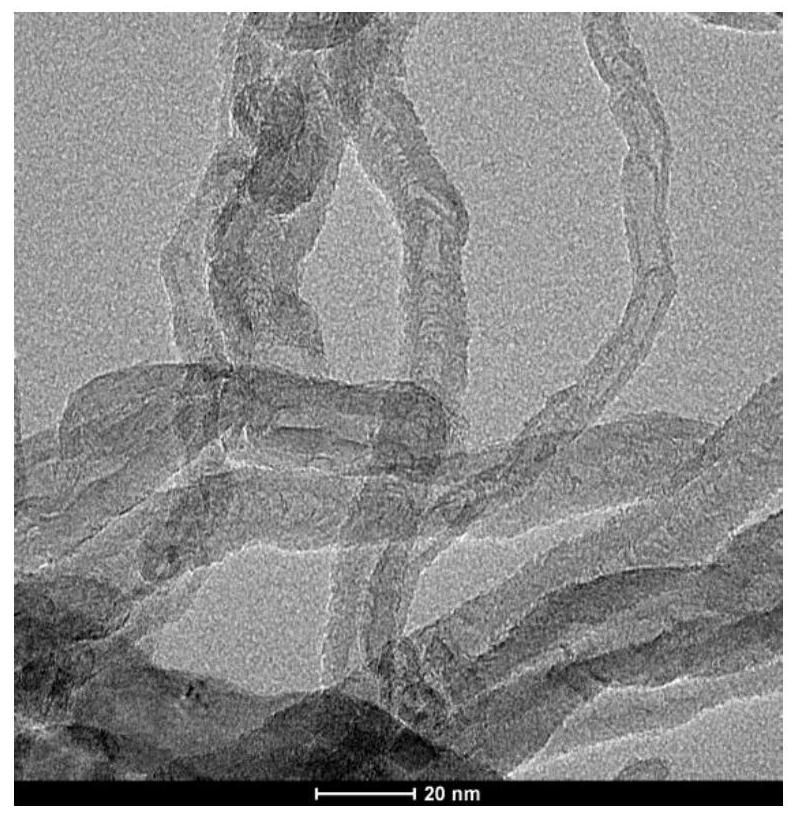

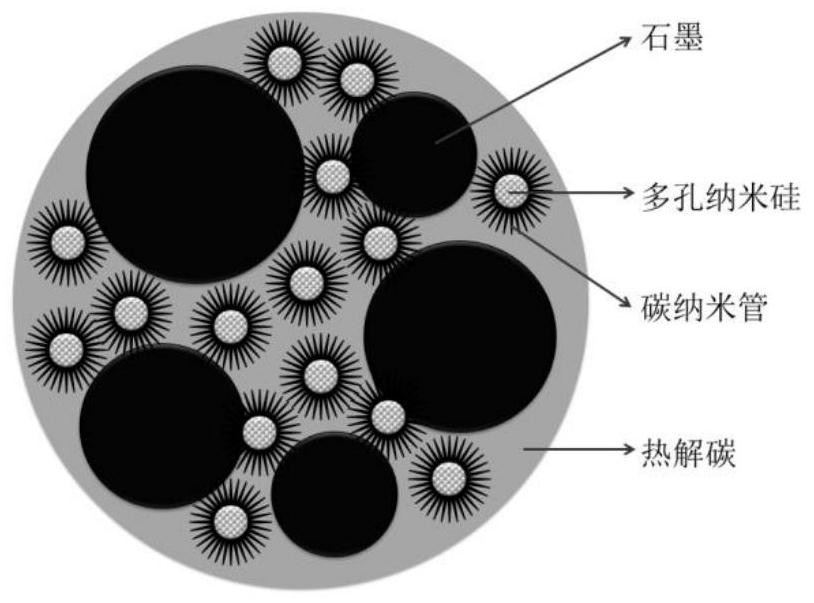

A si/cnt/graphite@c composite silicon-carbon anode material and its preparation and application

A negative electrode material, graphite technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, silicon, etc., can solve problems such as unsatisfactory performance and chemical performance, and achieve excellent electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] 1 take 0.05gAgno 3 In an HF solution dissolved in a 50 ml concentration of 10 m, 1 g Nano-silica particles were added to the mixture and stirred for 0.5 h, and 10 ml of oxygen (30% h) was added. 2 O 2 The aqueous solution was continued for 1 h, filtered, washed, and dried in an oven at 120 ° C;

[0086] 2 The obtained porous silicon (0.8 g), 0.05 g of cobalt chloride was added to 20 ml of water, 10 ml of ethanol, stirred and dissolved, dried in an oven at 80 ° C;

[0087] 3 The resulting material (0.85 g), ball-type graphite (0.5 g), polyvinylidene fluoride (0.05 g), 0.2 g asphalt was placed in a mixer, and the mixed material was supplied into the kneader. Perform granulation;

[0088] 4 Place the material from the upper step in a nitrogen gas, vacuum, retaining the inner pressure 200Pa, heat treatment, the heat treatment temperature is 750 ° C, the holding time is 2 h;

[0089] 5 Place the above-processed material in a hydrogen gas, heat treatment under normal pressure con...

Embodiment 2

[0094] 1 take 0.05gAgno 3 In an HF solution dissolved in a 50 ml concentration of 10 m, 1 g Nano-silica particles were added to the mixture and stirred for 0.5 h, and 10 ml of oxygen (30% h) was added. 2 O 2 The aqueous solution was continued for 1 h, filtered, washed, and dried in an oven at 120 ° C;

[0095] 2 The obtained porous silicon (0.75 g; porosity is 22%), 0.1 g of iron nitrate is added to 20 ml of water, and after stirring, drying is dried in an oven at 80 ° C;

[0096] 3 The resulting material (0.85 g), petroleum coke (2 g), polypropylene (0.05 g), 0.2 g of phenolic resin were placed in the mixer, and the mixed material was supplied into the kneading machine and granulated ;

[0097] 4 Place the above-off material in a nitrogen atmosphere, vacuum, retain the inner pressure 500Pa, heat treatment, heat treatment temperature is 800 ° C, the holding time is 3 h;

[0098] 5 Place the above-proceeded material in a hydrogen gas, heat treatment under normal pressure conditions...

Embodiment 3

[0103] 1 take 0.05gAgno 3 In an HF solution dissolved in a 50 ml concentration of 10 m, 1 g Nano-silica particles were added to the mixture and stirred for 0.5 h, and 10 ml of oxygen (30% h) was added. 2 O 2 The aqueous solution was stirred for 1 h, filtered, washed, and dried in an oven at 120 ° C.

[0104] 2 The obtained porous silicon (0.85 g), 0.1 g of oxalate is added to 20 ml of water, and after stirring, drying is dried in an oven at 80 ° C;

[0105] 3 The resulting material, natural graphite (2 g), sodium alginate (0.05 g), 0.2 g of glucose were placed in a mixing machine, and the mixed material was supplied into the kneading machine and granulated;

[0106] 4 Place the above-off material in a nitrogen atmosphere, vacuum, retain the inner pressure 200Pa, heat treatment, heat treatment temperature is 600 ° C, the holding time is 4 h;

[0107] 5 Place the above-processed material in the hydrogen gas, heat treatment under normal pressure conditions, the heat treatment tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com