Bath smelting side-blowing jet flow gush type enhanced stirring method

A molten pool smelting and stirring method technology, applied in the field of metallurgy, can solve the problems affecting the rate of slagging reaction in the molten pool, the difficulty of blowing through the slag layer with oxygen-enriched air, and the short residence time of oxygen-enriched air, so as to increase the effective smelting area, prevent air bubbles from adhering to the wall and floating up, and the effect of good dynamic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

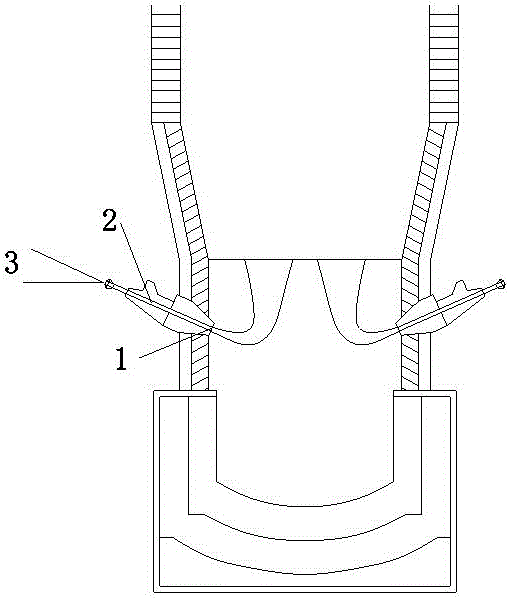

[0017] like figure 1 As shown, the side-blowing furnace in the copper smelting workshop of a certain smelting plant adopts the side-blowing jet flow intensified mixing method for melting pool smelting, the diameter of the nozzle is reduced from 5cm to 3cm, the wind pressure is increased from 0.1MPa to 0.25MPa, and the outlet flow rate It can reach 200m / s to ensure that the oxygen-enriched air (the oxygen content in the oxygen-enriched air is 23wt%) is blown into the molten pool in the form of a jet. The downward inclination angle of the nozzle is set to 25°, which further enhances the lateral penetration depth of the gas jet, reduces the erosion and corrosion effect of the bubbles on the furnace wall, and increases the service life of the furnace wall from 1 year to 2 years. The gas rate and turbulent kinetic energy are increased by more than 20%, which promotes the rapid and sufficient desulfurization and slagging reaction in the molten pool, and the bed capacity is increased...

Embodiment 2

[0019] The side-blowing furnace in the copper smelting workshop of a smelting plant adopts the side-blowing jet spring type enhanced mixing method for smelting the molten pool, the diameter of the nozzle is reduced from 5cm to 2cm, the wind pressure is increased from 0.1MPa to 0.3MPa, and the outlet flow rate can reach 250m / s, to ensure that the oxygen-enriched air (the oxygen content in the oxygen-enriched air is 99.9wt%) is blown into the molten pool in the form of a jet. The downward inclination angle of the nozzle is set to 20°, which further enhances the lateral penetration depth of the gas jet, reduces the erosion and corrosion effect of the bubbles on the furnace wall, and increases the service life of the furnace wall from 1 year to 2 years. The gas rate and turbulent kinetic energy are increased by more than 20%, which promotes the rapid and sufficient desulfurization and slagging reaction in the molten pool, and the bed capacity is increased from 20t / m 2 ·d increase...

Embodiment 3

[0021] The side-blowing furnace in the copper smelting workshop of a smelting plant, after adopting the side-blowing jet spring type intensified mixing method for melting pool smelting, the diameter of the nozzle is reduced from 5cm to 1cm, the wind pressure is increased from 0.1MPa to 0.2MPa, and the outlet flow rate can reach 150m / s, to ensure that the oxygen-enriched air (the oxygen content in the oxygen-enriched air is 40wt%) is blown into the molten pool in the form of a jet. The downward inclination angle of the nozzle is set to 5°, which further enhances the lateral penetration depth of the gas jet, reduces the erosion and corrosion effect of the bubbles on the furnace wall, and increases the service life of the furnace wall from 1 year to 1.5 years. The gas rate and turbulent kinetic energy are increased by more than 20%, which promotes the rapid and sufficient desulfurization and slagging reaction in the molten pool, and the bed capacity is increased from 20t / m 2 ·d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com