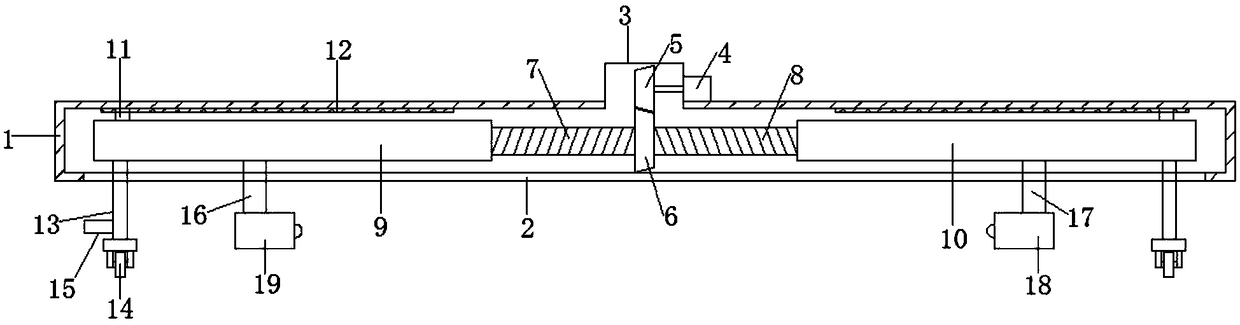

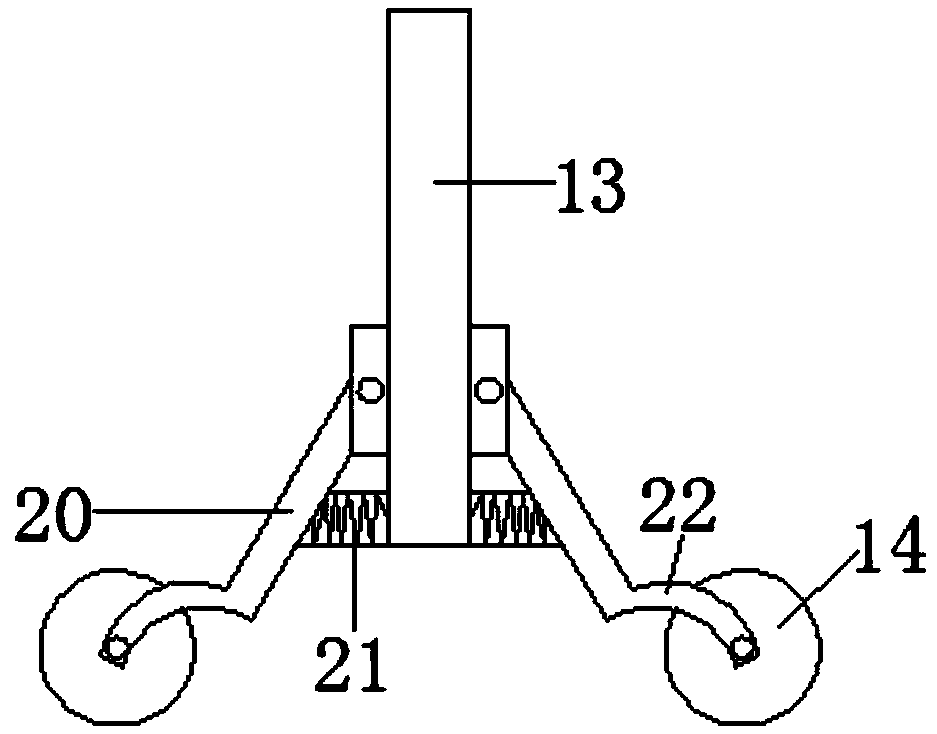

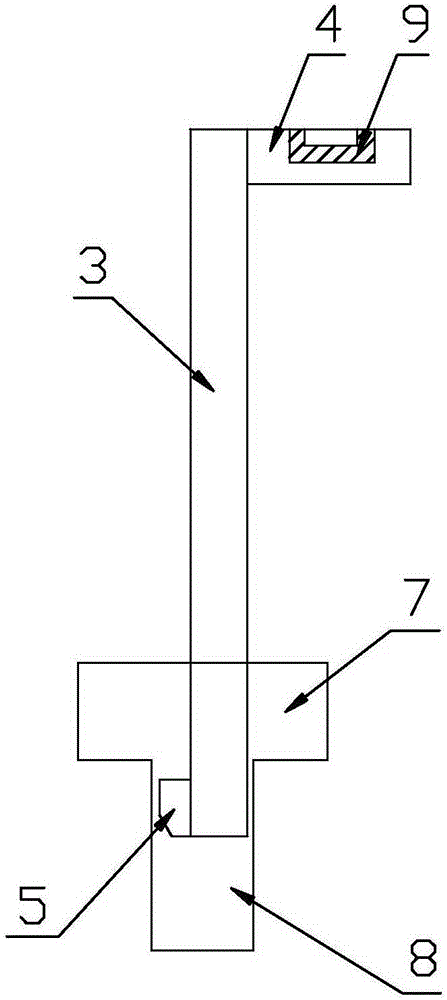

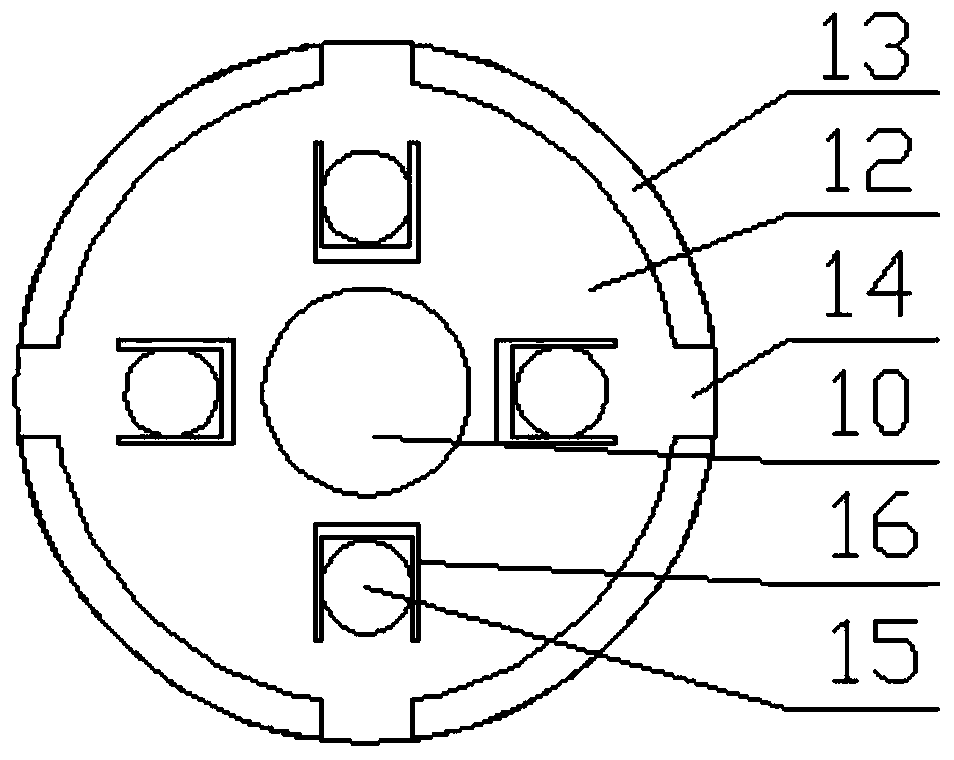

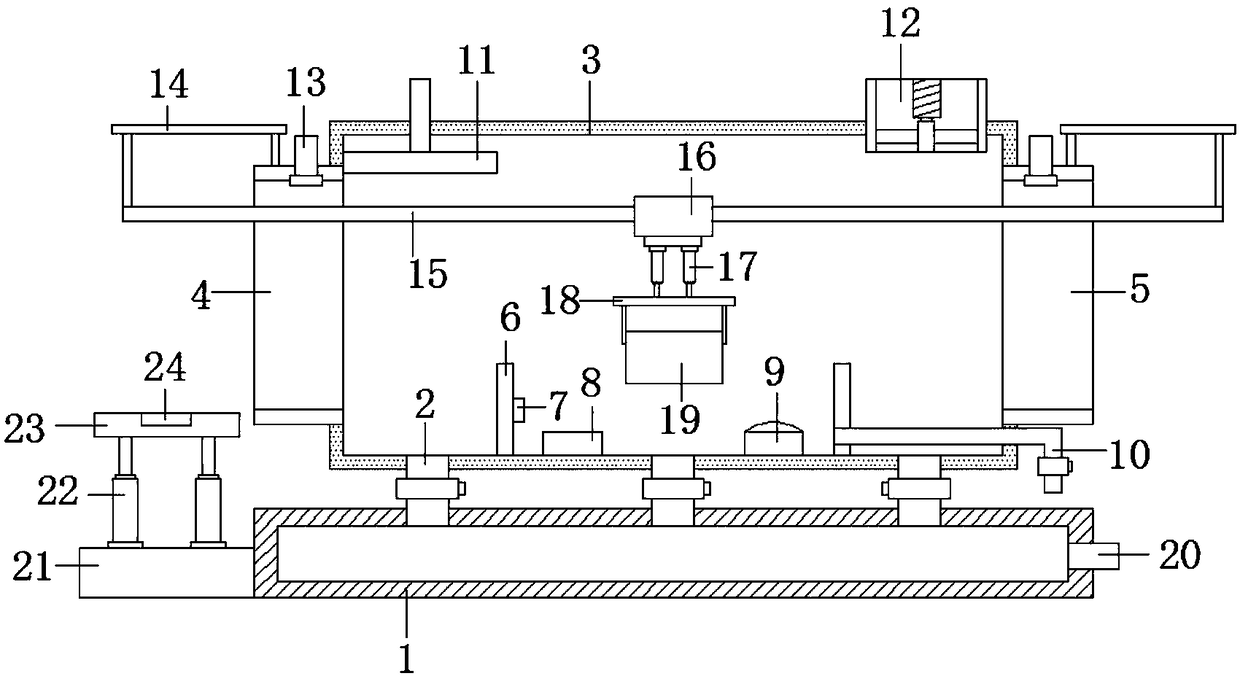

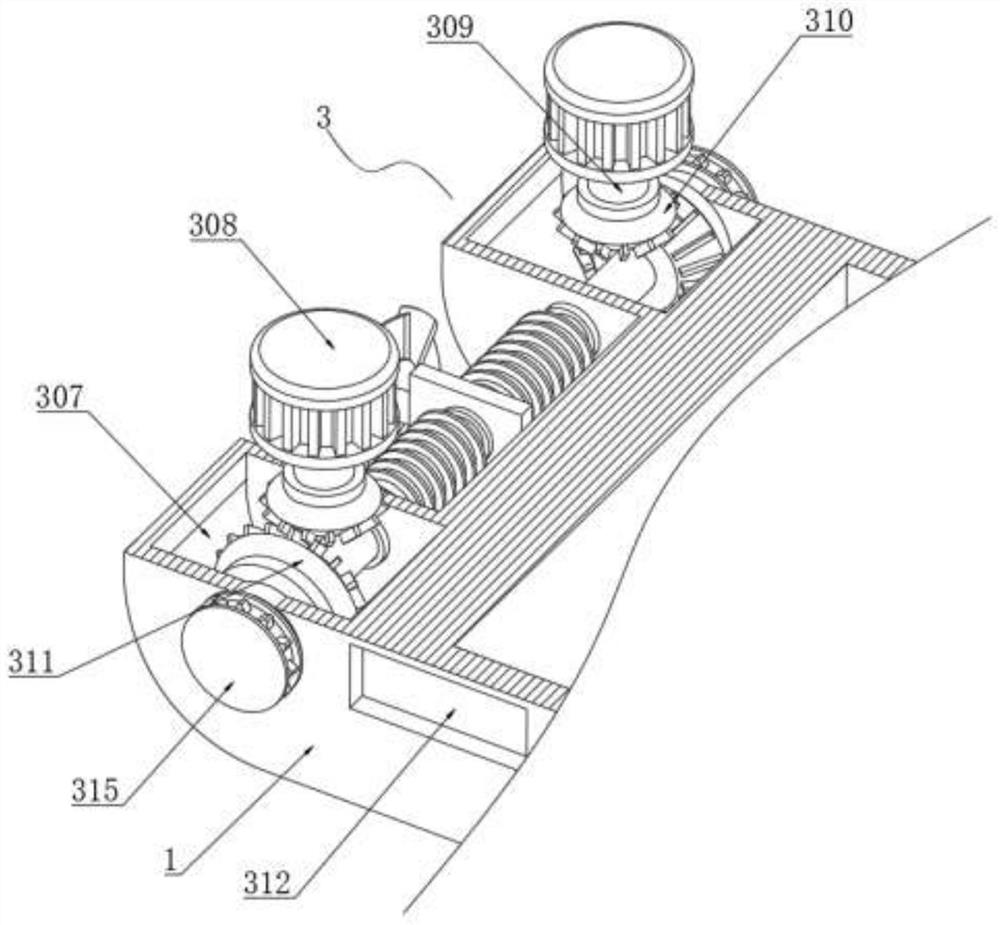

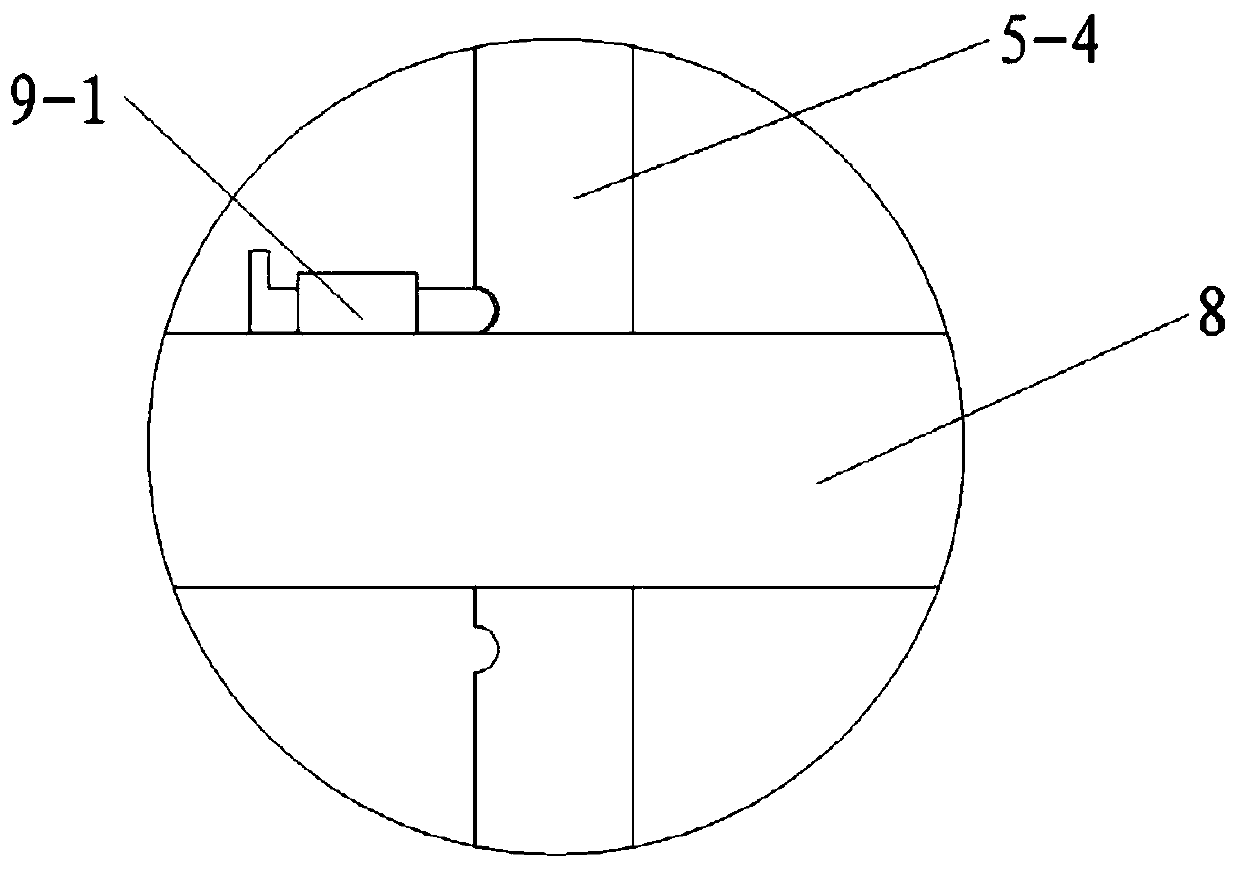

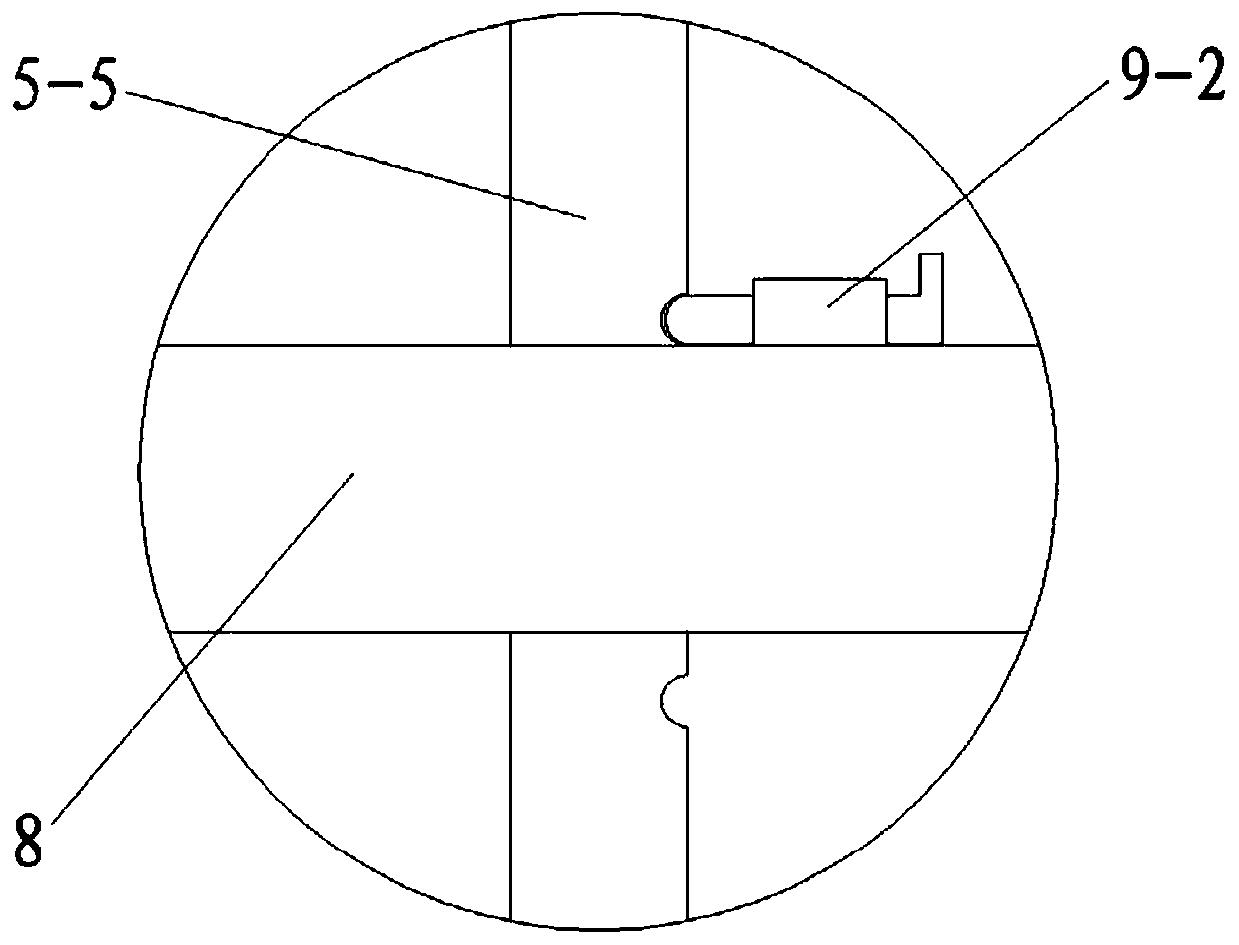

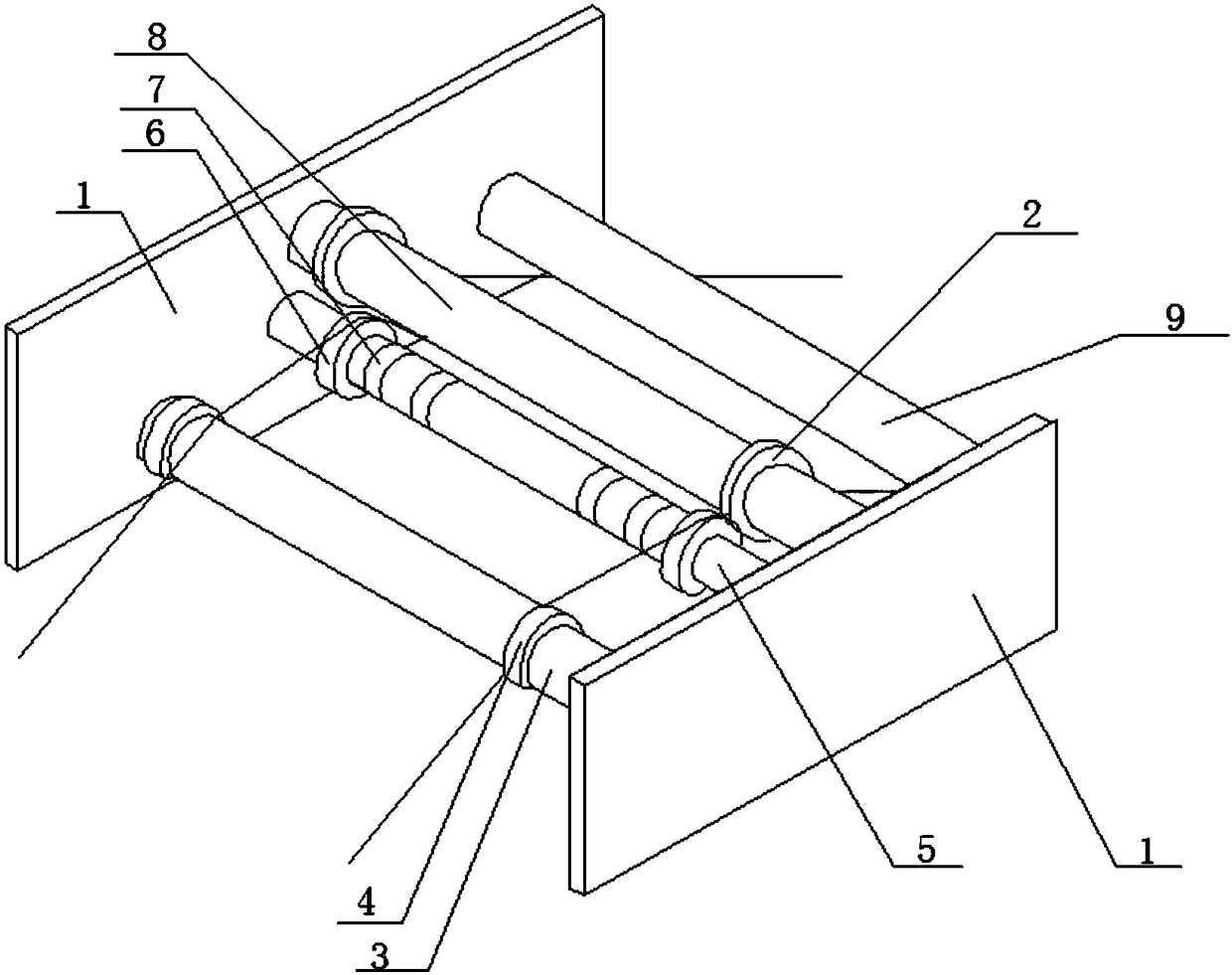

TOFD automatic scanning device

PendingCN108956763ARealize distance adjustmentRealize linkageAnalysing solids using sonic/ultrasonic/infrasonic wavesDrive shaftEngineering

Belonging to the technical field of TOFD detection equipment, the invention specifically discloses a TOFD automatic scanning device. The device comprises a main beam with a hollow inner structure, a movable groove is disposed at the bottom of the main beam, a gearbox is mounted at a top central position of the main beam, the gearbox is communicated with the inner cavity of the main beam, and an active conical gear is longitudinally arranged at a central position of the gearbox's inner cavity, a motor is installed on the right side of the gearbox, the left side power output end of the motor isfixedly connected to the right side of the active conical gear through a transmission shaft, the bottom of the active conical gear is in engaged connection with a driven conical gear, rotation of themotor can realize adjustment of the distance between probes and rollers, and the probes and rollers can realize linkage, thus improving the detection efficiency. And through arrangement of arc-shapedbrackets and springs, the rollers can cling to pipe walls, thus preventing dangling phenomenon of the rollers, and improving the image definition.

