A modular eddy-current brake device

An eddy current braking, modular technology, applied in the field of transportation, can solve the problems of hidden safety hazards, mobile equipment detachment, large replacement time and economic cost, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

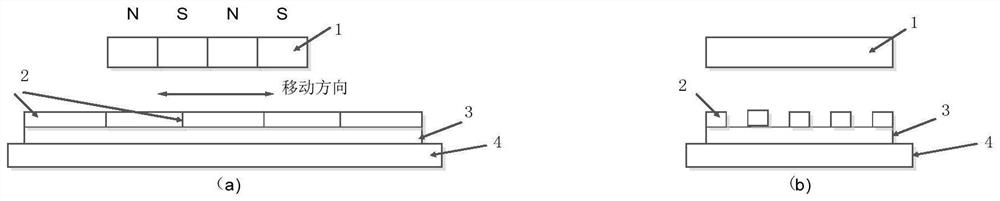

[0025] Such as figure 1 as shown, figure 1 Middle (a) is a longitudinal schematic diagram of the modular eddy current braking device, figure 1 Middle (b) is a transverse schematic diagram of a modularized eddy current braking device. It can be seen from the figure that the modularized eddy current braking device includes a moving magnetic component 1 and a stationary eddy current reaction component, and the magnetic component 1 and the eddy current response component are arranged oppositely. The magnetic component 1 includes a plurality of N and S magnetic poles arranged alternately, the magnetic poles are permanent magnets, and the magnetic component 1 should at least form 1 N pole and 1 S pole ( figure 1 In the middle are 2 N poles and 2 S poles). The sequence of N and S pole arrangement is irrelevant, it can be as follows figure 1 The first pole shown is an N pole, and the first magnetic pole may also be an S pole. The arrangement of the magnetic components 1 may also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com