Metering, testing and control method for internal pressure reduction flowing characteristic of labyrinth disc pressure reducing valve

A measurement test and flow characteristic technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problems of regulation lag, low control accuracy, lack of quantitative measurement test methods for depressurized flow characteristics, etc. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

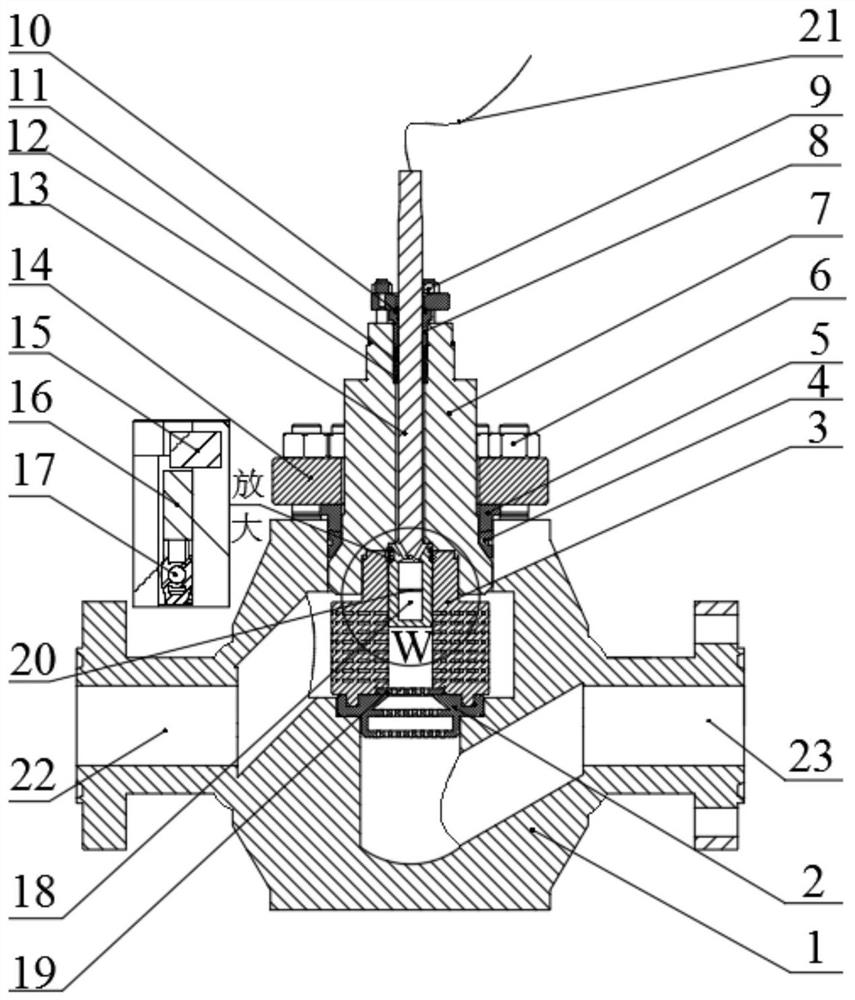

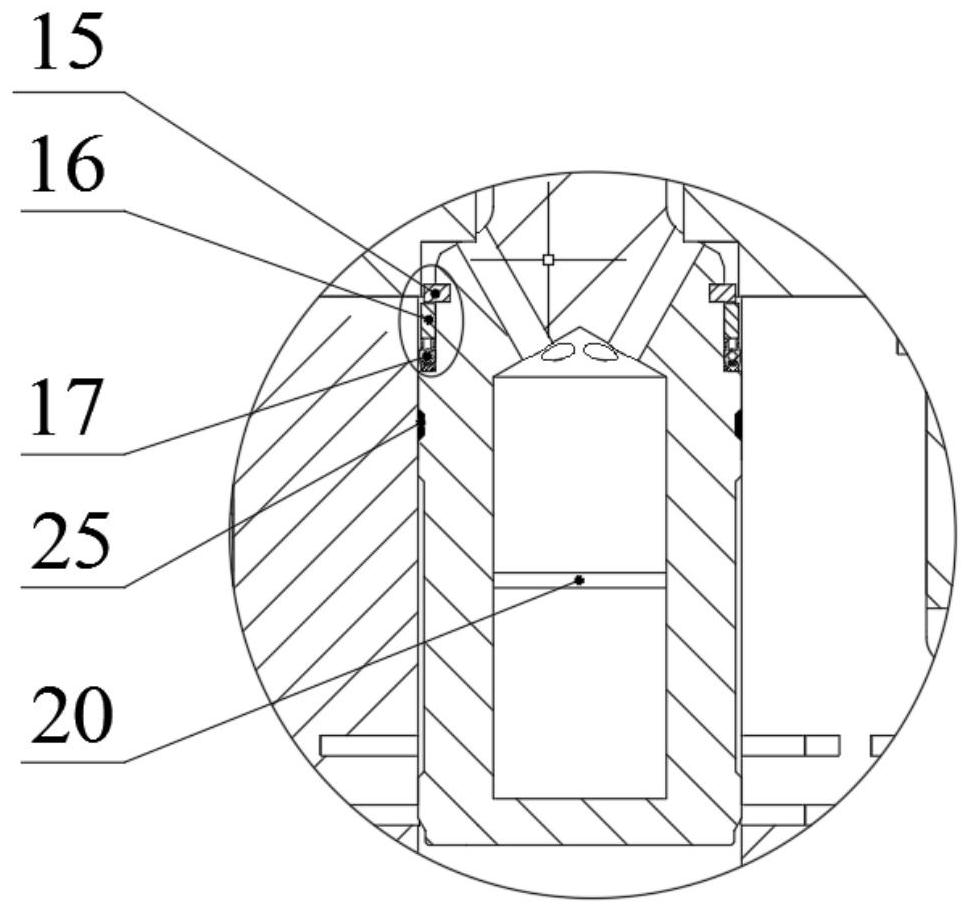

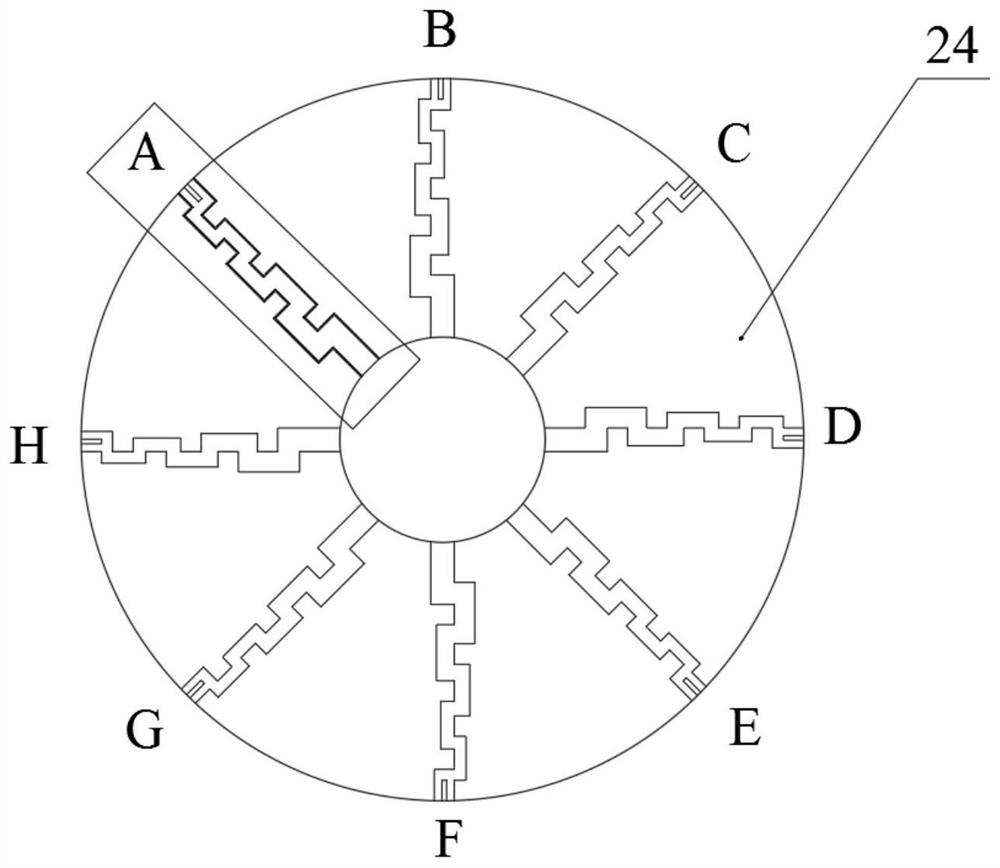

[0047] Such as figure 1 , figure 2 As shown, the specific implementation of the labyrinth disc pressure reducing valve includes a valve body 1, a valve seat 2, a labyrinth disc sleeve 3, a valve cover 7, a valve stem 13, a valve core 18, a throttle orifice 19 and a valve stem position regulator 21. A circular opening is set on the top of the valve body 1, and a valve cover 7 is installed in the circular opening. A central through hole is opened in the vertical direction inside the valve cover 7. An upper cavity and a lower cavity are provided inside the valve body. There is a horizontal medium inlet 22 and a medium outlet 23 at the side end, the medium inlet 22 communicates with the upper cavity of the valve body 1, and the medium outlet 23 communicates with the lower cavity of the valve body 1; The hole is connected, and the valve seat 2 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com