Owner:菏泽市产品检验检测研究院

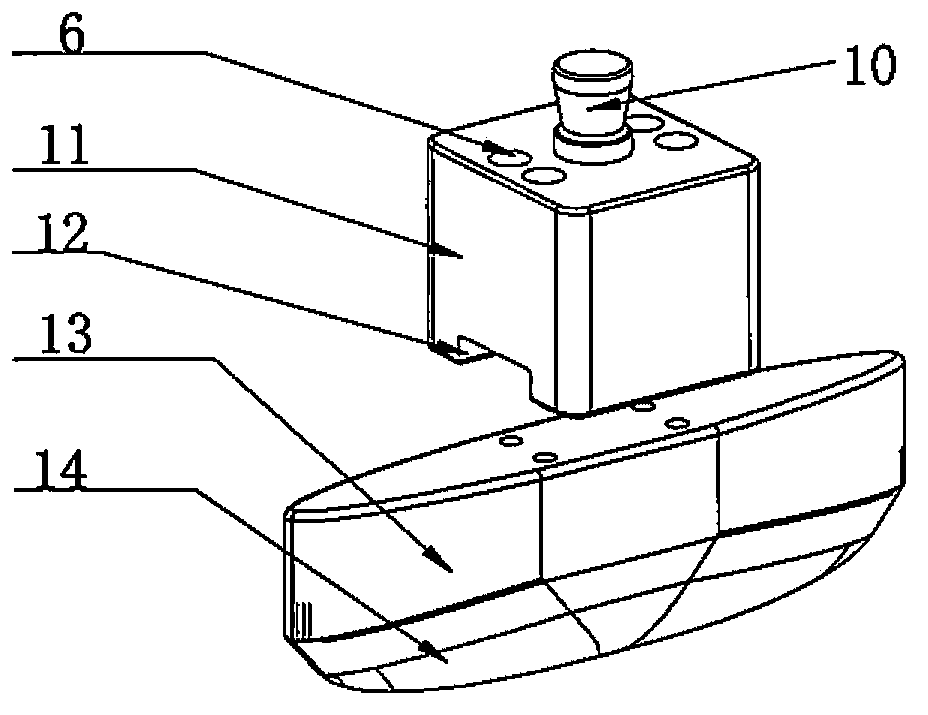

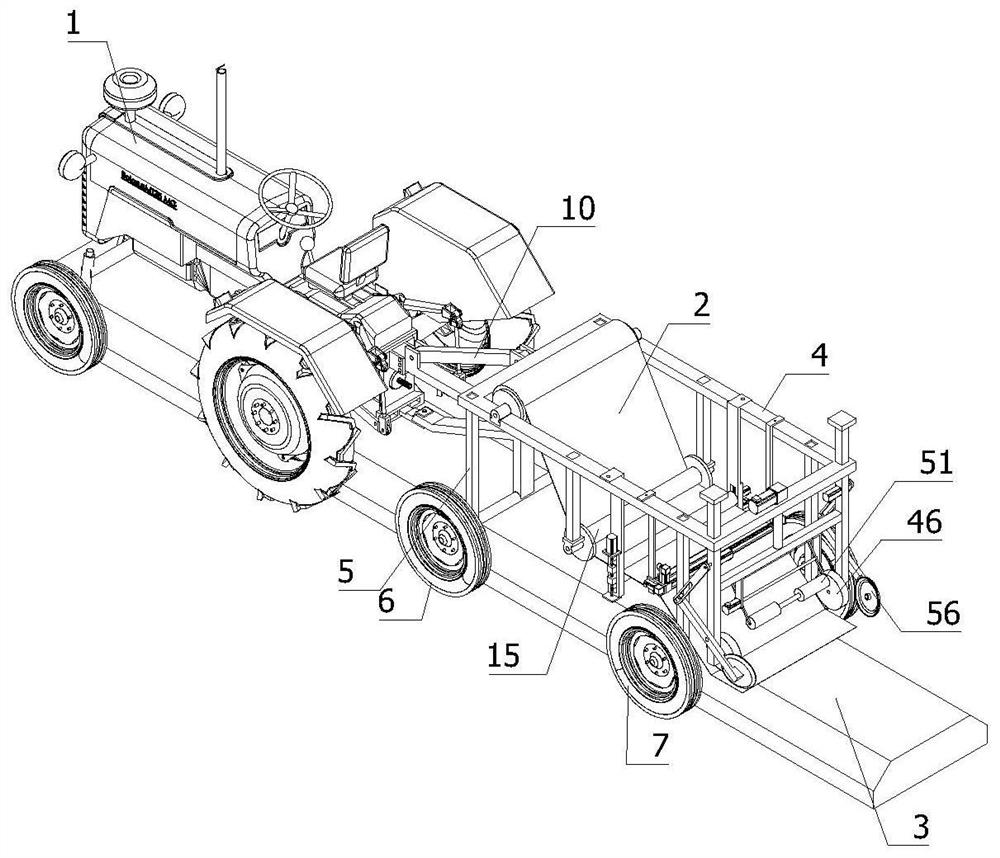

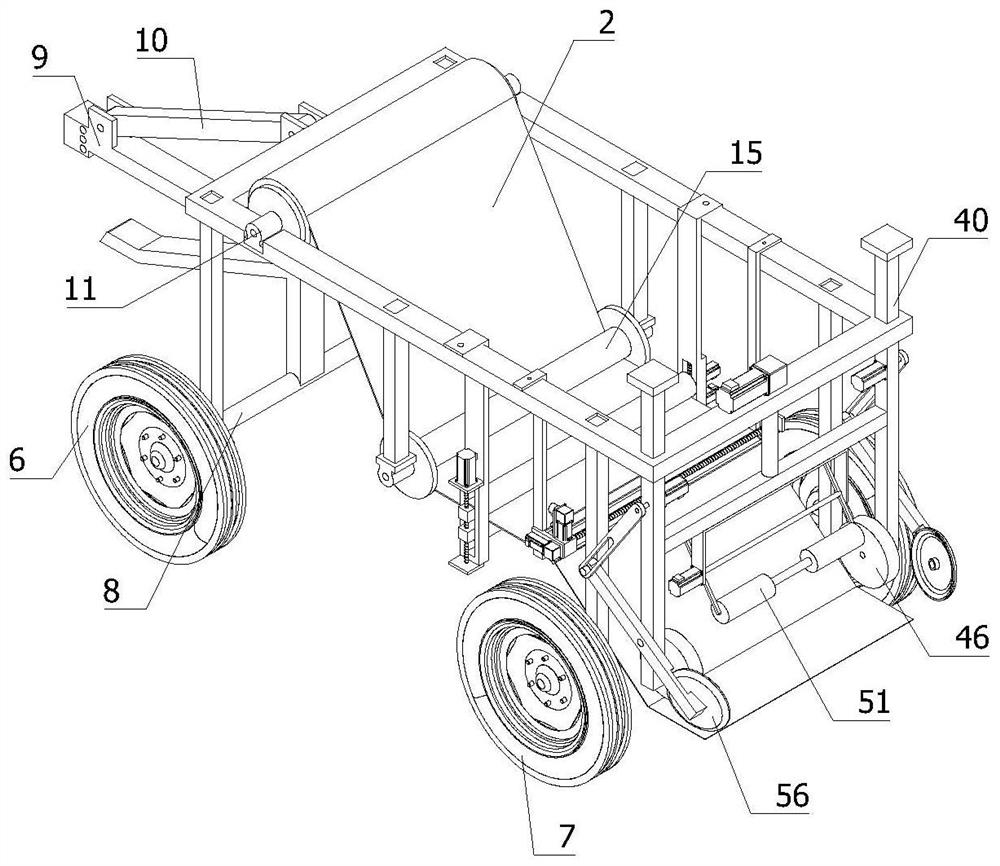

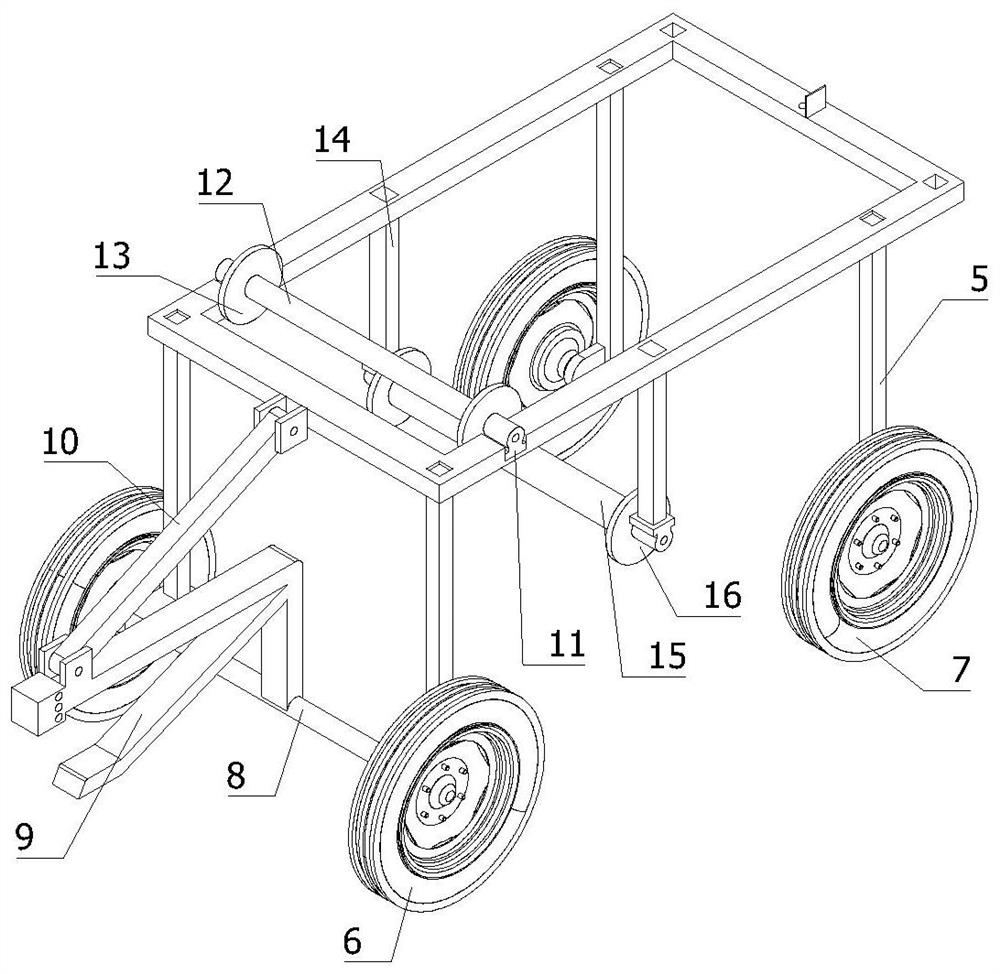

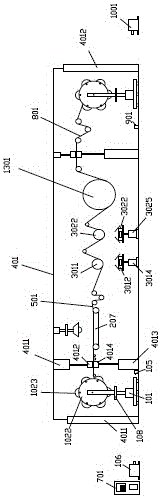

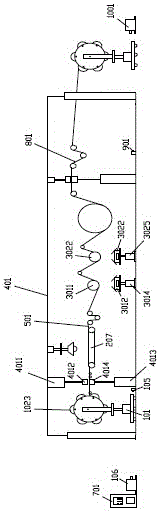

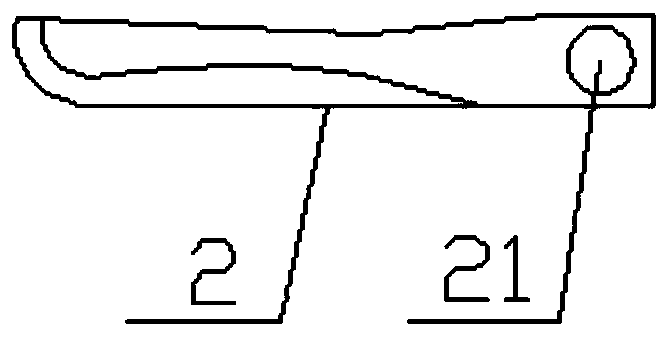

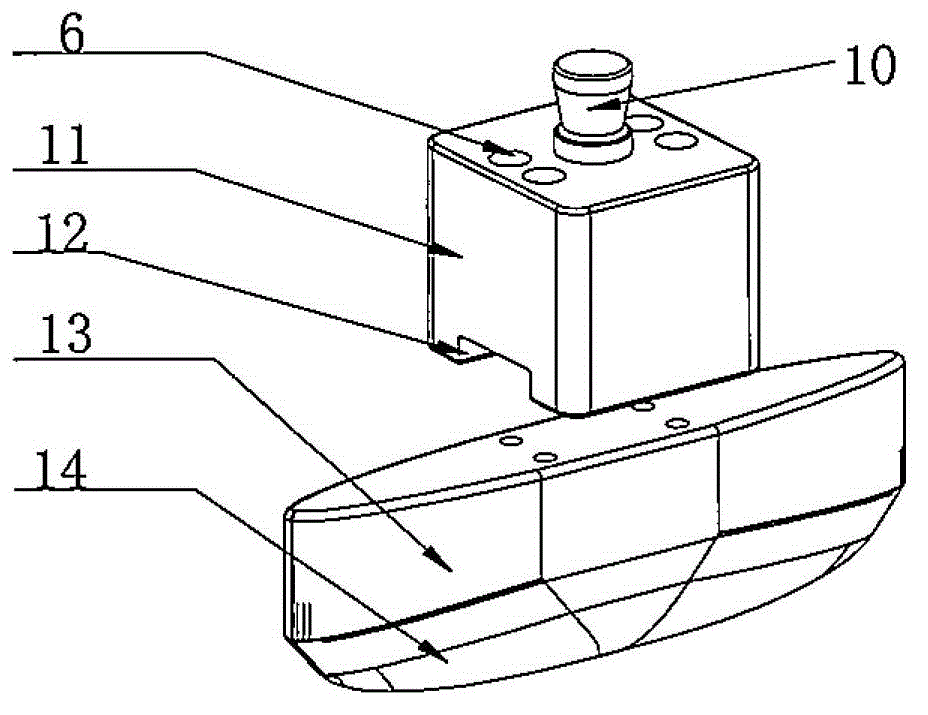

Agricultural soil falling and edge sealing type land mulch applicator

InactiveCN112930987AEasy to coverPrevent floating phenomenonMetal working apparatusPlant protective coveringsAgricultural engineeringFilm-out

The invention relates to the field of agricultural production, in particular to an agricultural soil falling and edge sealing type land mulch applicator. The agricultural soil falling and edge sealing type land mulch applicator comprises a tractor, a dragging assembly, a film rolling assembly, a cutting-off assembly, an output assembly, an edge pressing assembly, a top pressing assembly and a soil shifting assembly, wherein the dragging assembly is used for installing all film mulching devices, the film rolling assembly is used for placing films, the cutting-off assembly is used for cutting off the films after land film mulching is completed, the output assembly is used for leading the cut-off films out, the output assembly is further located between the film rolling assembly and the cutting-off assembly, the edge pressing assembly is used for pressing the side edges of the films to land and arranged at the tail end of the dragging assembly, the top pressing assembly is used for pressing the tops of the films to the land and arranged on the edge pressing assembly, and the soil shifting assembly is arranged on the edge pressing assembly, is used for shifting soil around the land to the side edges of the films so as to be covered, and is arranged on the edge pressing assembly. According to the agricultural soil falling and edge sealing type land mulch applicator, the problem that time and labor are wasted and the film mulching efficiency is low due to the fact that land film mulching is carried out manually in the prior art is solved, manual labor is reduced, and the land film mulching efficiency is improved.

Owner:湛宗平

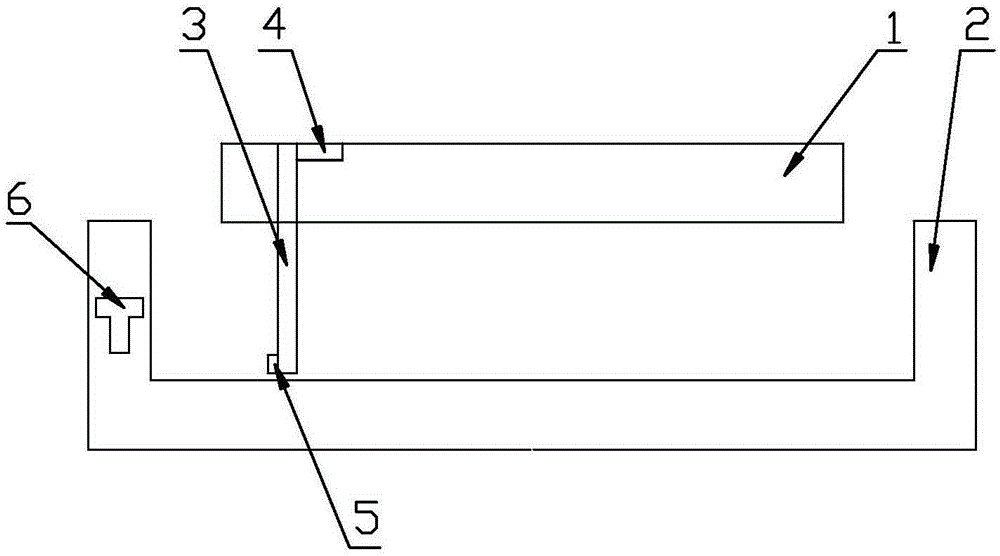

Anti-floating well lid

ActiveCN105178361AEasy to openWill not affect levelingArtificial islandsUnderwater structuresEngineeringMechanical engineering

The invention discloses an anti-floating well lid. The well lid comprises a lid body and a base, wherein the base is arranged in a bottom well mouth; the lid body is a circular structure fitted with the base; the lid body is connected on the base by virtue of an anti-floating structure; the anti-floating structure comprises a pin, a pin head and a pin bottom; the upper part of the pin is vertically and movably connected on the side edge of the lid body; a groove is formed in the lid body; the pin head is clamped in the groove; an opening which is a T-shaped structure is formed in the base; the opening comprises an upper part and a lower part; the pin is vertically arranged in the opening; and the pin bottom is clamped in the lower part of the opening. The anti-floating well lid is simple in structure, convenient in operation, good in anti-floating effect, capable of effectively preventing a well lid floating phenomenon caused by upward impact force to the well lid when lower pressure is extremely great because of rainwater and the like, and capable of realizing opening of the well lid by rotating.

