A double-head chamfering grinding device for permanent magnet ferrite

A permanent magnet ferrite and chamfering technology, which is applied in the direction of grinding/polishing safety devices, grinding slides, grinding racks, etc. Oxygen body yield rate decline and other problems, to achieve the effect of high yield rate, chamfering yield rate, chamfering processing precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

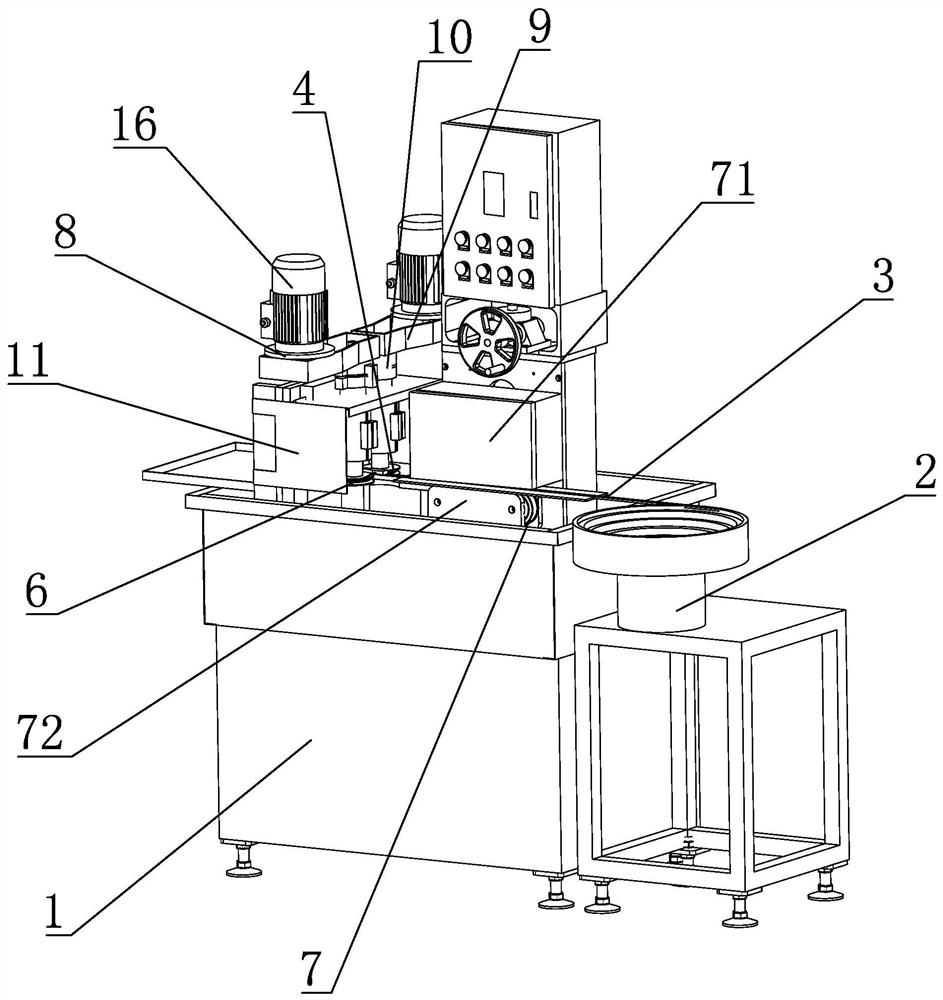

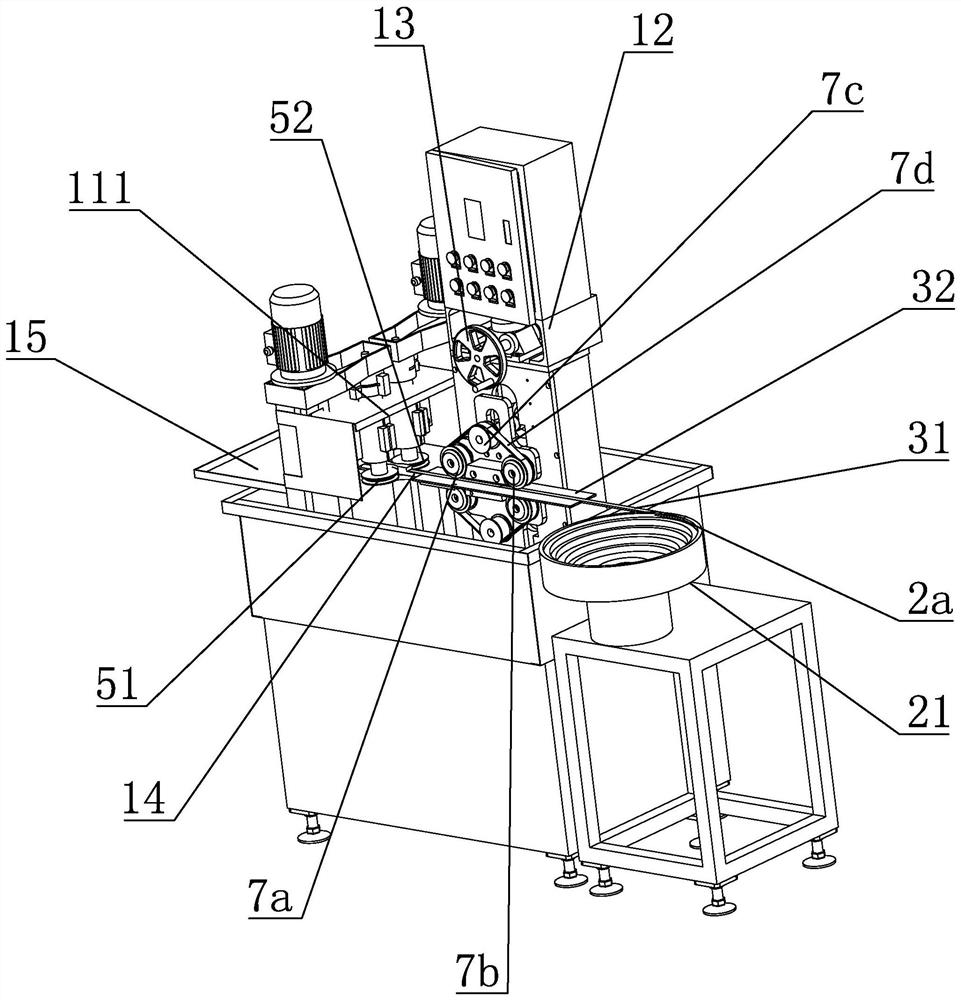

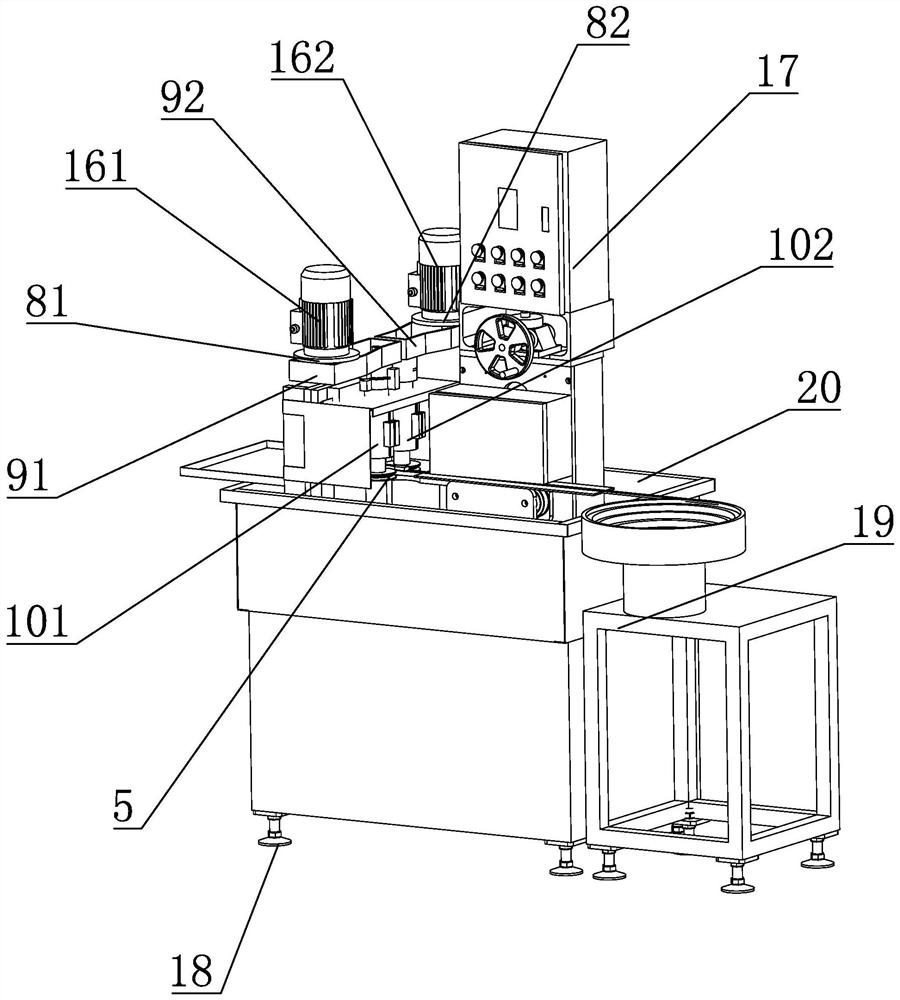

[0036] Such as Figure 1 to Figure 3 As shown, a permanent magnet ferrite double-head chamfering grinding device includes a frame 1, a feeding mechanism 2 is provided on one side of the frame, a conveying member 3 and a chamfering member 4 are arranged on the frame, and the chamfering member Including the forming grinding wheel 5 arranged in gaps, the forming grinding wheel rotates synchronously under the drive of the driving member, the feeding mechanism aligns the permanent magnet ferrite 6 and then transports it to the conveying member, and when the permanent magnet ferrite is conveyed to the chamfering member by the conveying member The forming grinding wheel chamfers the two ends of the permanent magnet ferrite. The frame is equipped with a horizontal pushing member 7 that drives the adjacent permanent magnet ferrite to fit closely. The first transverse pusher member 71 and the second transverse pusher member 72 on both sides; the multi-groove pulley 8 driven by the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com