Square cross flow cooling tower with single-side air intake

A cooling tower and cross-flow technology, which is applied in the field of cooling towers, can solve the problems of increasing the water supply of cooling towers, increasing power consumption, wasting water resources, etc., and achieves reduced fan energy consumption, high heat exchange efficiency, and improved ventilation conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the content of the present invention more comprehensible, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

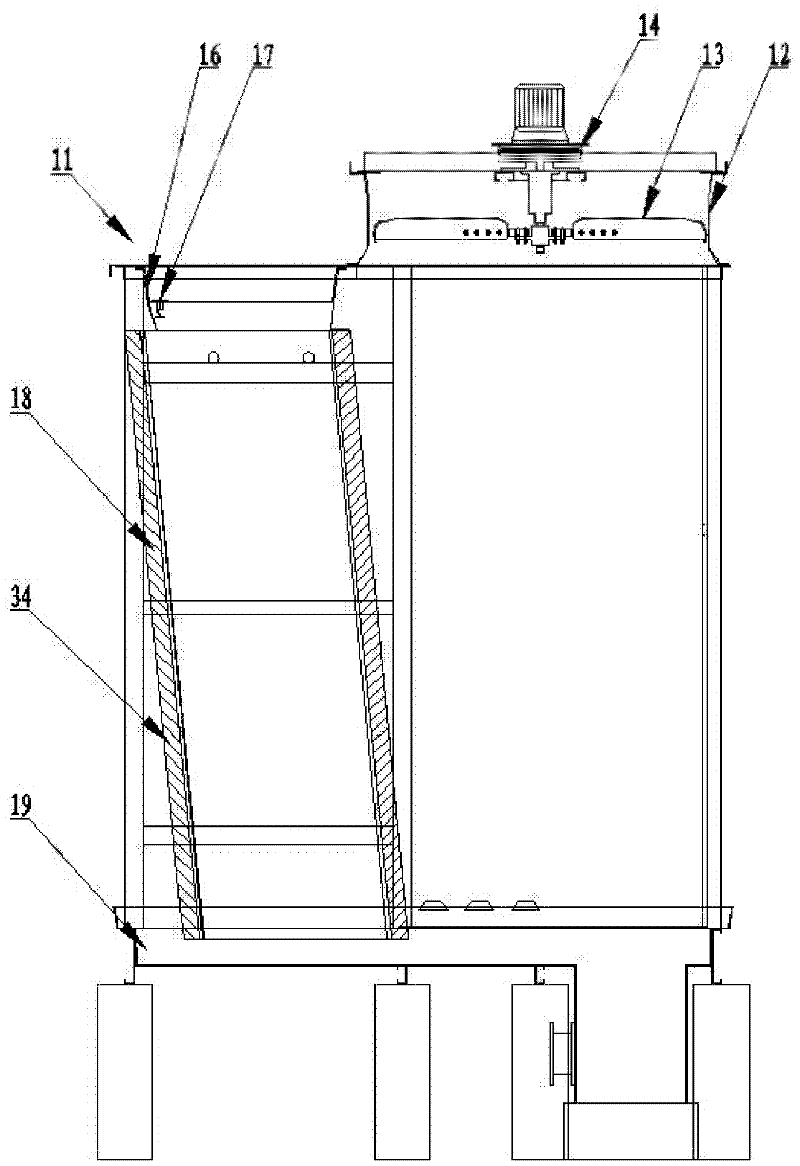

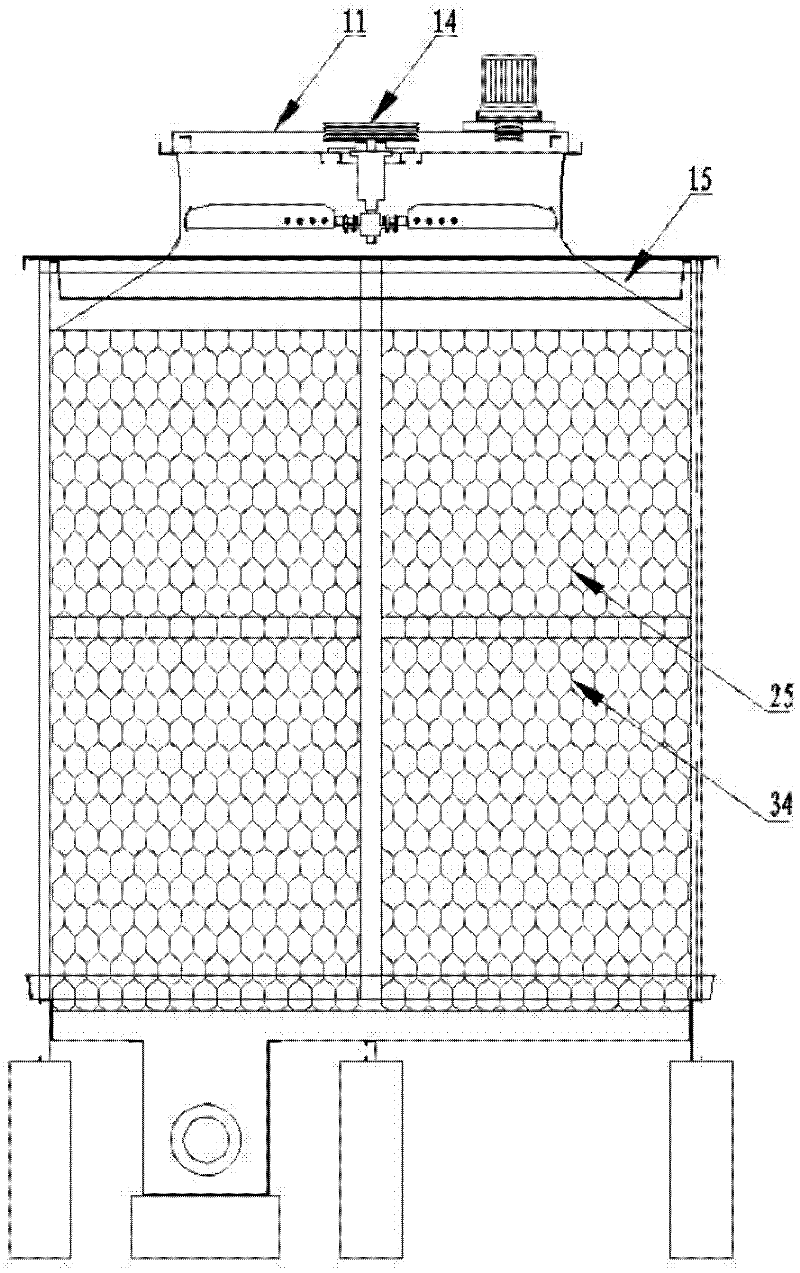

[0038] combine figure 1 and figure 2 As shown, the square single-sided wind-intake cross-flow cooling tower of the present