High-hardness impact-resisting heat-insulation foaling plastic

A foamed plastic and impact-resistant technology, applied in the field of plastics, can solve the problems of poor thermal insulation effect, weak impact resistance, insufficient hardness of foamed plastics, etc., to achieve stability, improve hardness and impact resistance. , the effect of uniform cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

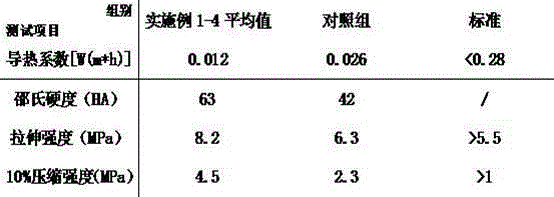

Examples

Embodiment 1

[0013] A high-hardness impact-resistant heat-insulating foamed plastic proposed by the present invention, its raw materials include: 20 parts of polystyrene resin, 40 parts of polyurethane resin, 20 parts of phenolic resin, 10 parts of urea-formaldehyde resin, diethylamine-based 4 parts of propylamine DEAPA, 2 parts of azodicarbonamide AC, 0.9 parts of polydimethylsiloxane-polyoxyalkylene copolymer, 1 part of talc powder, 0.3 parts of quartz powder, 1.4 parts of hollow microspheres, 1 part of bentonite, diatom 20 parts of soil, 10 parts of calcium carbonate, 5 parts of polyethylene-octene copolymer elastomer, 12 parts of glass fiber, polydimethylsiloxane-polyoxyalkylene copolymer is polydimethylsiloxane and polyoxyalkylene It is obtained by blending and modifying, and the polyethylene-octene copolymerized elastomer is obtained by blending and modifying polyethylene and octene;

[0014] During the preparation process, polystyrene resin, polyurethane resin, phenolic resin and ur...

Embodiment 2

[0016] A high-hardness impact-resistant heat-insulating foamed plastic proposed by the present invention, its raw materials include: 21 parts of polystyrene resin, 41 parts of polyurethane resin, 21 parts of phenolic resin, 11 parts of urea-formaldehyde resin, diethylamine base 5 parts of propylamine DEAPA, 3 parts of azodicarbonamide AC, 1 part of polydimethylsiloxane-polyoxyalkylene copolymer, 2 parts of talc powder, 0.4 part of quartz powder, 1.5 parts of hollow microspheres, 2 parts of bentonite, diatom 21 parts of soil, 11 parts of calcium carbonate, 6 parts of polyethylene-octene copolymer elastomer, 13 parts of glass fiber, polydimethylsiloxane-polyoxyalkylene copolymer is polydimethylsiloxane and polyoxyalkylene It is obtained by blending and modifying, and the polyethylene-octene copolymerized elastomer is obtained by blending and modifying polyethylene and octene;

[0017] During the preparation process, polystyrene resin, polyurethane resin, phenolic resin and urea-...

Embodiment 3

[0019] A high-hardness impact-resistant heat-insulating foamed plastic proposed by the present invention, its raw materials include by weight: 22 parts of polystyrene resin, 42 parts of polyurethane resin, 22 parts of phenolic resin, 12 parts of urea-formaldehyde resin, diethylamine base 6 parts of propylamine DEAPA, 4 parts of azodicarbonamide AC, 1.1 parts of polydimethylsiloxane-polyoxyalkylene copolymer, 3 parts of talc powder, 0.5 parts of quartz powder, 1.6 parts of hollow microspheres, 3 parts of bentonite, diatom 22 parts of soil, 12 parts of calcium carbonate, 7 parts of polyethylene-octene copolymer elastomer, 14 parts of glass fiber, polydimethylsiloxane-polyoxyalkylene copolymer is polydimethylsiloxane and polyoxyalkylene It is obtained by blending and modifying, and the polyethylene-octene copolymerized elastomer is obtained by blending and modifying polyethylene and octene;

[0020] During the preparation process, polystyrene resin, polyurethane resin, phenolic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com