Ultrasonic vibration chamfering device applied to complex curved surface

A technology of ultrasonic vibration and chamfering device, which is applied in the field of coating material cutting processing and coating material cutting equipment components, can solve the problems of limiting the application range of vibration processing, improve load capacity and stability, reduce heat generation, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

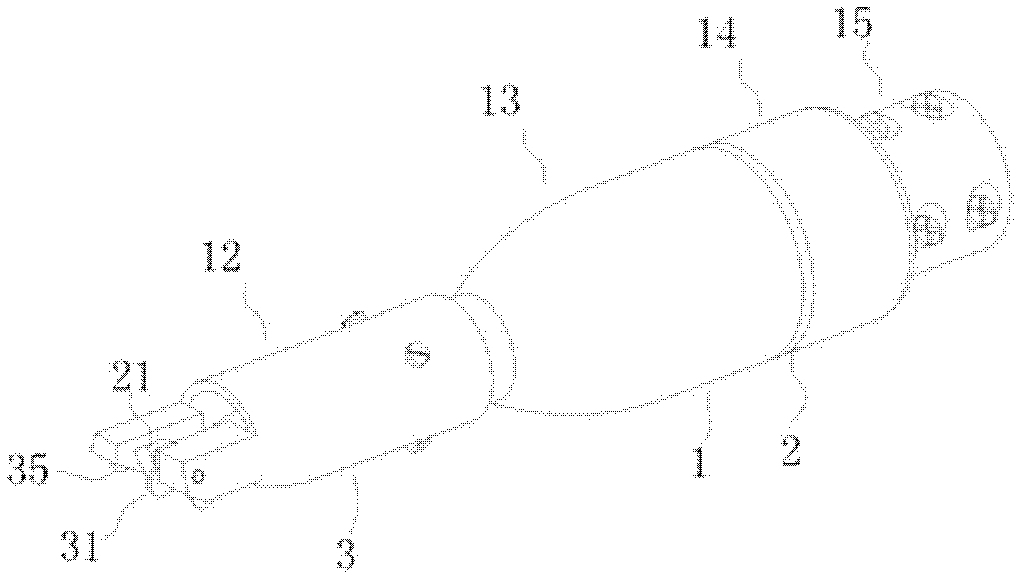

[0023] See figure 1 As shown, the present invention is an ultrasonic vibration chamfering device applied to complex curved surfaces, which is composed of a shell component 1 , an ultrasonic vibration component 2 , and a positioning support component 3 . The position connection relationship between them is: the positioning support component 3 is installed outside the shell component 1 , and the ultrasonic vibration component 2 is installed inside the shell component 1 .

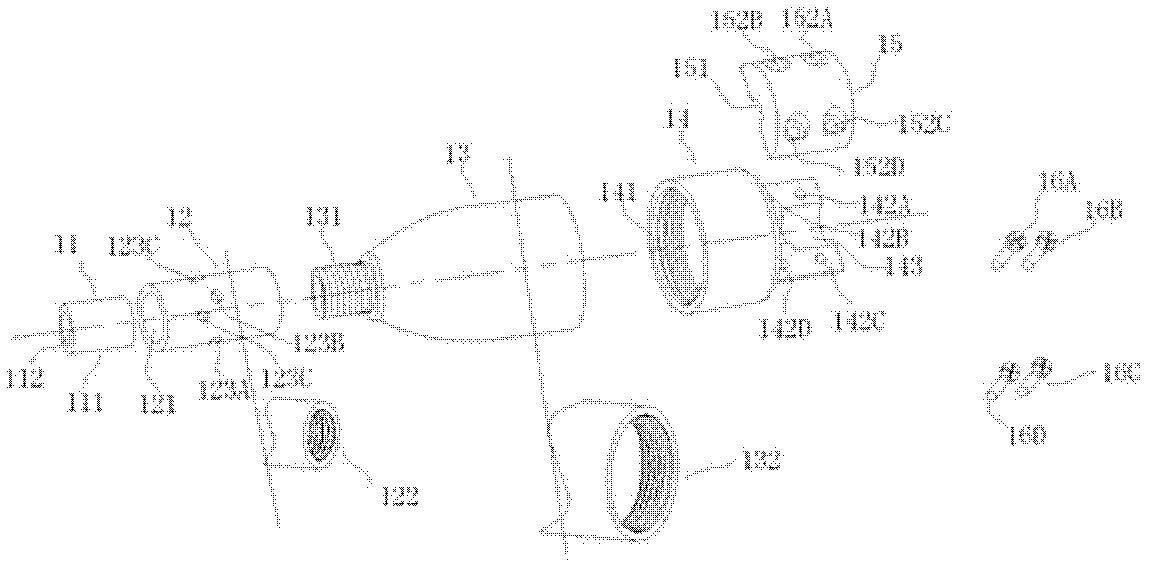

[0024] The housing assembly 1 see figure 2 , image 3 , consists of bushing 11, front outer cylinder 12, middle outer cylinder 13, rear outer cylinder 14, cable pressing piece 15 and compression bolts 16A, 16B, 16C, 16D. The shell assembly 1 is sequentially arranged as an assembly 1 along the longitudinal axis, including a bushing 11, a front outer cylinder 12, a middle outer cylinder 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com