Granulated salt and special mold thereof

A granulation and weight technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of low hardness, high pulverization rate, and low yield, and achieve the effect of full granules and small flash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

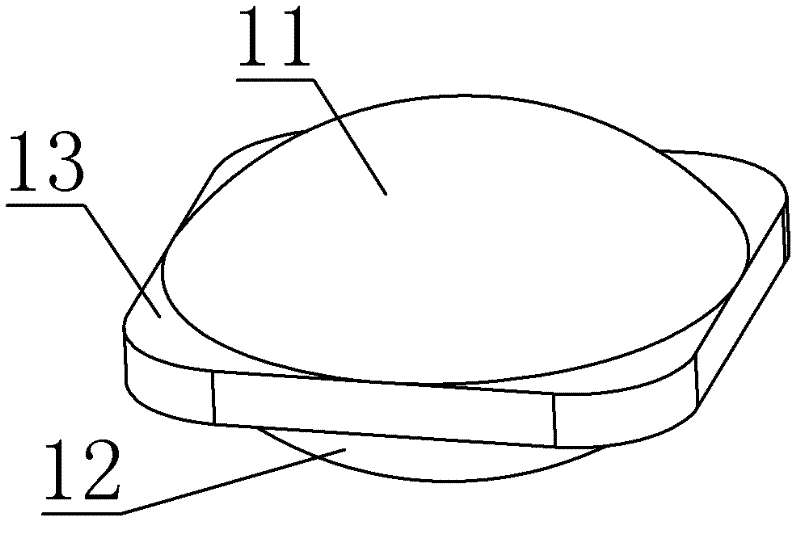

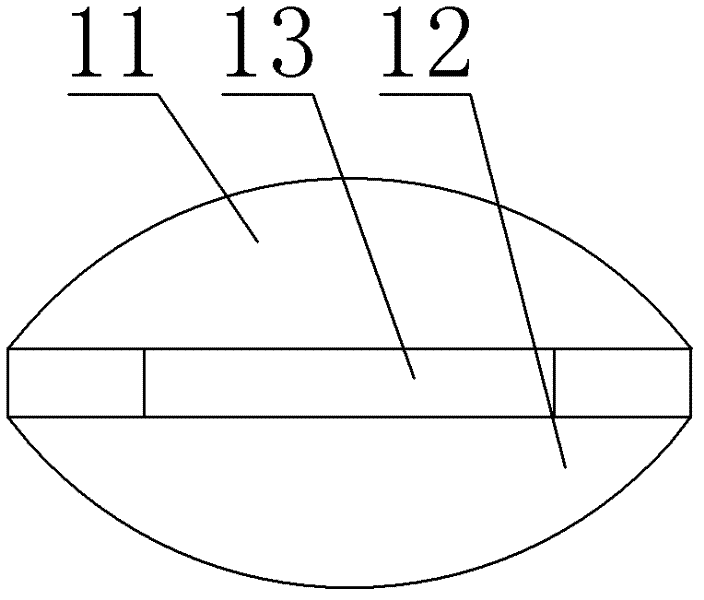

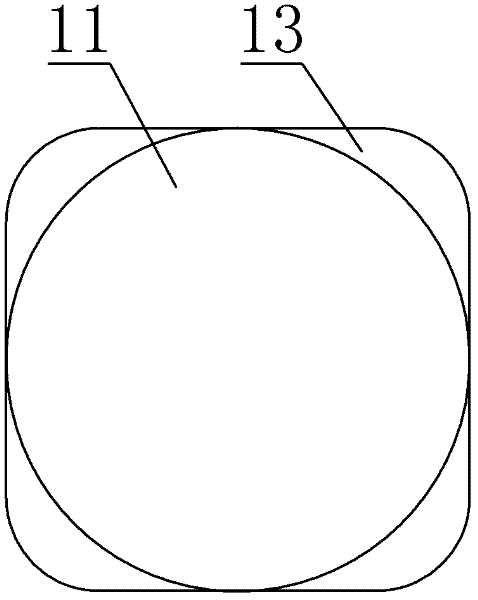

[0031] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0032] figure 1 figure 2 image 3 It is the first embodiment of a kind of granulated salt of the present invention, and described granulated salt adds 0.1~0.2% by weight of sodium citrate and 0.02~0.03% by weight of dedecylphenoxyether to sodium chloride Sodium diphenylsulfonate, the moisture content of finished product is 0.5~1.5%; Comprising upper spherical crown 11 and lower spherical crown 12, there is process section 13 between upper and lower spherical crown 11,12, and the cross-sectional shape of process section 13 is The four corners of the process section 13 are square, and the four corners of the process section 13 have circular arc transition se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com