Owner:泗县宁宇市政设施科技有限公司

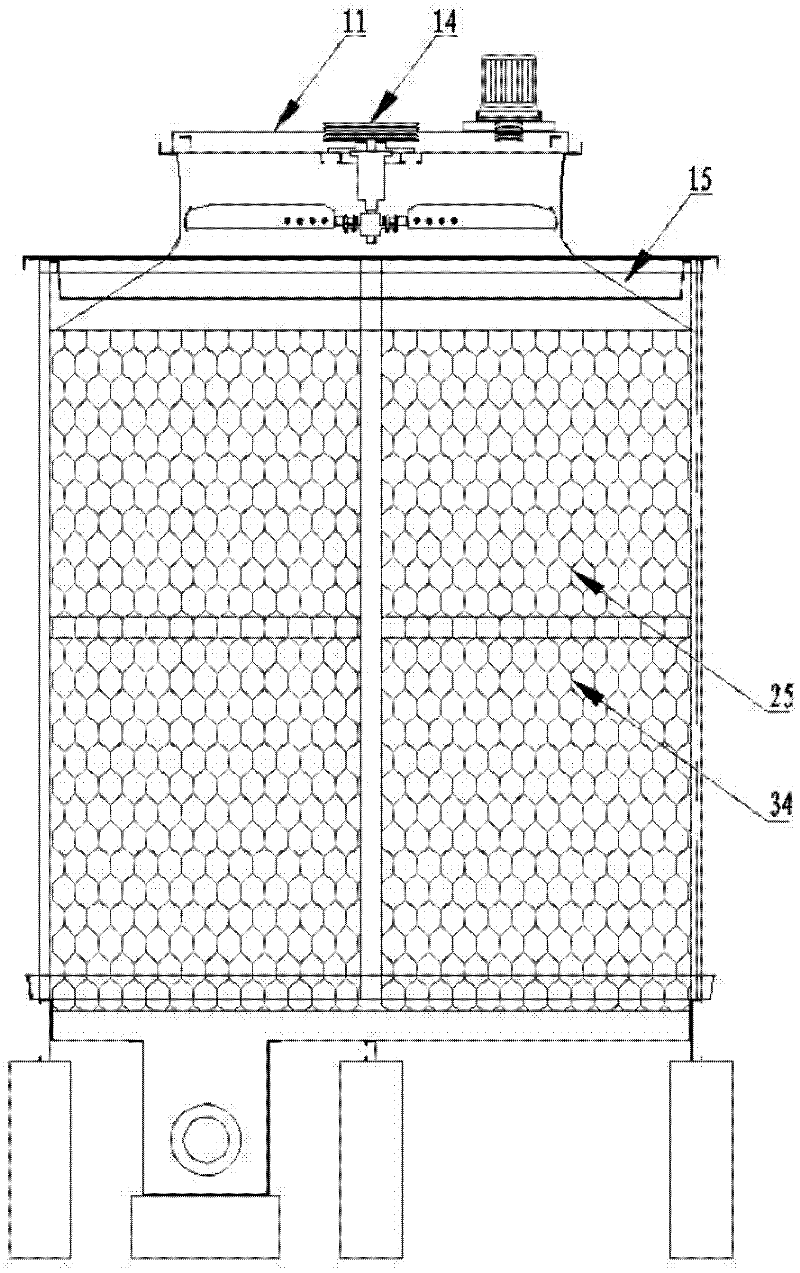

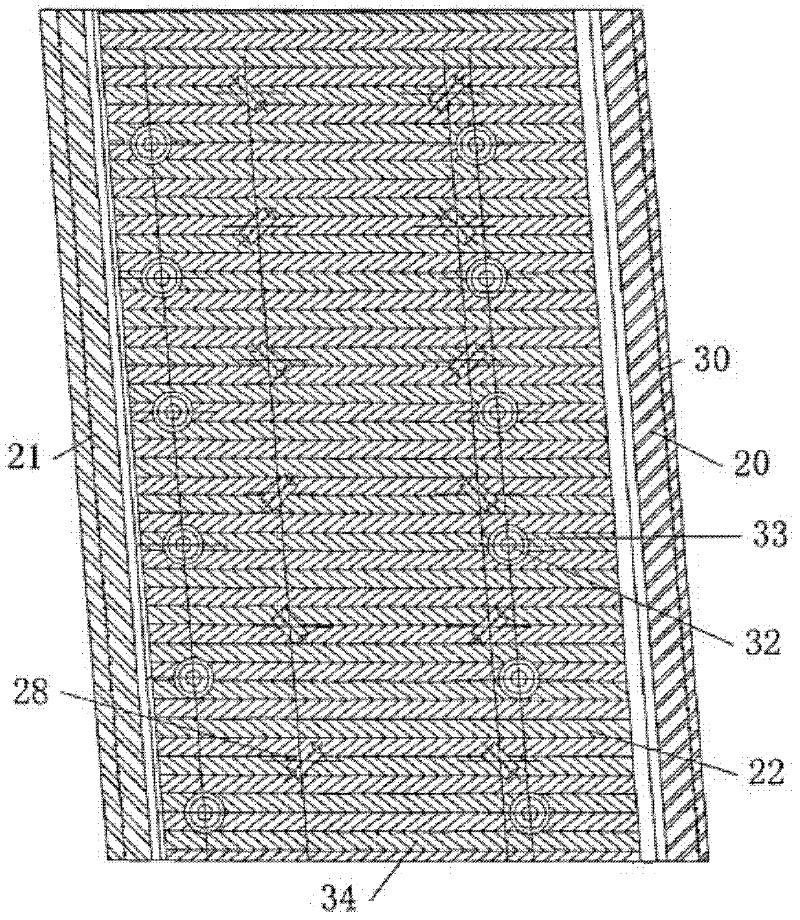

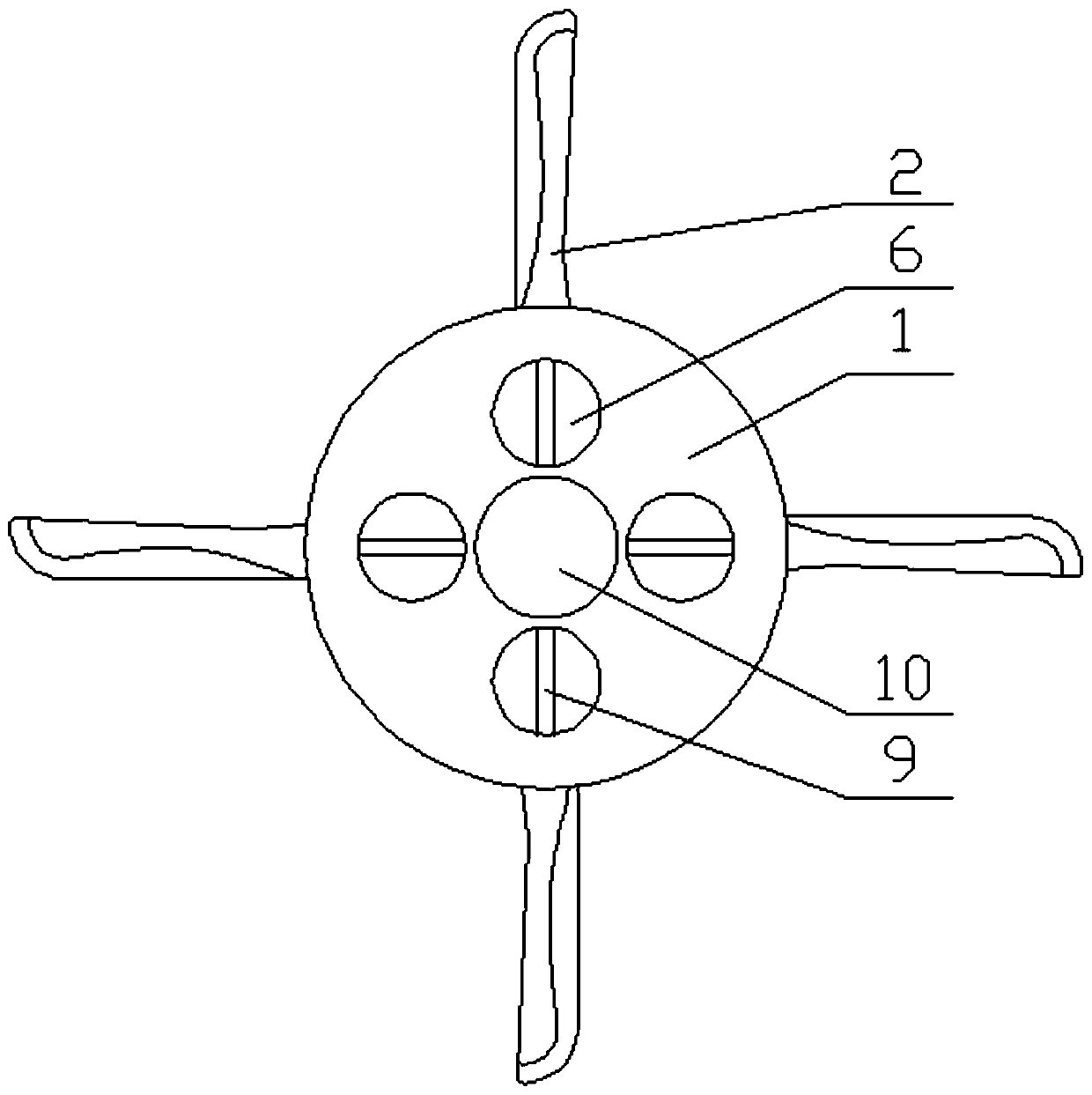

Square cross flow cooling tower with single-side air intake

InactiveCN102410746APrevent floating phenomenonAvoid enteringTrickle coolersRam-air intakeCooling tower

The invention discloses a square cross flow cooling tower with single-side air intake, which comprises a machine frame, a blow dryer on the top of the machine frame and a fan in the blow dryer; a water spraying device composed of a water spraying basin, a water distributing nozzle, water spraying filling and a water collecting basin is arranged in the internal part of the machine frame; the water spraying basin is located over the water spraying filling; the water distributing nozzle is installed in the water spraying basin; the water collecting basin is arranged below the water spraying filling; the water spraying filling is formed in a manner that a plurality of filling sheets are overlapped; each filling sheet is provided with an air inlet zone, a heat exchanging zone and an air outlet zone in sequence; a protruding ridge is arranged between the adjacent zones for preventing water from spraying; the air inlet zones and the air outlet zones of the adjacent filling sheets are contacted mutually to form honeycomb-shaped air inlets and air outlets respectively; and the water distributing nozzle comprises a main body pipe, a honeycomb duct and a petal-shaped disc which are arranged coaxially. When the square cross flow cooling tower with single-side air intake is applied, uniform water distribution can be realized and the cooling property of the cooling tower can be improved. Air comes into the air inlet of the water spraying filling and goes out of the air outlet and the air goes out of the top surface under the function of the fan. Consequently, the energy consumption of the fan and noise at the top of the tower can be reduced.

Owner:南京大洋冷却塔股份有限公司

Vacuum coating equipment for processing metallic films

InactiveCN106435513AHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses vacuum coating equipment for processing metallic films. The vacuum coating equipment comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism, wherein the feeding mechanism, the coating mechanism and the winding mechanism are arranged inside the vacuum chamber; the feeding mechanism comprises a first lifting mechanism and a feeding device; a preheating mechanism is arranged between the feeding mechanism and the coating mechanism; a first movable plate assembly adjusting an opening of a first evaporation boat is arranged in the opening area of the top of the first evaporation boat; a second movable plate assembly adjusting an opening of a second first evaporation boat is arranged in the opening area of the top of the second evaporation boat; film limiting devices are arranged between the feeding mechanism and the coating mechanism as well as between the coating mechanism and the winding mechanism; the winding mechanism comprises a fifth lifting mechanism and a winding device; and an extension end of the fifth lifting mechanism is matched with the winding device to drive the winding device to move up and down. The vacuum coating equipment has the advantages that the automation degree is high, supplementing and collecting are convenient and timely, preheating is uniform, the preheating degree can be adjusted, the processing requirements of the films of various models can be met and the coating thickness can be adjusted.

