Hollow metal material preparing device and method

A technology for metal materials and preparation devices, which is applied in metal processing equipment, transportation and packaging to achieve the effects of high energy absorption, good impact resistance and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

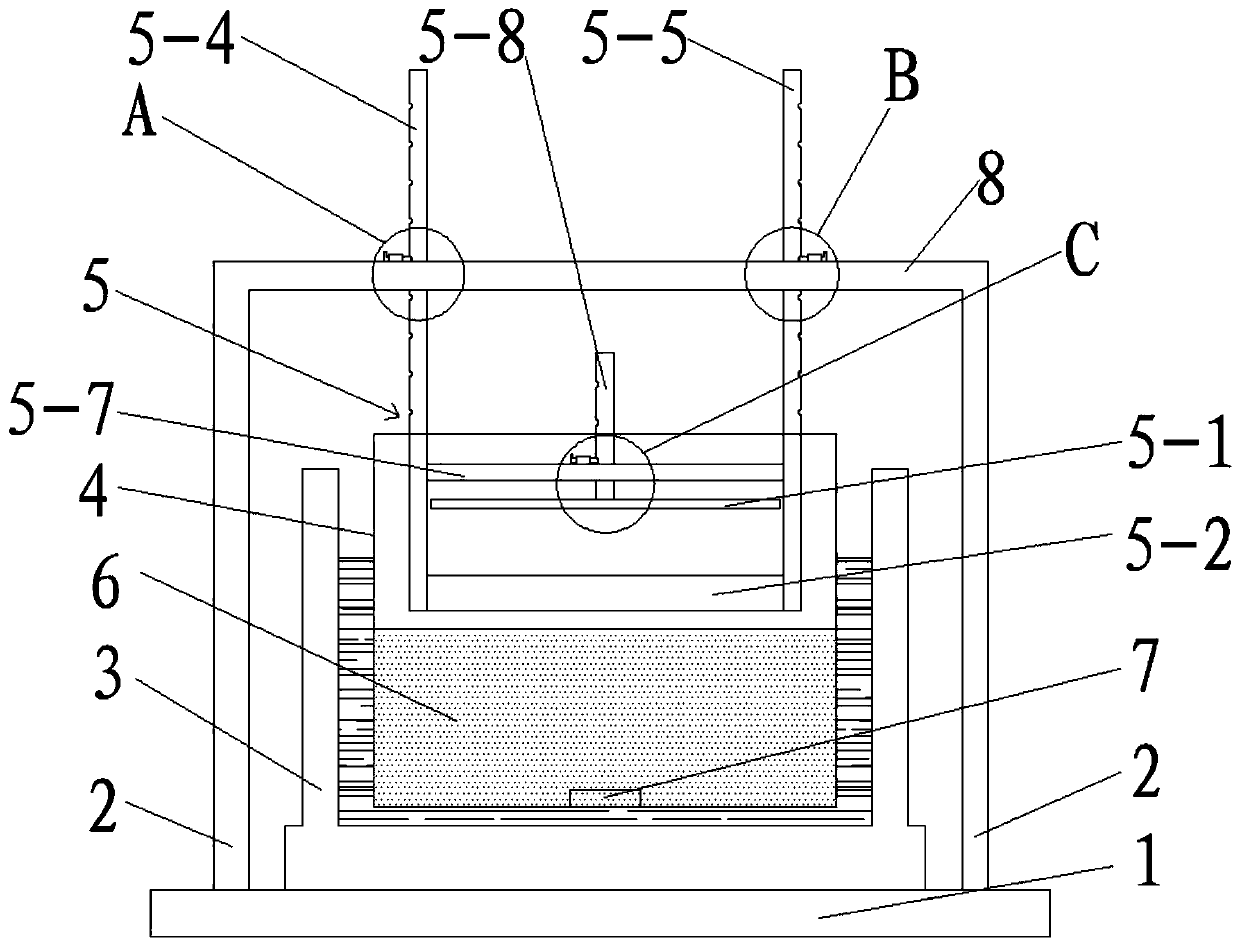

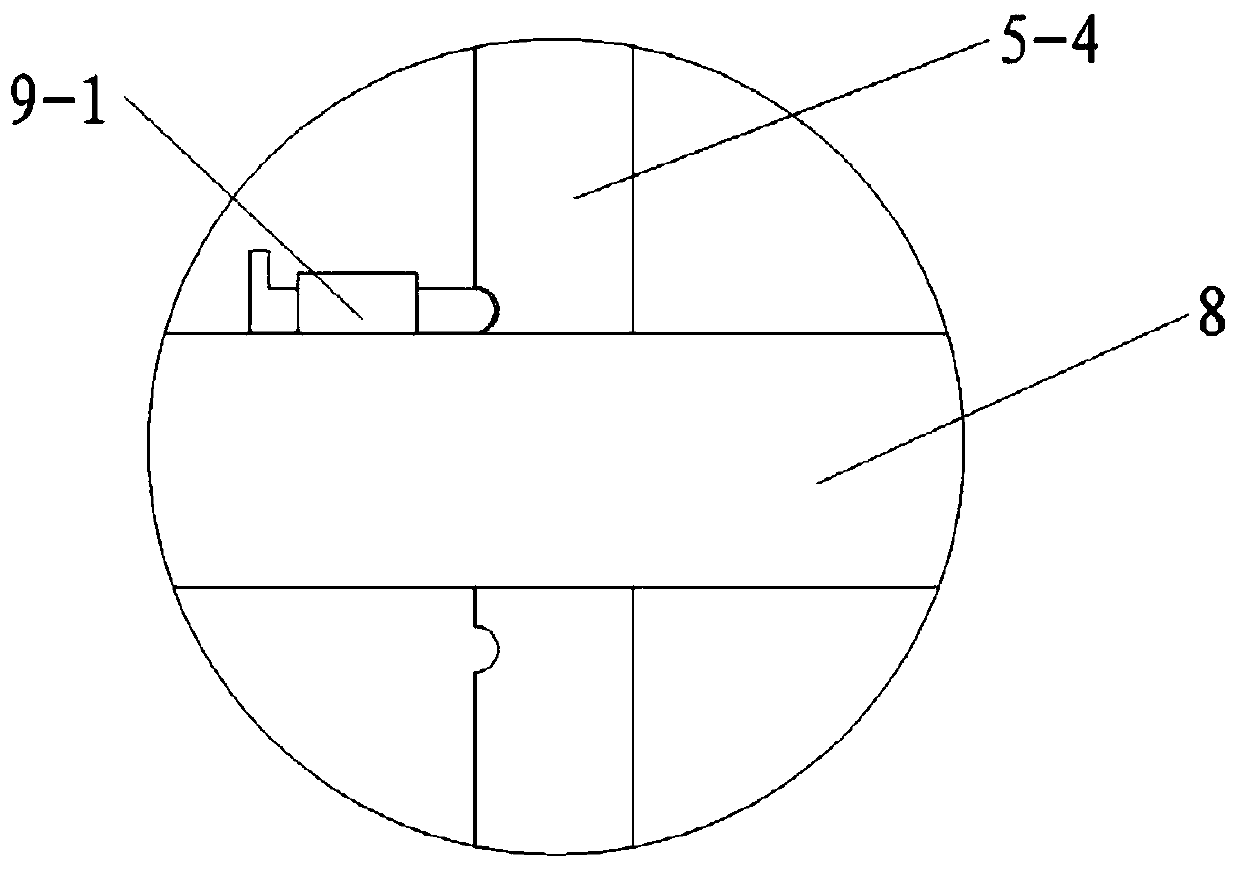

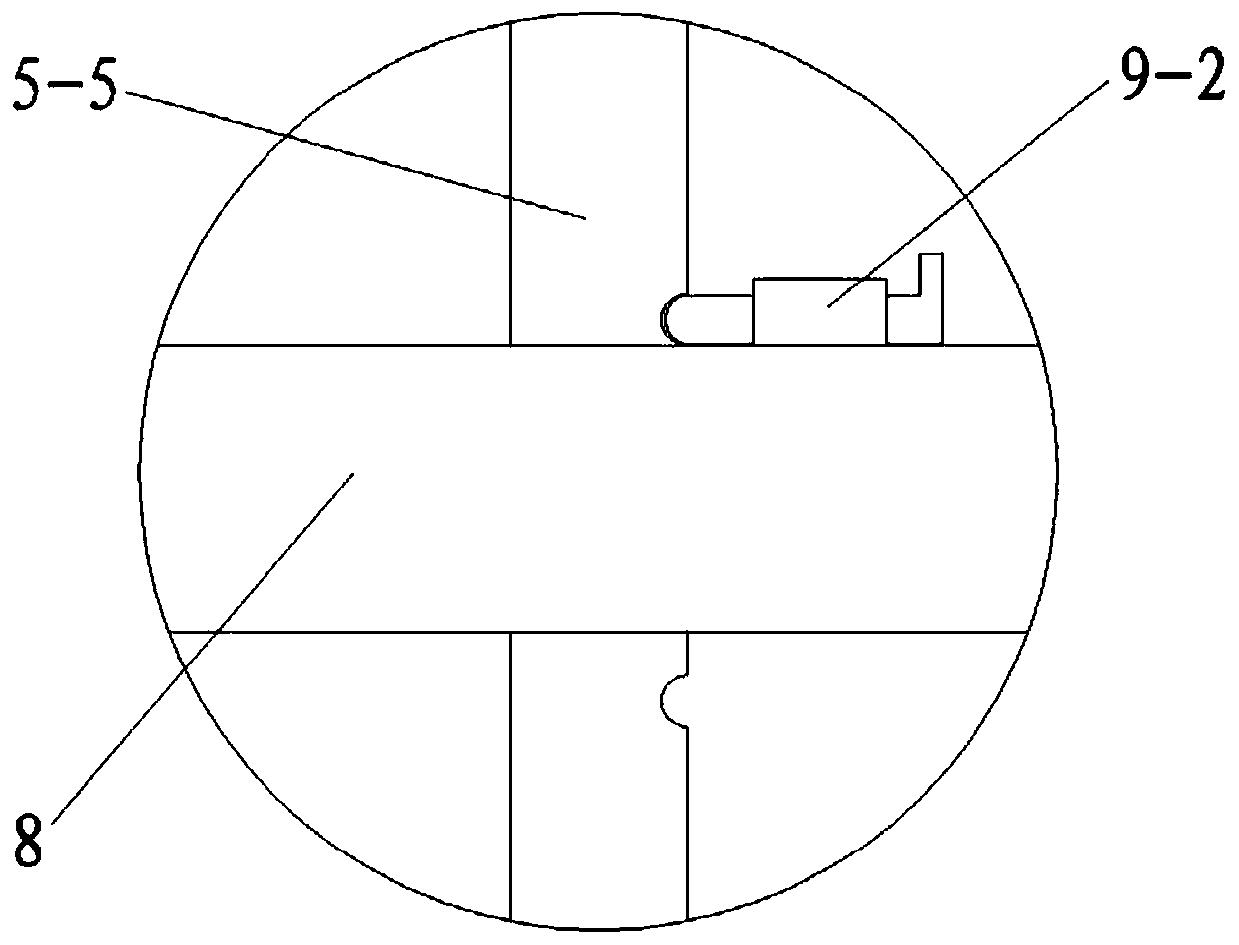

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the preparation device of the hollow metal material of the present invention includes a workbench 1 and a fixed frame arranged on the workbench 1, and the fixed frame is fixed by two columns 2 symmetrically arranged at two ends of the workbench 1 and The first beam 8 connected between the two columns 2 is composed of a magnetic stirring water bath 3 placed in the inner cavity of the fixed frame, a slurry container 4 is arranged in the magnetic stirring water bath 3, and the slurry A dipping basket 5 is arranged in the container 4, and the dipping basket 5 includes a basket frame 5-2 and a porous bottom plate 5-3 fixedly connected with the basket