Method for preparing graphene by electrochemically expanding intercalated graphite

A technology of intercalated graphite and expanded graphite, which is applied in the field of graphene, can solve the problems that intercalated graphite affects the quality consistency of final products, the structure of graphite sheets is damaged, and the utilization rate of reaction raw materials is low, so as to achieve easy industrial use and consistent quality Good performance and stable storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

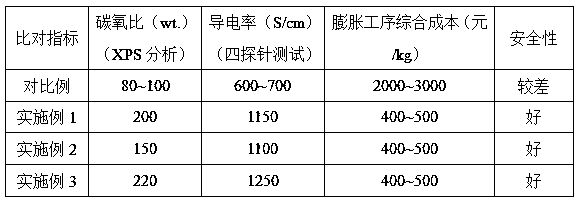

Embodiment 1

[0027] This embodiment discloses a method for preparing graphene from electrochemically expanded intercalated graphite, the specific process of which is:

[0028] (1) First prepare paraffin wax and ferric chloride intercalated graphite, the mass ratio of paraffin wax and ferric chloride intercalated graphite is 1:10, after preparing the materials, melt the paraffin wax into a molten state, and add the intercalated graphite into the molten paraffin wax for Kneading, after kneading evenly, take out the mixture while it is hot and place it in a mold, and use a tablet press to press the mixture into a thick sheet to obtain an intercalated graphite electrode, which can be used after cooling.

[0029] (2) The intercalated graphite electrode is used as the cathode, the graphite plate is used as the anode, and the alkaline aqueous solution is used as the electrolyte, and a DC voltage of 3-15V is applied to prepare expanded graphite. Wherein, the electrolyte is a mixture of sodium hydr...

Embodiment 2

[0032] This embodiment discloses a method for preparing graphene from electrochemically expanded intercalated graphite, the specific process of which is:

[0033] (1) Prepare paraffin wax and ferric chloride intercalated graphite first, the mass ratio of paraffin wax and ferric chloride intercalated graphite is 1: 150, after preparing the materials, melt the paraffin wax into a molten state, and add the intercalated graphite into the molten paraffin wax for Kneading, after kneading evenly, take out the mixture while it is hot and place it in a mold, and use a tablet press to press the mixture into a thick sheet to obtain an intercalated graphite electrode, which can be used after cooling.

[0034] (2) The intercalated graphite electrode is used as the cathode, the graphite plate is used as the anode, and the alkaline aqueous solution is used as the electrolyte, and a DC voltage of 3-15V is applied to prepare expanded graphite. Wherein, the electrolyte is a mixture of sodium hy...

Embodiment 3

[0037] This embodiment discloses a method for preparing graphene from electrochemically expanded intercalated graphite, the specific process of which is:

[0038] (1) First prepare paraffin wax and ferric chloride intercalated graphite, the mass ratio of paraffin wax and ferric chloride intercalated graphite is 1:80, after preparing the materials, melt the paraffin wax into a molten state, and add the intercalated graphite into the molten paraffin wax for Kneading, after kneading evenly, take out the mixture while it is hot and place it in a mold, and use a tablet press to press the mixture into a thick sheet to obtain an intercalated graphite electrode, which can be used after cooling.

[0039] (2) The intercalated graphite electrode is used as the cathode, the graphite plate is used as the anode, and the alkaline aqueous solution is used as the electrolyte, and a DC voltage of 3-15V is applied to prepare expanded graphite. Wherein, the electrolyte is a mixture of sodium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com