Owner:铜陵市铜创电子科技有限公司

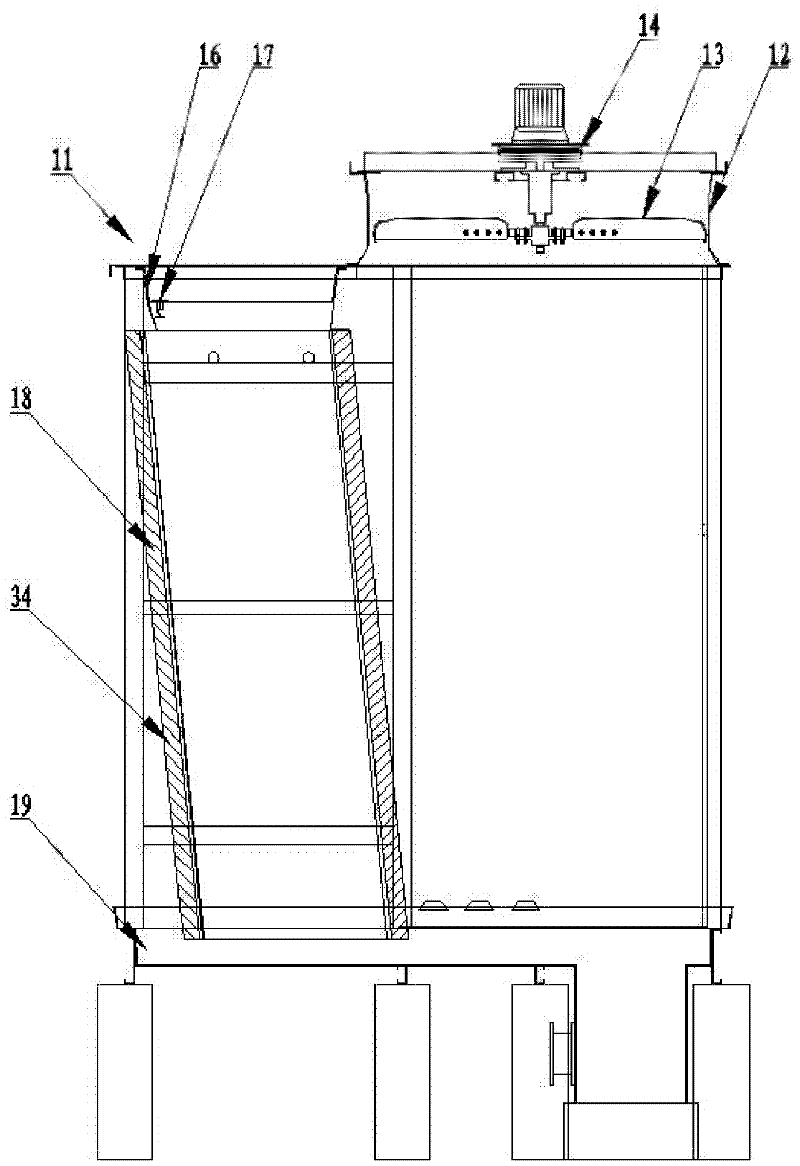

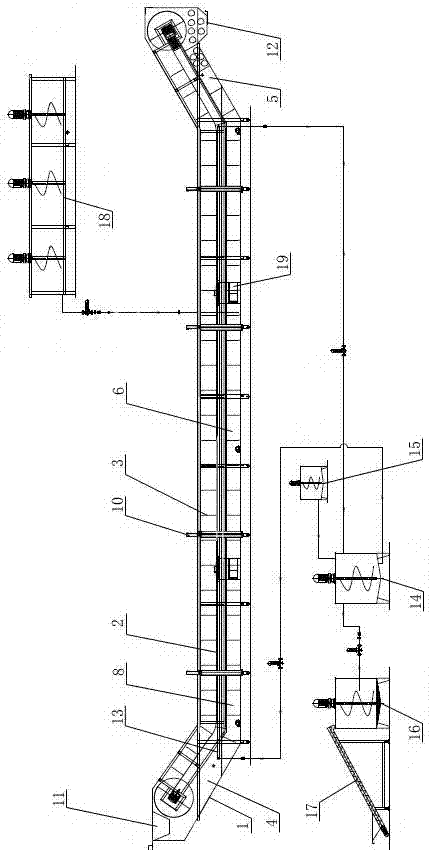

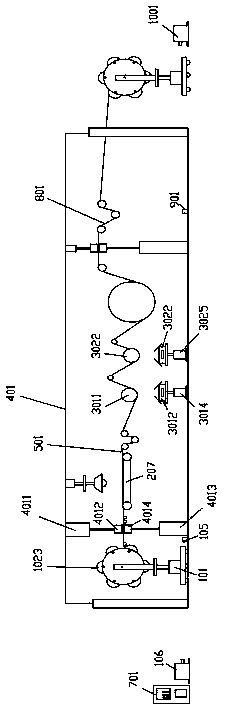

Continuous fermentation machine

ActiveCN102845819APrevent floating phenomenonMeet the process requirementsFruits/vegetable preservation using acidsFood shapingContinuous fermentationProcess requirements

The invention discloses a continuous fermentation machine which comprises a fermentation box and a conveying unit arranged in the fermentation box. The interior of the fermentation box forms a totally enclosed space through a seal cover arranged at the upper end face of the fermentation box; the conveying unit comprises a conveying belt in driving connection with a driving mechanism, the conveying belt is provided with a plurality of scraper plates, a feeding channel is formed between an input section of the conveying belt and a front section of the fermentation box, a discharging channel is formed between an output section of the conveying belt and a rear section of the fermentation box, a fermentation section is formed between of a middle section of the conveying belt and a middle section of the fermentation box, and in the discharging channel and the fermentation section, the peripheries of the scraper plates on the conveying belt closely abut with corresponding inner walls of the fermentation box. According to the invention, the sealed fermentation section is formed in the fermentation box, so materials are fermented in the fermentation section and are continuously conveyed under the action of the conveying belt; thus, the materials are effectively prevented from floating upward during fermentation, and process requirements for continuous production of a product are satisfied.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

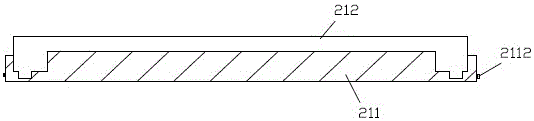

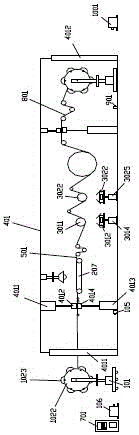

Secondary vacuum coating equipment for thickening metalized thin film

ActiveCN106399944ACoating thickness adjustableAdjust the amount of coatingVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses secondary vacuum coating equipment for a thickening metalized thin film. The equipment comprises a vacuum chamber, and a feeding mechanism, a coating mechanism and a winding mechanism which are arranged in the vacuum chamber. A first movable plate assembly which adjusts the size of an opening of a first evaporation boat is arranged in a top opening region of the first evaporation boat; a second movable plate assembly which adjusts the size of an opening of a second evaporation boat is arranged in a top opening region of the second evaporation boat; and thin film limiting devices are arranged between the feeding mechanism and the coating mechanism and between the coating mechanism and the winding mechanism. The secondary vacuum coating equipment disclosed by the invention has the advantages of being high in degree of automation, capable of supplementing and receiving materials conveniently, immediate, capable of uniformly preheating, adjustable in preheating quantity, suitable for machining films of various multiple models and capable of adjusting coating thickness.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

Feed cutter for feed puffing device

InactiveCN110432519ANo disintegrationGuaranteed limit effectFeeding-stuffScrew threadFeed processing

The invention discloses a feed cutter for a feed puffing device, and belongs to the technical field of feed processing. The feed cutter includes a cutter disc and a cutter head detachably mounted on the cutter disc, a mounting hole is formed in the cutter head, the cutter disc includes an upper top plate and a lower top plate, and an inserting opening for inserting the cutter head is formed in theouter surface of the cutter disc; the upper top plate is provided with a circular inserting groove for vertically placing a clamping block, evenly arranged strip-shaped plates corresponding to the circumference of the mounting hole are hinged in the clamping block, the clamping block is connected with a rotating ring body in a threaded mode, an abutting block with an inner diameter gradually increasing from top to bottom is fixed into the rotating ring body, the top ends of the strip-shaped plates abut against the inner side of the abutting block, and a circular sealing block which can seal the circular inserting groove is fixed to the top of the rotating ring body. According to the feed cutter, associated locking assemblies do not generate accidentally reverse effects, and the cutter head is not prone to loosing; a plastic sleeve does not need to be used, the floating phenomenon of the cutter can be effectively prevented during rotating, it is not necessary to replace the plastic sleeve frequently, the use cost is greatly lowered, and manpower is saved; and operation is convenient, and materials are not prone to entering the knife disc.

Owner:肥东县爱雯家庭农场

Vegetable washing device for selling and producing of vegetables

InactiveCN108157997AReasonable structural designReduce the process of groomingFood treatmentWater pipeLiquid level sensor

The invention discloses a vegetable washing device for selling and producing of vegetables. The vegetable washing device comprises a base, wherein drainage pipes are arranged at the top of the base; awashing tank is arranged at the top of the drainage pipe; a feeding opening is formed in the left side of the washing tank; a discharging opening is formed in the right side of the washing tank; partition boards are symmetrically arranged on the left side and the right side of the bottom of an inner cavity of the washing tank; a liquid level sensor is arranged on the right side of the left side partition board; a bubble generating device and an electronic oxygen activating device are arranged at the bottom of the inner cavity of the washing tank, and are located between the two sets of the partition boards; and a water inlet pipe is arranged on the right side of the right side partition board. The vegetable washing device disclosed by the invention is reasonable in structural design; under the effect of a sliding sleeve and a hanger frame, three steps of spraying washing, immersion washing and draining are sequentially performed on vegetables, so that the process of performing manualdredging is reduced, and the labor intensity of operators is reduced; and the immersion washing is performed after the spraying washing, so that the washing effect can be improved.

Owner:和县聂兴圩蔬菜种植有限责任公司

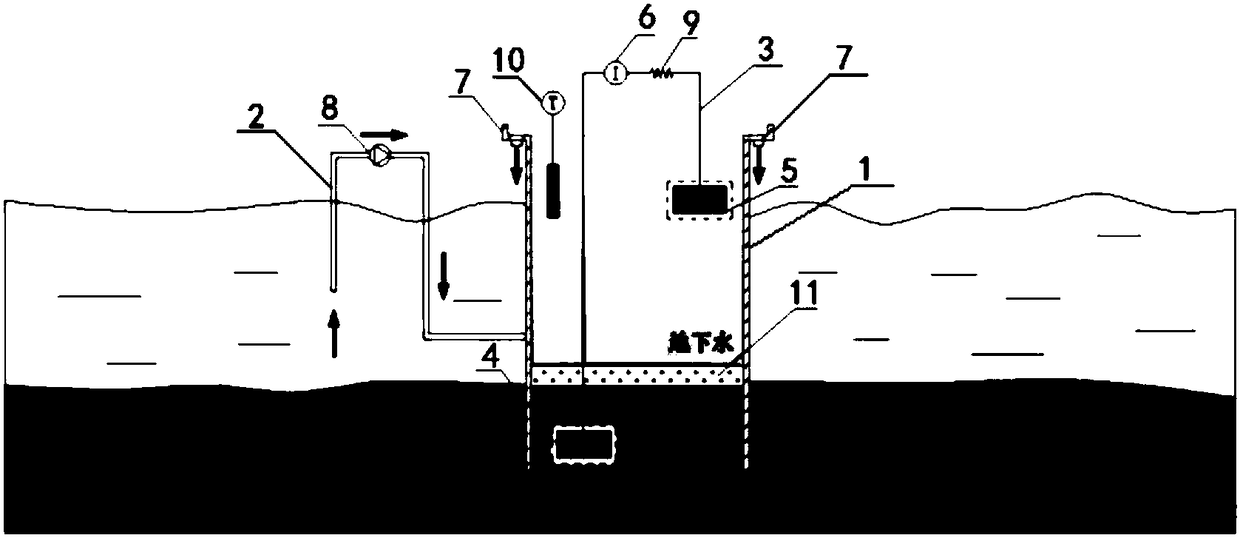

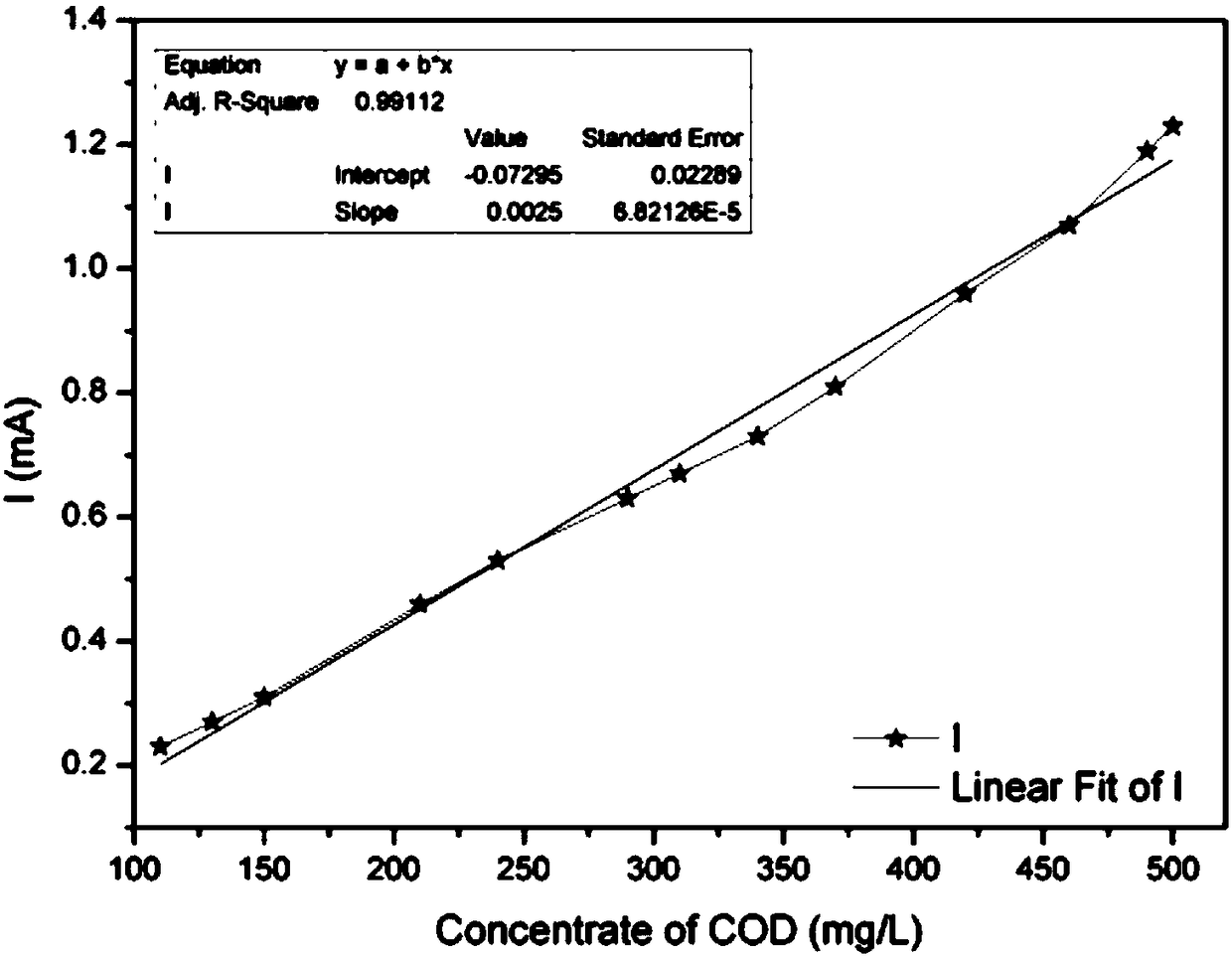

Microbial fuel cell-based underground water organic pollution monitoring device and method

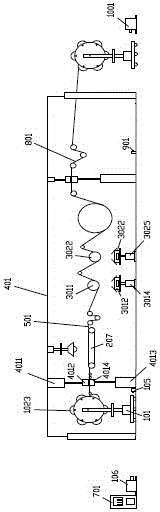

PendingCN108152352AEnhanced Response to PollutionImprove stabilityMaterial analysis by electric/magnetic meansWater environmentPower flow

The invention discloses a microbial fuel cell-based underground water organic pollution monitoring device and method and belongs to the technical field of water environment monitoring. The microbial fuel cell-based underground water organic pollution monitoring device comprises a device body, a water inlet pipe communicated with the device body and a battery device arranged inside the device body,wherein the battery device is composed of an anode chamber and a cathode chamber which are connected via wires, and a current monitoring device is arranged between the anode chamber and the cathode chamber; the top and the bottom of the device body are provided with openings, and the bottom of the device body is inserted into bottom mud of underground water; one end of the water inlet pipe is arranged inside the underground water, and the other end of the water inlet pipe is communicated with the device body; the anode chamber is arranged inside the bottom mud inside the device body, and thecathode device is arranged in the underground water inside the device body. The microbial fuel cell-based underground water organic pollution monitoring device can achieves real-time in-situ underground water monitoring and is applicable to in-situ field work and high in monitoring precision.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

