Feed cutter for feed puffing device

A technology of extruding device and feed, applied in feed, application, food science and other directions, can solve problems such as operator injury, cutter wear, easy aging, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

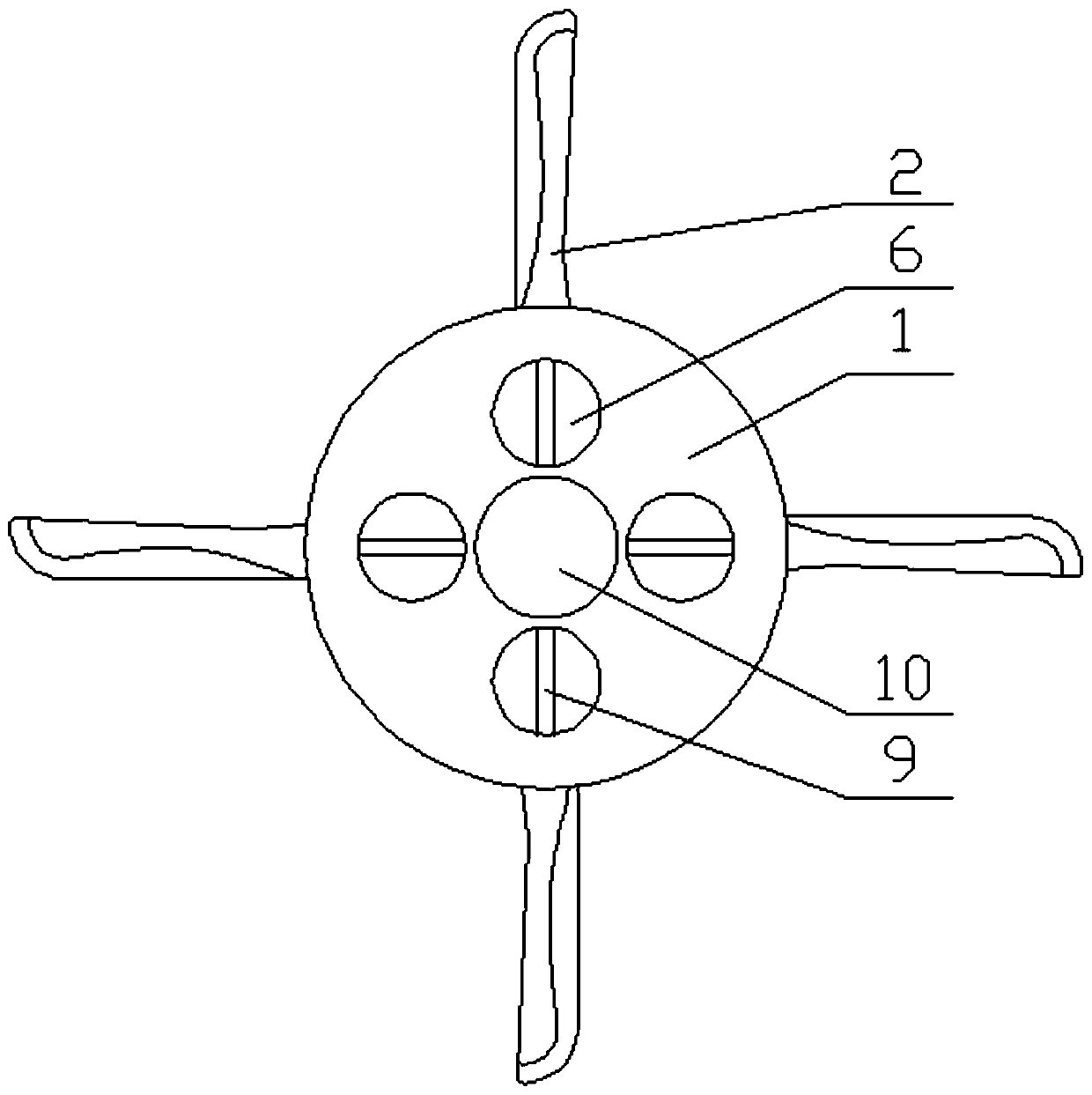

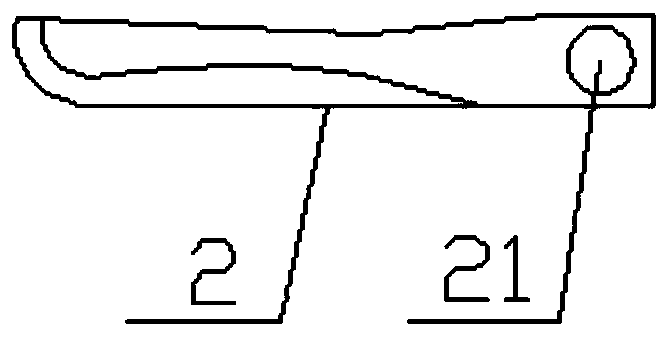

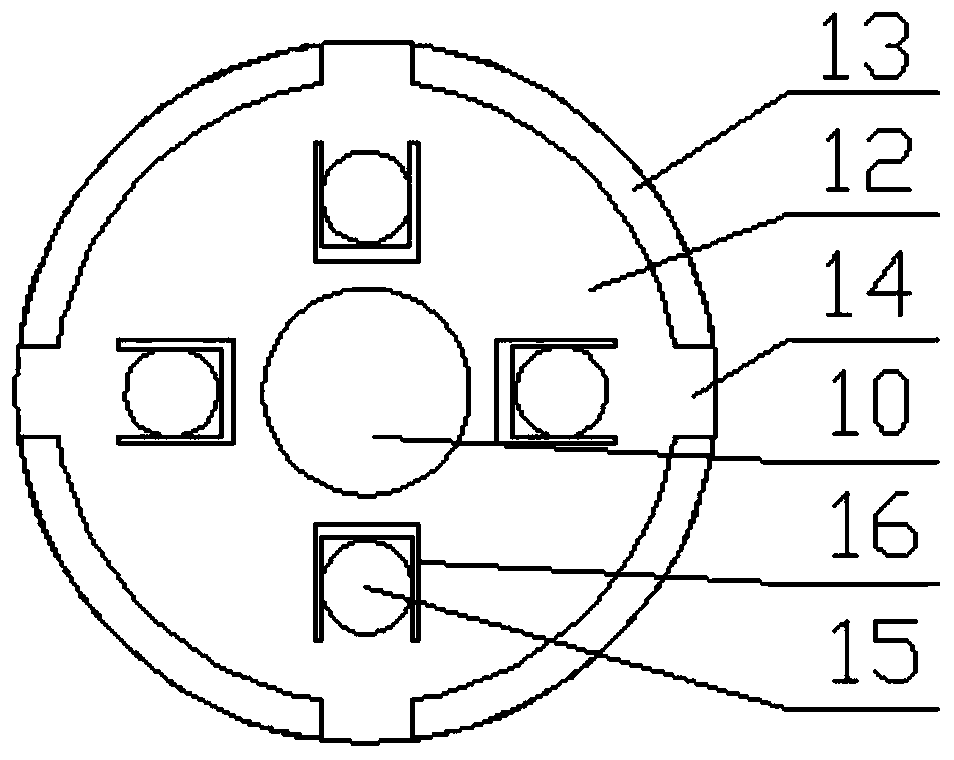

[0032] Such as figure 1 The shown feed cutter for a feed puffing device includes a circular cutter head 1 and at least two cutter heads 2 (generally four cutter heads 2) that are detachably mounted on the cutter head 1, such as figure 2 As shown, the mounting end of the cutter head 2 is provided with a mounting hole 21; Figure 5 and Figure 7 As shown in (a), the cutter head 1 includes an upper top plate 11 and a lower bottom plate 12 clamped on the upper and lower sides of the cutter head 2,

[0033] Combine below Figure 7 (b), Figure 7 (c), Figure 7 (d), Figure 8 and Picture 9 analysis,

[0034] Such as image 3 As shown, the peripheral edge of the lower base plate 12 is evenly provided with side barriers 13 corresponding to the cutter head 2 one-to-one, and a socket 14 is formed between every two adjacent side barriers 13 for the cutter head 2 to insert. Such as Figure 5 As shown, the upper top plate 11 is fixed on the top of the side rail 13, as image 3 As shown, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com