frame 5-2, and the outside wall of the basket frame 5-2 is symmetrical A first pull rod 5-4 and a second pull rod 5-5 are provided, a porous cover plate 5-1 is provided on the basket frame 5-2, and the porous cover plate 5-1 and the porous bottom pla...

Embodiment 2

[0050] This embodiment includes the following steps:

[0051] Step 1. Lift the dipping basket 5 and fix it with the first pin 9-1 and the second pin 9-2, add the pre-treated slurry into the slurry container 4 and perform stirring treatment, and then place the porous cover plate 5- 1 After lifting, put the inner support body on the porous bottom plate 5-3 in the dipping basket 5, lower the porous cover plate 5-1 to cover the basket frame 5-2, and fix it with the third pin 5-6, Open the first plug 9-1 and the second plug 9-2 to lower the dipping basket 5 until the inner support is completely submerged in the pretreatment slurry for dipping, and then lift the dipping basket 5 until it is separated from the pretreatment slurry One pin 9-1 and the second pin 9-2 are fixed, after the excess pretreatment slurry in the impregnation basket 5 is completely discharged, the first pin 9-1 and the second pin 9-2 are opened to move the impregnation basket 5 from the first The crossbeam 8 is...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] Step 1. Lift the dipping basket 5 and fix it with the first pin 9-1 and the second pin 9-2, add the pre-treated slurry into the slurry container 4 and perform stirring treatment, and then place the porous cover plate 5- 1 After lifting, put the inner support body on the porous bottom plate 5-3 in the dipping basket 5, lower the porous cover plate 5-1 to cover the basket frame 5-2, and fix it with the third pin 5-6, Open the first plug 9-1 and the second plug 9-2 to lower the dipping basket 5 until the inner support is completely submerged in the pretreatment slurry for dipping, and then lift the dipping basket 5 until it is separated from the pretreatment slurry One pin 9-1 and the second pin 9-2 are fixed, after the excess pretreatment slurry in the impregnation basket 5 is completely discharged, the first pin 9-1 and the second pin 9-2 are opened to move the impregnation basket 5 from the first The crossbeam 8 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com