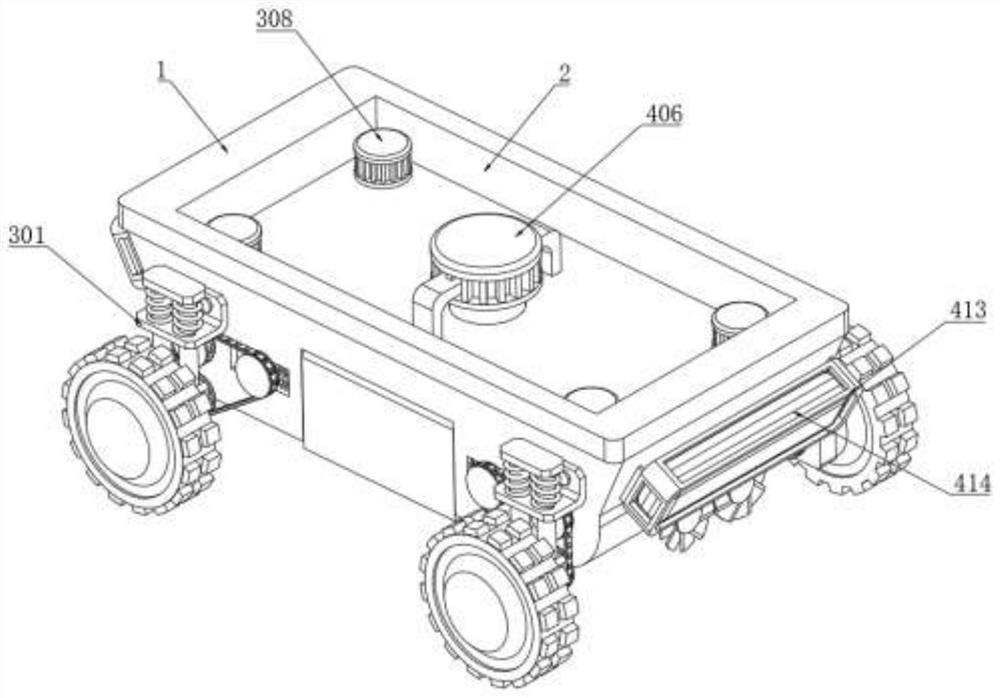

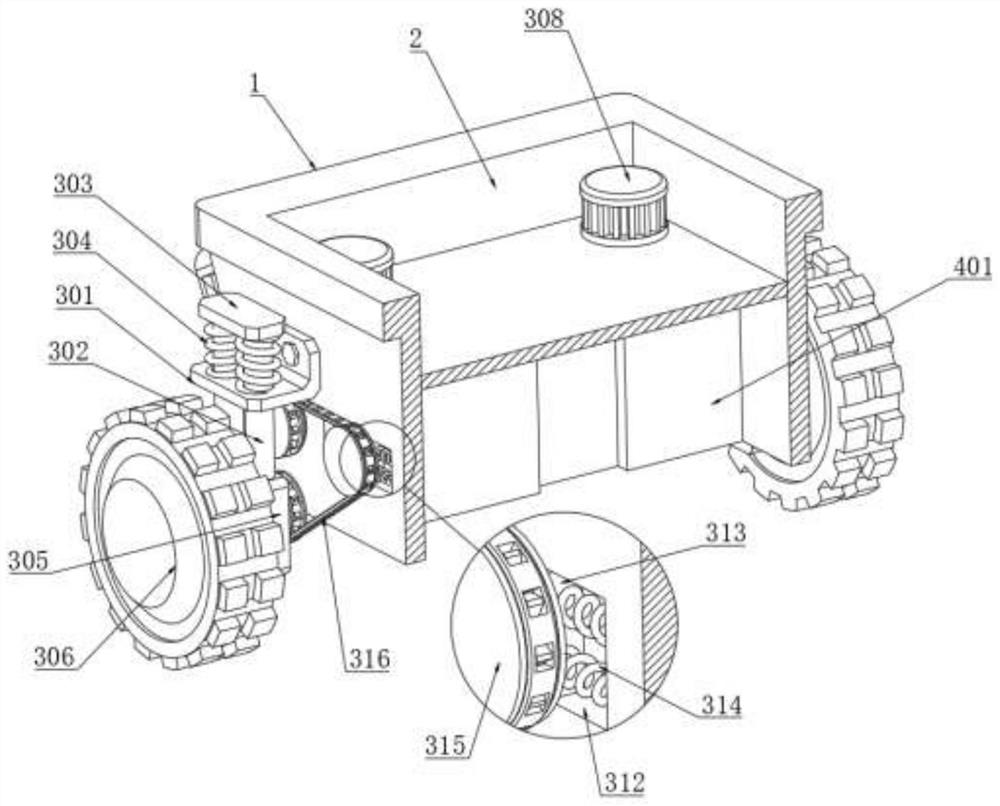

Robot capable of walking in all terrains

PendingCN114475112AEasy to passAvoid offsetAmphibious vehiclesPropulsion power plantsElectric machineryDrive motor

The robot capable of adapting to all-terrain walking comprises a walking robot base, a containing groove is formed in the walking robot base, overall stable supporting mechanisms are arranged at the two ends of the containing groove and the two ends of the walking robot base correspondingly, and a driving motor drives a rotating rod to rotate; according to the walking robot, the structure is scientific and reasonable, using is safe and convenient, an overall stable supporting mechanism is arranged, the driving motor drives the rotating rod to rotate, the driving gear and the driven gear are matched, the rotating rod is driven to rotate through the driving motor, and the walking robot is driven to move through the driving gear and the driven gear. The power is transmitted, the chain wheel and the chain are driven to rotate, then the power is transmitted again, the air cushion wheel is driven to rotate, the walking robot base is pushed to move, the top plate and the supporting vertical rod are pulled to slide through the telescopic characteristic of the reset spring, and the positions of the fixing plate and the air cushion wheel are changed.

Owner:SHENYANG JIANZHU UNIVERSITY

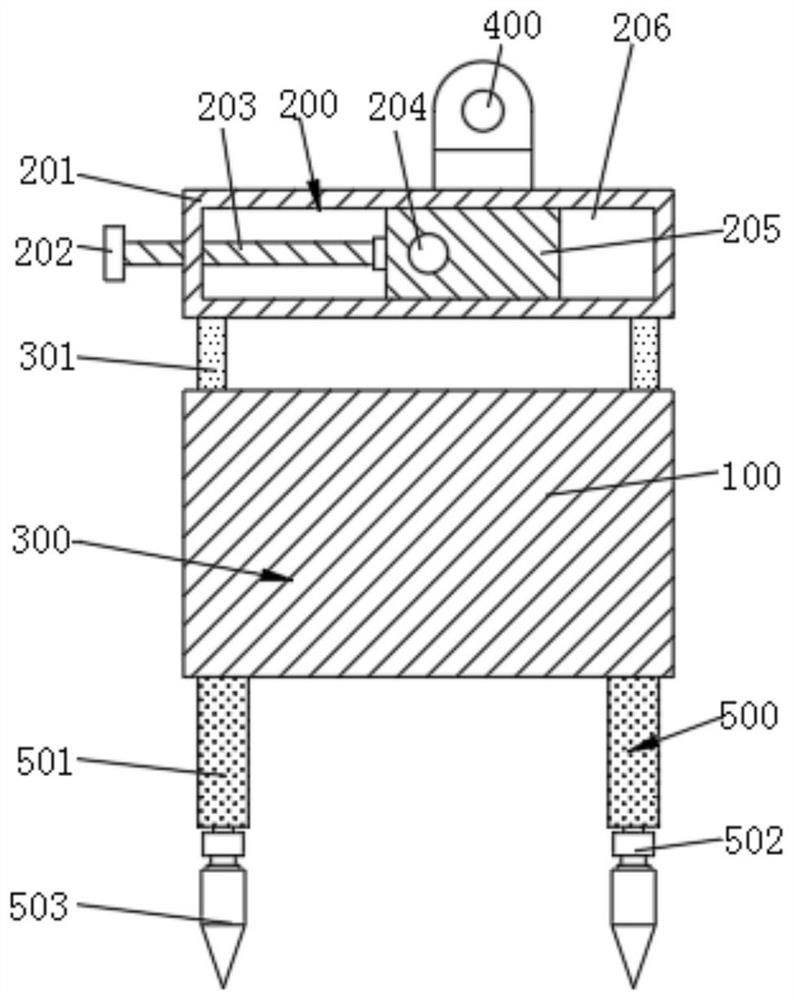

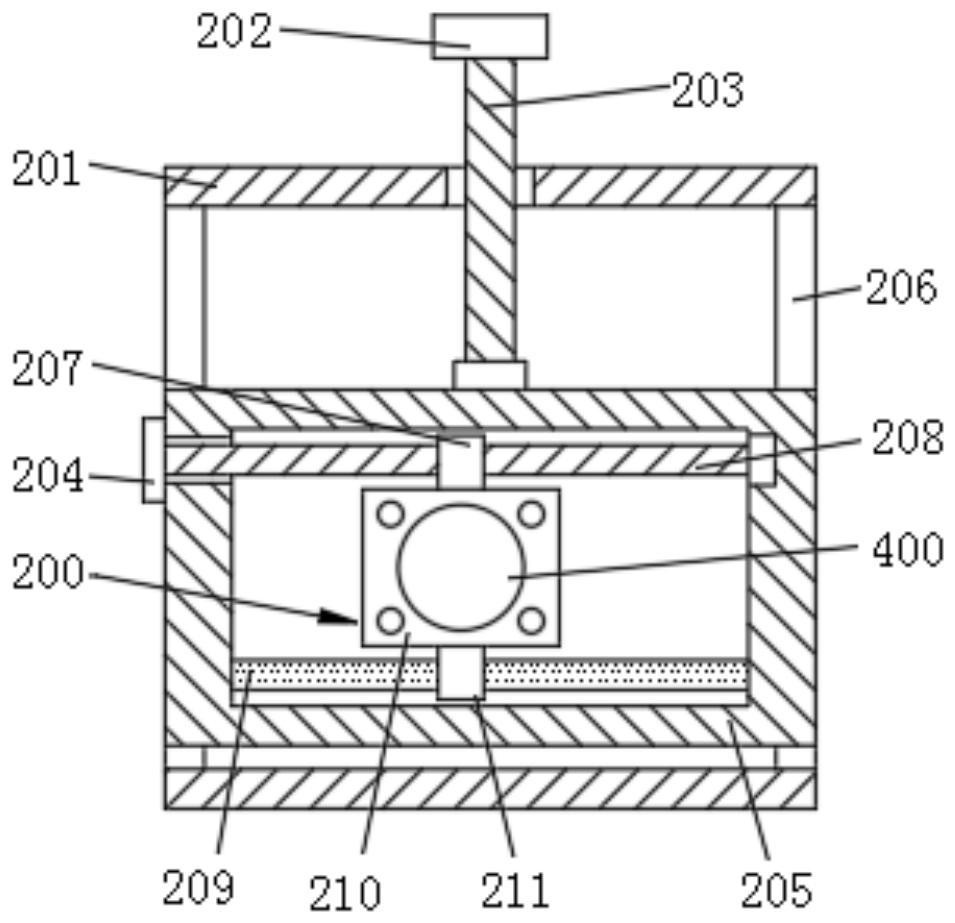

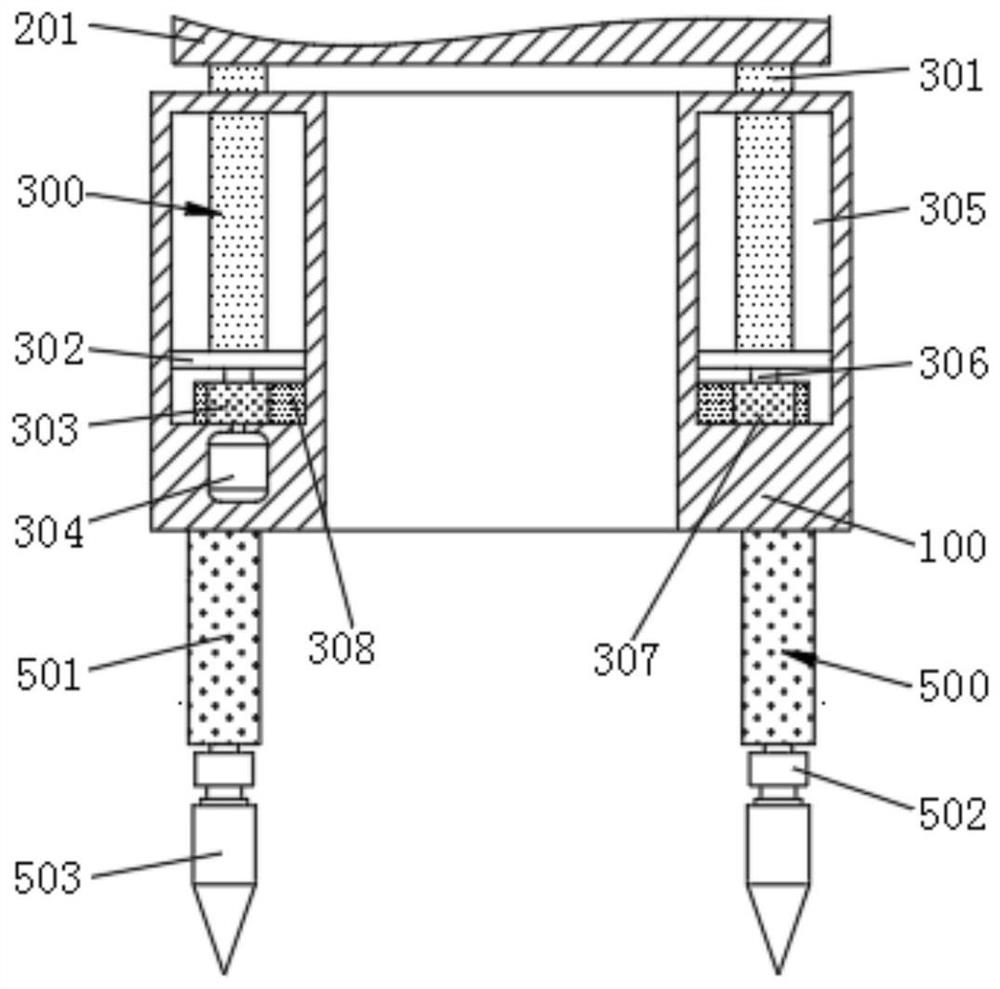

Positioning device for highway engineering surveying and mapping

InactiveCN112696573AEasy to fixFixed-point preventionSurveying instrumentsStands/trestlesStructural engineeringControl theory

The invention discloses a positioning device for highway engineering surveying and mapping. The positioning device comprises a first square frame, a lifting mechanism is arranged in the first square frame, stabilizing mechanisms are arranged at the lower end of the first square frame, a position adjusting mechanism is arranged on the first square frame and comprises a second square frame, the second square frame is located above the first square frame, a third square frame is arranged in the second square frame and is slidably connected with sliding grooves formed in the two sides of the inner wall of the second square frame, a first lead screw is arranged in the third square frame, a connecting rod is in threaded connection with the first lead screw, a support seat is arranged at one end of the connecting rod, a sliding rod is arranged in the third square frame, a sliding block is arranged on the sliding rod and is connected with the support seat, and a surveying and mapping instrument is arranged on the support seat. According to the positioning device for the highway engineering surveying and mapping, the surveying and mapping instrument can be driven by the first lead screw to move forwards and backwards and can be driven by a second lead screw to move leftwards and rightwards, position adjusting is performed on the surveying and mapping instrument, point fixing of the surveying and mapping instrument is facilitated, and the situation that the surveying and mapping instrument is difficult to fix by moving a triangular support and the falling risk of the instrument is easily increased is prevented.