invention comprises a frame 11, a side top of the frame 11 is provided with a blower 12, and a blower fan 13 is arranged in the blower 12; the other side of the frame 11 There is a water shower device inside, and the water shower device 18 is composed of a water shower basin 16, a water distribution nozzle 17, a water shower filler 18 and a water collection basin 19; the water shower basin 16 is located above the water shower filler 18, and the water distribution nozzle 17 is installed In the water shower basin 16; the water collection basin 19 is located below the water shower filler 18;

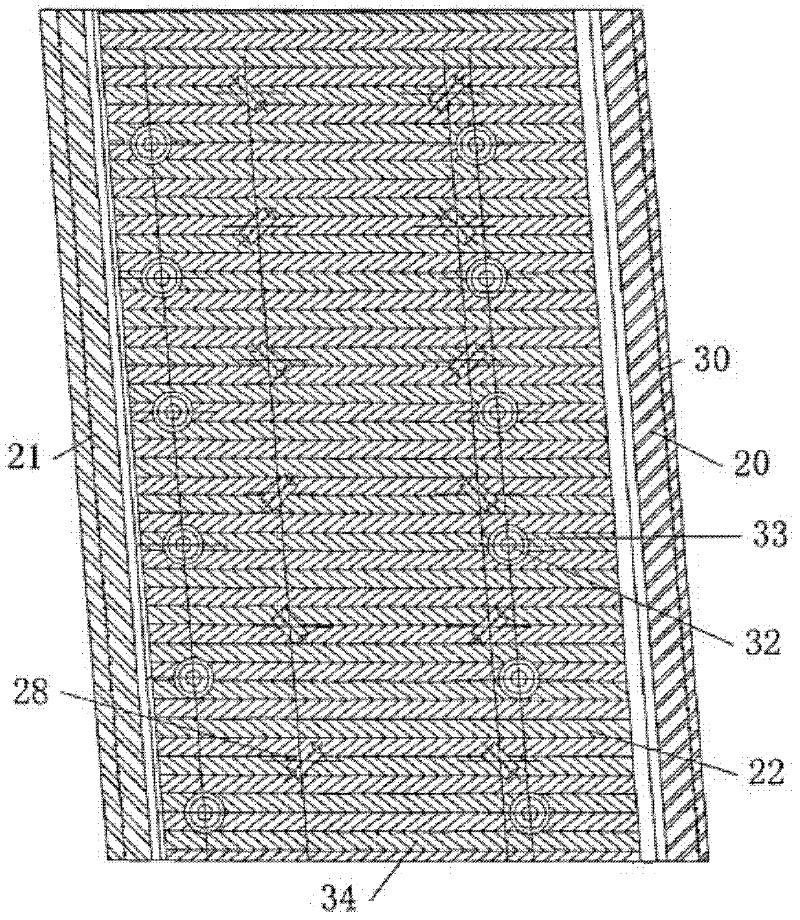

[0039] The water spray filler 18 is composed of a plurality of stacked f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com