Metallized film breadth linearly adjustable type splitting machine and unit thereof

A metallized film and slitting machine technology, applied in metal processing, thin material processing, sending objects, etc., can solve the problems of reduced cutting accuracy, film slippage, looseness, etc., to shorten film rolling time, achieve work efficiency, Improve the effect of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further describe the present invention, it is further described below in conjunction with embodiment.

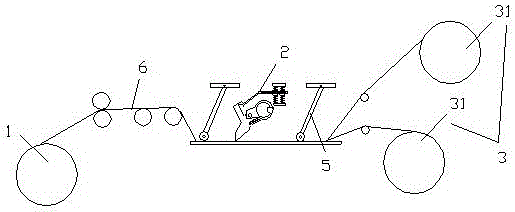

[0045] Such asfigure 1 As shown, the present invention discloses a metallized film width-adjustable linear slitting machine, which includes a feeding mechanism 1 , a slitting mechanism 2 , and a film rolling mechanism 3 . The feeding mechanism 1, the cutting mechanism 2, and the film rolling mechanism 3 are sequentially arranged on the frame according to the technological process from front to back. In the present invention, guide rollers and tension rollers are also arranged on the frame, and in some embodiments, traction pair rollers are also arranged. The transmission power of the film 6 of the present invention is preferably driven by the film rolling mechanism 3 . The feeding mechanism 1 of the present invention is a film feeding mechanism of the prior art.

[0046] The present invention rotates through the film rolling mechanism 3, pulls the film 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com