Owner:裴超

Method for enhancing precipitation effect of acid precipitated proteins

InactiveCN102757475APrevent floating phenomenonImprove the separation effectPeptide preparation methodsDefoaming AgentsChemistry

The invention discloses a method for enhancing precipitation effect of acid precipitated proteins, which is implemented in a way that: in the protein extraction process by alkali extraction and acid precipitation, a defoaming agent is added to the extraction and acid precipitation sections to ensure that no protein or air emulsion system is formed in the extraction process; and a pipe bundle or ageing can is added to the rear part of the acid precipitation tank in the acid precipitation process, so that the protein liquid in the acid precipitation tank enters the pipe bundle or ageing can before separation and stays for 10-30 minutes, thereby prolonging the retention time of the protein liquid at the acid precipitation section. The invention effectively prevents proteins from floating in the acid precipitation process, enhances the separating effect, prolongs the retention time of the protein liquid at the acid precipitation section, and directly enhances the protein yield.

Owner:谷神生物科技集团有限公司

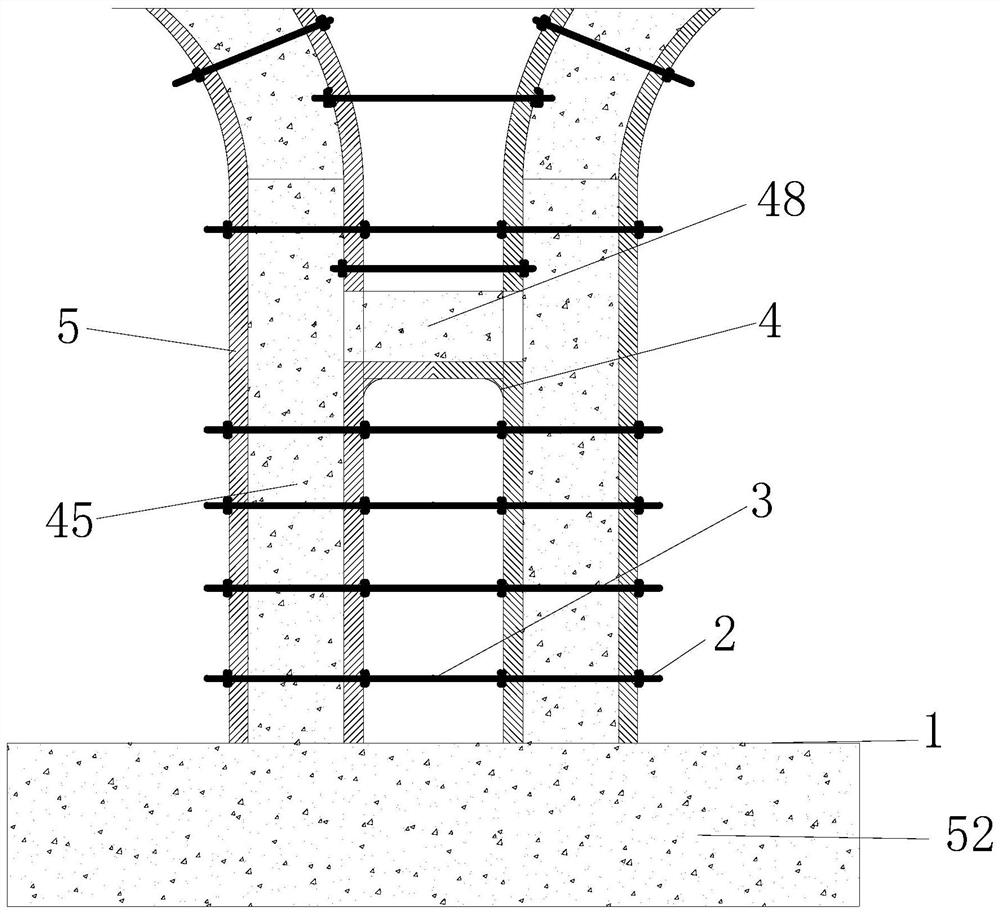

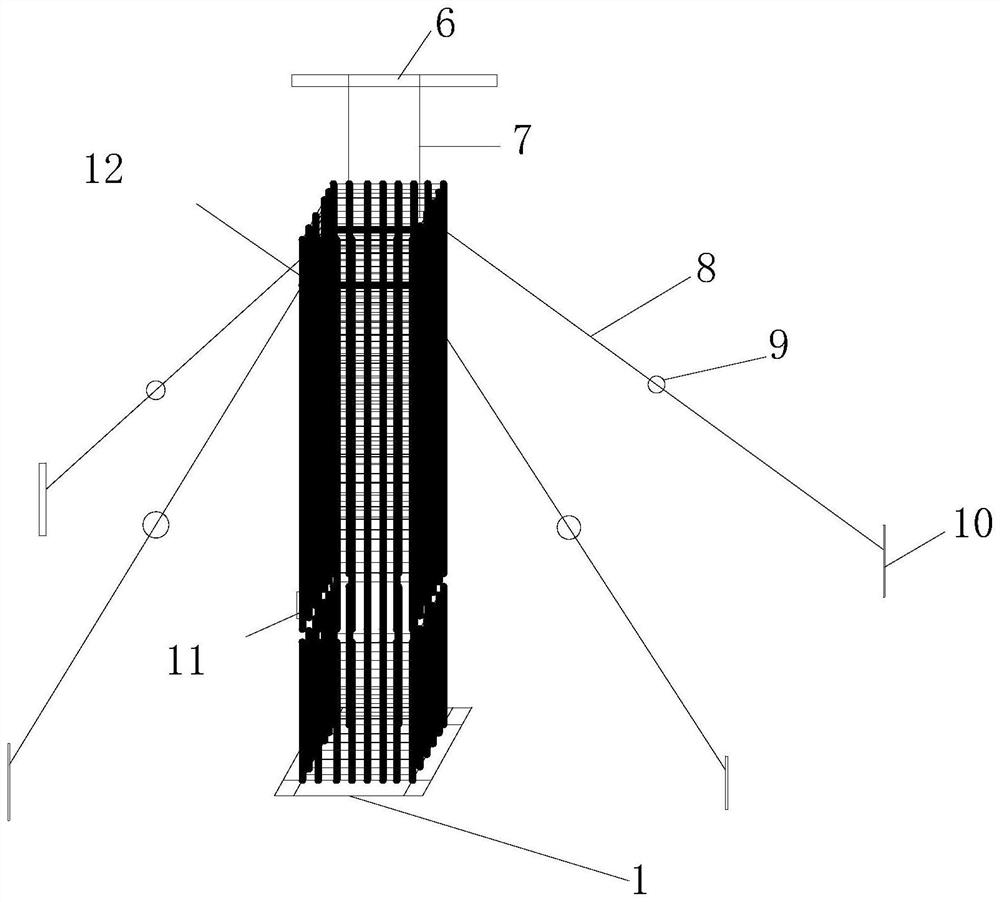

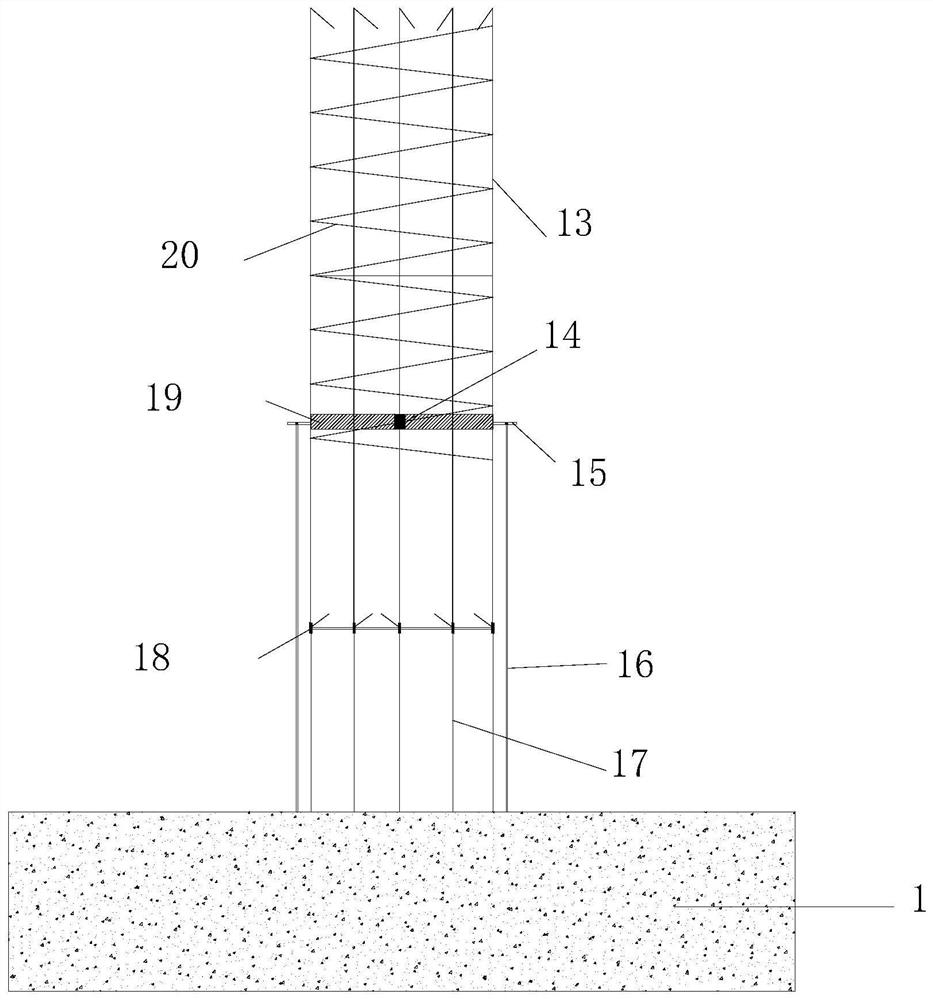

Bridge high pier construction method

ActiveCN114561873APrevent floating phenomenonImprove construction accuracyClimate change adaptationBridge structural detailsSupporting systemArchitectural engineering

The invention discloses a construction method for a high pier of a bridge. The construction method comprises the following specific steps: 1) constructing a bearing platform; (2) pier column steel bar construction; (3) constructing a pier column template; (4) pouring construction; and (5) pier column maintenance. According to the invention, the pier column main reinforcements are connected with the steel pipe frame through the telescopic rods, so that the phenomenon that the reinforcements float upwards when the bearing platform is poured is prevented, and the construction precision of the pier column pre-embedded main reinforcements is improved; an upper-layer reinforcement cage is temporarily welded and fixed through a fixing frame, bracket ribs are arranged on the fixing frame and arranged on the upper portion of a welding seam, one end of a telescopic rod is connected with a hoop lug plate, the hoop lug plate and a hoop body provide a temporary working platform for reinforcement cage welding construction, and the welding construction difficulty of the upper-layer reinforcement cage is lowered; a straining beam hoop formwork supporting system and a steel formwork opposite-pulling self-stabilizing system are arranged on the pier column, and formwork construction is convenient and fast; and a cold joint template is adopted when the concrete is poured for several times, and the over-poured concrete is recycled from the slurry leakage hole, so that the cold joint chiseling construction is reduced.

Owner:杭州萧山交通建设管理有限公司

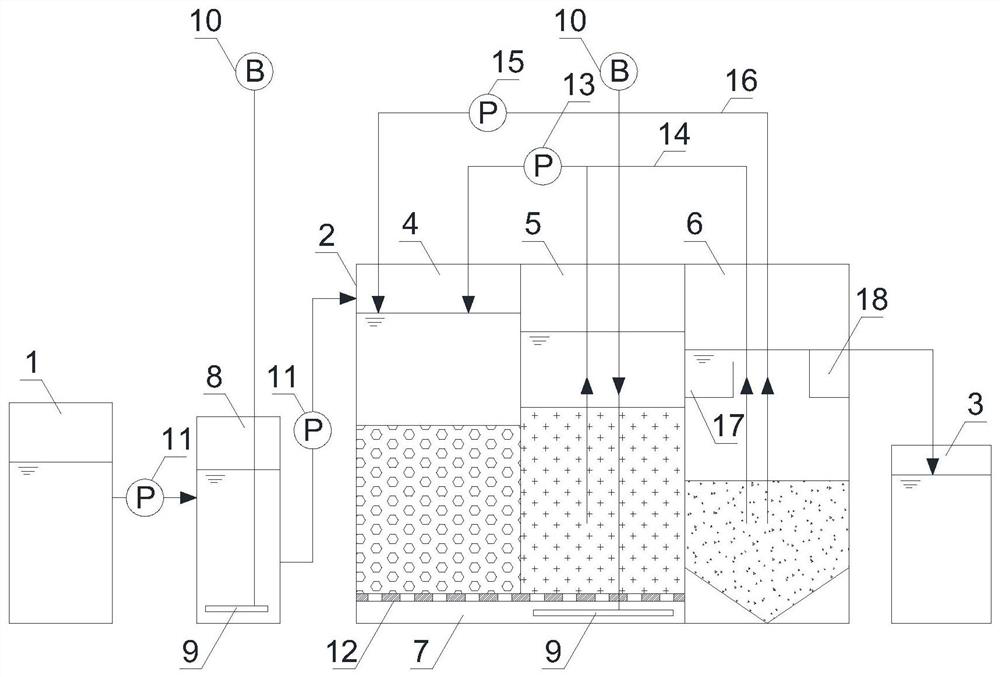

Integrated sewage treatment equipment with front-end pretreatment function

PendingCN111718060AImprove the environmentPrevent long-term accumulation and deterioration of odorSpecific water treatment objectivesWater aerationWater dischargeWater production

The invention discloses the field of integrated sewage treatment equipment with a front-end pretreatment function. The equipment comprises an adjusting tank, an integrated sewage treater, a water production tank and a water distribution well, wherein algae and photosynthetic bacteria are arranged in the water distribution well; an aerator is arranged at the bottom of the water distribution well, and the aerator is connected with an air blower; the adjusting tank is connected to the water distribution well through a water pump; the lower part of the water distribution well is connected into ananoxic tank through a water pump. Under the stirring action of the aerator in the water distribution well, on the premise that dissolved oxygen in the tank is not increased, the phenomena that sludgeis accumulated for a long time, deteriorates and smells and floats upwards due to anaerobic reaction are prevented, and the effect of improving the environment in the tank is achieved; an algal-bacterial symbiotic mode is formed in the water distribution well, so that the sewage pretreatment effect is greatly improved, the water feeding load of integrated sewage treatment equipment is obviously reduced, and the water discharge stability of the system is enhanced. The operation is simple, the energy consumption is reduced, and the investment cost is saved.

Owner:CAPITAL GREINWORTH ENVIRONMENTAL CORP

A metallized film vacuum coating machine

InactiveCN106222627BHigh degree of automationConvenience for feeding/receivingVacuum evaporation coatingSputtering coatingVacuum chamberVacuum coating

The invention discloses a metallized film vacuum coating machine. The metallized film vacuum coating machine comprises a vacuum chamber, a feeding mechanism, a coating mechanism and a winding mechanism. The feeding mechanism, the coating mechanism and the winding mechanism are arranged in the vacuum chamber. The feeding mechanism comprises a first lifting mechanism and a feeding device. A preheating mechanism is arranged between the feeding mechanism and the coating mechanism. A first movable plate assembly adjusting the size of an opening of a first evaporator boat is arranged in the top opening area of the first evaporator boat. A second movable plate assembly adjusting the size of an opening of a second evaporator boat is arranged in the top opening area of the second evaporator boat. A film clamping device is arranged between the feeding mechanism and the coating mechanism. A film clamping device is arranged between the coating mechanism and the winding mechanism. The winding mechanism comprises a fifth lifting mechanism and a winding device. The telescopic end of the fifth lifting mechanism is matched with the winding device and used for driving the winding device to move up and down. The metallized film vacuum coating machine has the advantages that the automation degree is high, material supplementary / material receiving is convenient and in time, preheating is uniform, preheating quantity is adjustable, the metallized film vacuum coating machine is suitable for machining of various models of films, and the coating thickness is adjustable.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

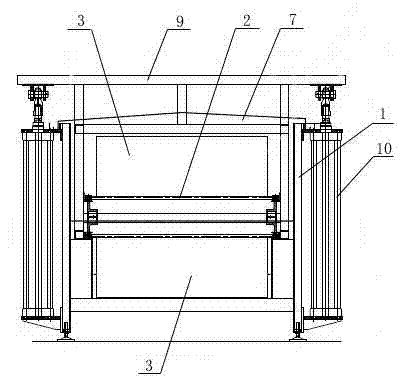

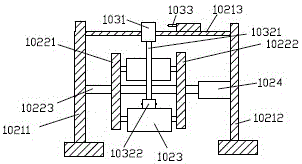

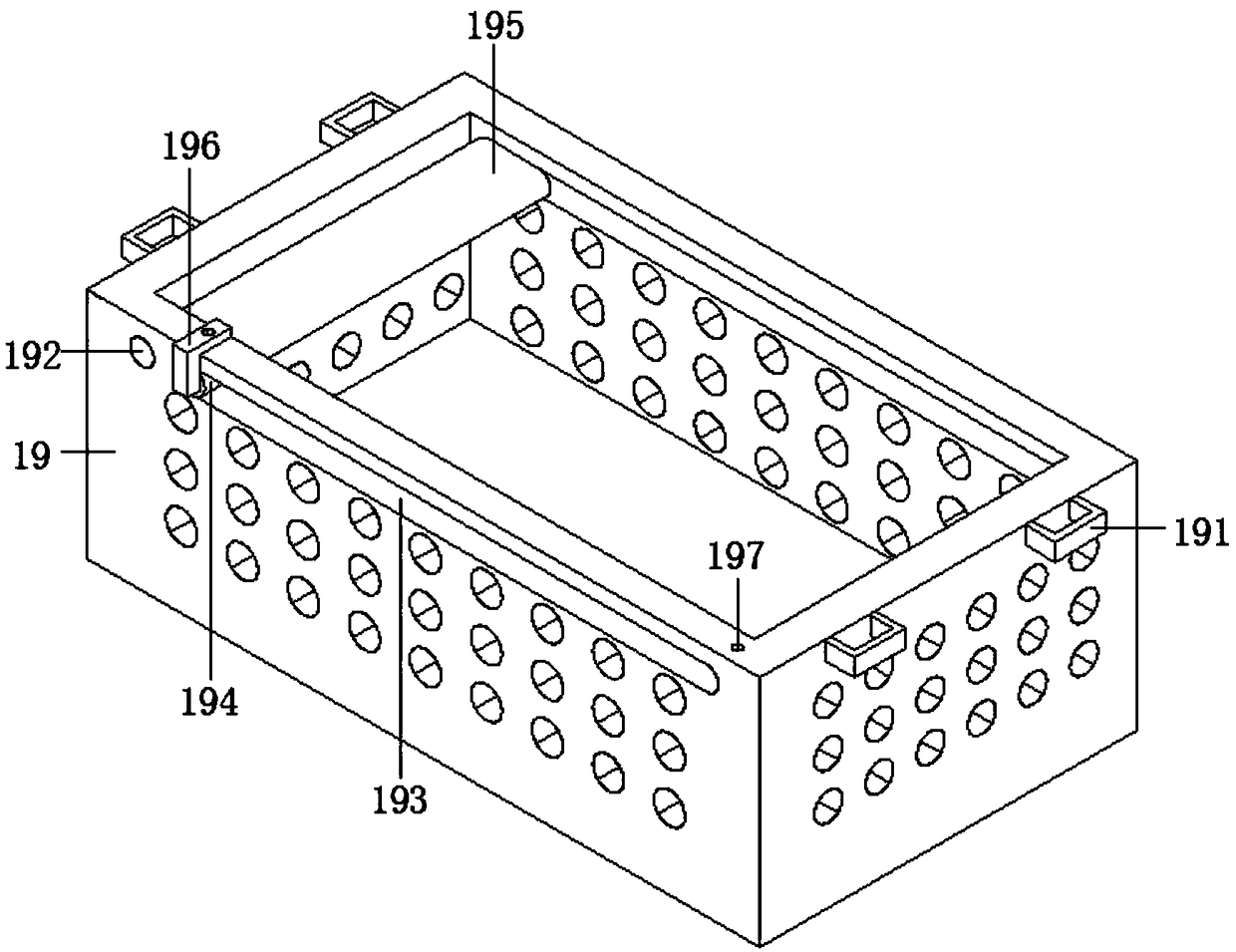

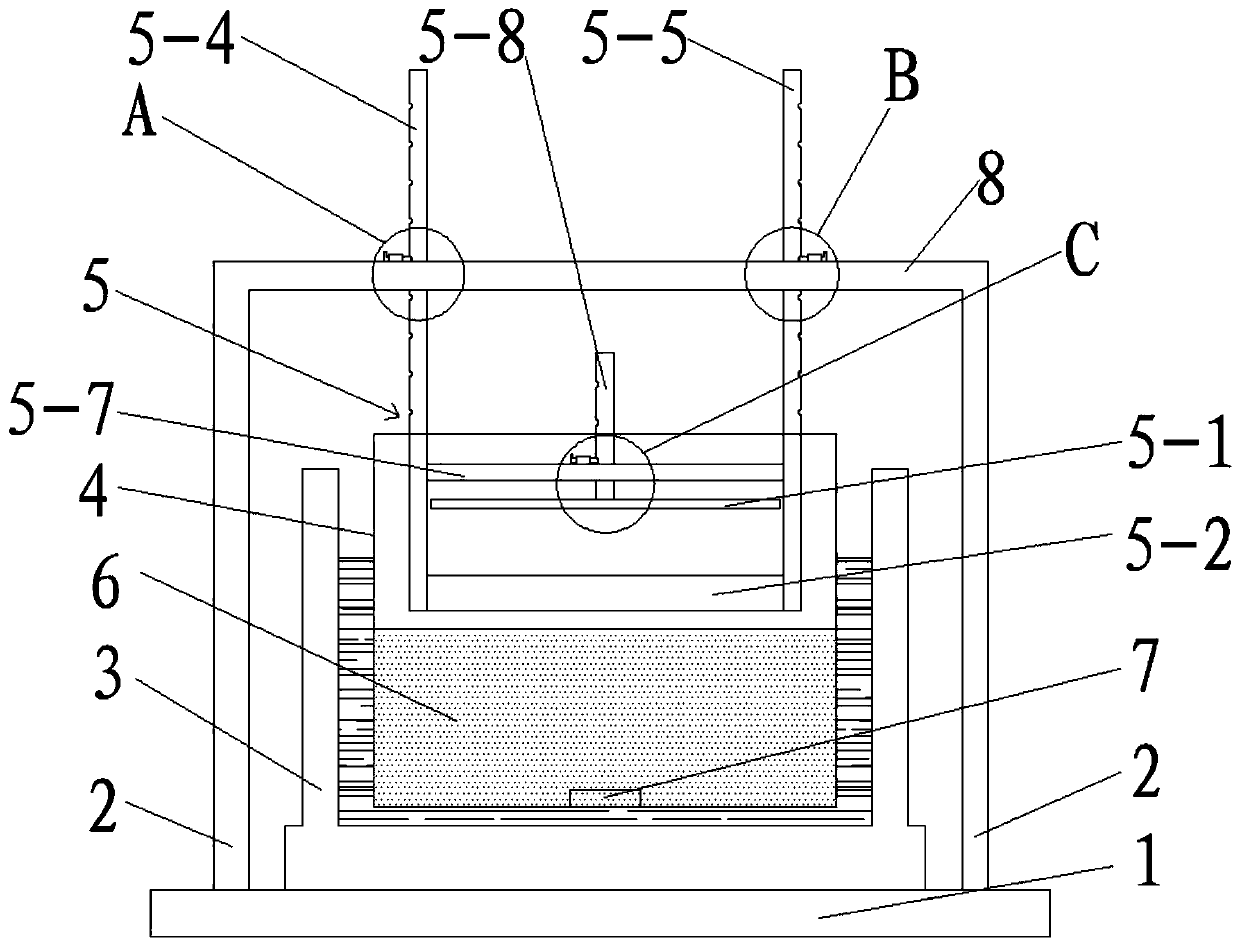

Hollow metal material preparing device and method

ActiveCN111558712AEasy to buyPrevent floating phenomenonTransportation and packagingMetal-working apparatusBatch productionEngineering

The invention discloses a hollow metal material preparing device which comprises a workbench and a fixing frame. The fixing frame is composed of stand columns and a first beam provided with a throughhole and a plug pin. A magnetic stirring water bath pot and a slurry container are arranged in an inner cavity of the fixing frame. A dipping basket is arranged in the slurry container. The dipping basket comprises a basket frame, a porous base plate and a porous cover plate. The two sides of the basket frame are connected with a first lifting rod and a second lifting rod connected with a second beam separately. A third lifting rod is connected to the porous cover plate. The invention further discloses a hollow metal material preparing method. According to the method, after an inner supportingbody is pretreated and then dipped in metal powder slurry, then, sintering is performed, and a hollow metal material is obtained. The phenomenon that the inner supporting body floats in the slurry isavoided through the dipping basket, the defect that residual falling, rolling and secondary contamination of the inner supporting body appear is avoided, batched production is achieved, and the prepared hollow metal material has the advantages of being high in void ratio, high in strength and low in mass.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Slitting device used for thin film slitting machine

The invention provides a slitting device used for a thin film slitting machine. The slitting device comprises two opposite fixed plates, a first transmission guide wheel, a cutter groove wheel transmission shaft and a slitting shaft which are parallel are arranged between the two fixed plates, the first transmission guide wheel and the cutter groove wheel transmission shaft are the same in height,the slitting shaft is arranged above the cutter groove wheel transmission shaft, cutter groove wheels are arranged at the two ends of the cutter groove wheel transmission shaft, and are arranged on the cutter groove wheel transmission shaft in a sleeving manner, multiple grooves are formed in the cutter groove wheel transmission shaft, and the cutter groove wheels are clamped in the grooves; twocutter rests are arranged on the slitting shaft in a sleeving manner, and a slitting cutter is arranged on each cutter rest in an erected manner. The cutter groove wheels arranged on the cutter groovewheel transmission shaft in a sleeving manner are used, the cutter groove wheels can support the edge of the thin film, the phenomenon that the edge of the thin film is suspended is avoided, it is ensured that a cutter can cut into the edge portion of the film, the cutter sliding phenomenon can be avoided, narrow edge can be cut, and thin film waste is reduced.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Forming mold for aircraft skin part

ActiveCN103464561BRaise the forming limitReduce the number of deep drawingShaping toolsMaterials scienceAirplane

The invention relates to a forming die of a skin part for an airplane. The forming die comprises a compression block, a male die, a female die, a binder ring and a pressing plate, wherein the male die comprises a straight wall part and a forming part; the female die is provided with a cavity for holding billets and liquid; the binder ring comprises an upper binder ring and a lower binder ring; the lower binder ring can be slidably located on the female die in the longitudinal direction, and is provided with a second penetrating hollow part adapt to a lower straight wall part; the upper binder ring can be detachably fixed on the lower binder ring, and is provided with a first up-and-down penetrating hollow part; the upper binder ring is detachably connected with a second pressurizing source, so that the compression block and the male die sequentially penetrate through the first hollow part and the second hollow part under the action of a first pressurizing source, and when the forming part of the male die is used for forming the billets in the cavity of the female die, the second pressurizing source presses the upper binder ring and the lower binder ring on the female die. According to the forming die of the skin part for the airplane, the resilience after a part is formed is effectively reduced, and the forming accuracy and the surface quality are improved.

Owner:SHANGHAI AIRCRAFT MFG +1

Composite separator for secondary battery

PendingCN110676418AReduce voidsPrevent floating phenomenonLi-accumulatorsCell component detailsComposite materialElectrical battery

Owner:SK INNOVATION CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com