An automatic oil scraping and discharging device for a cold rolling mill

A technology of discharging device and oil scraping device, which is applied in workpiece cleaning device, metal rolling, metal rolling, etc., can solve the problem of poor oil scraping effect of steel pipes, and achieve good oil scraping effect and strong automatic recovery ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

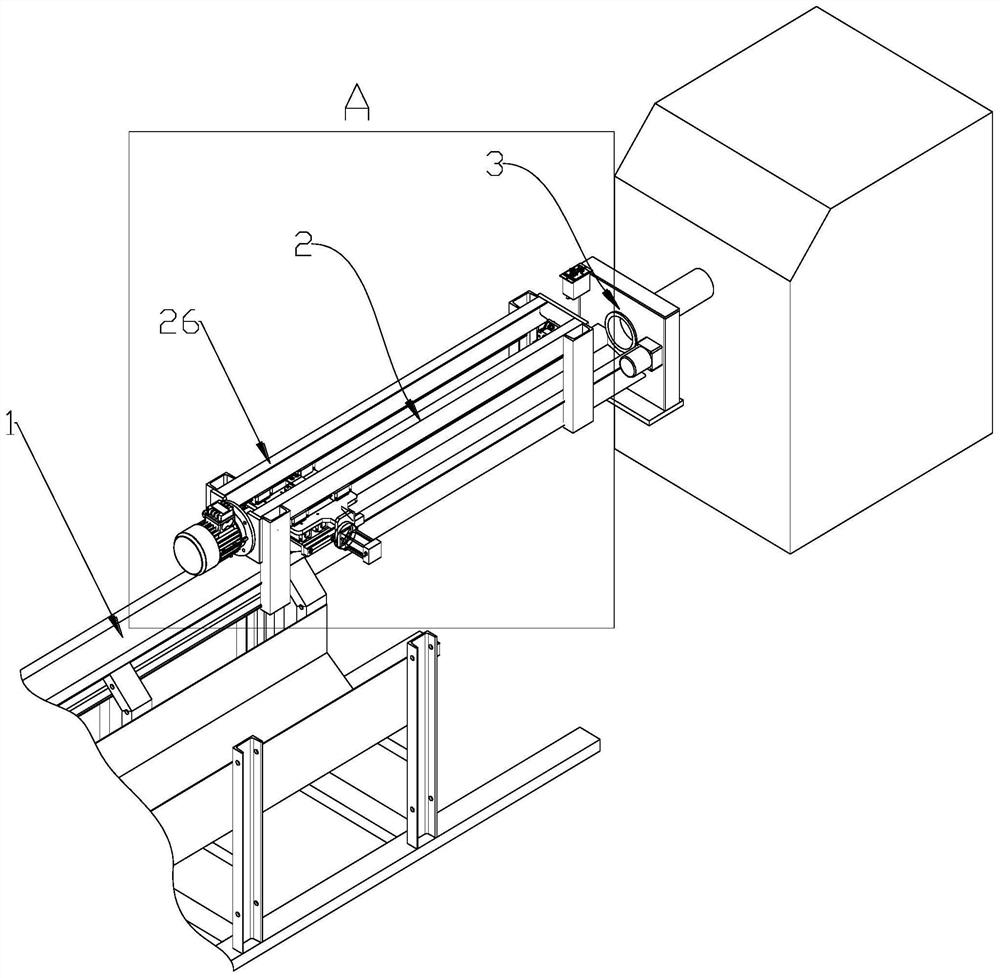

[0063] As shown in FIG. 1 to FIG. 3, this embodiment proposes

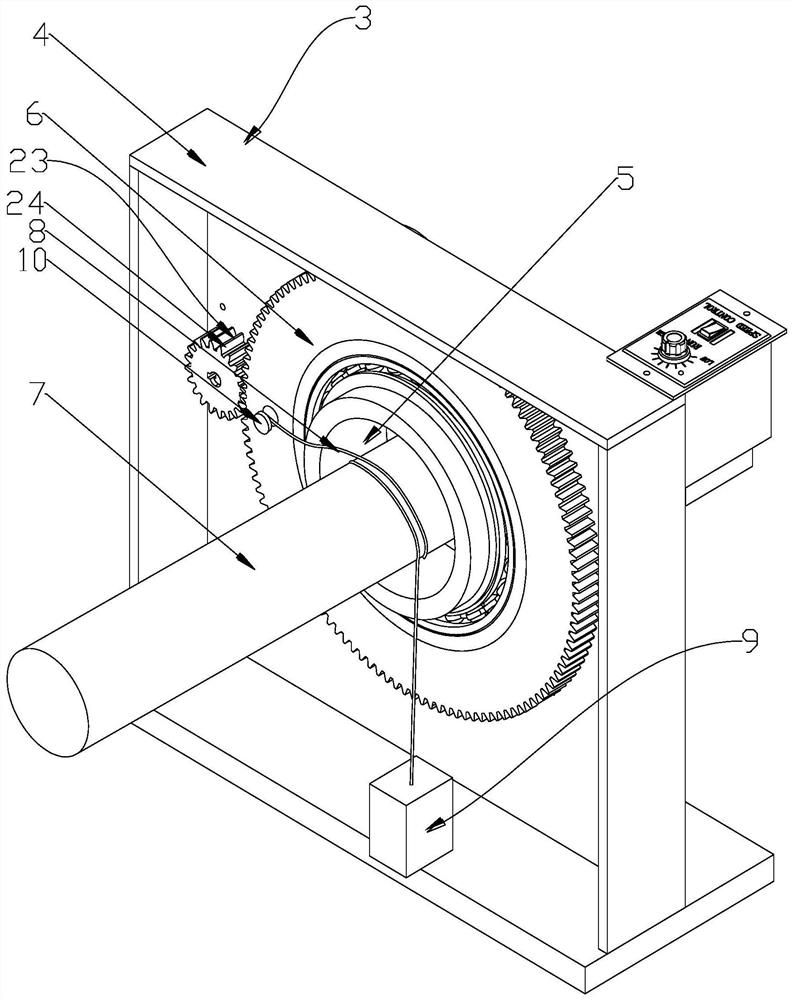

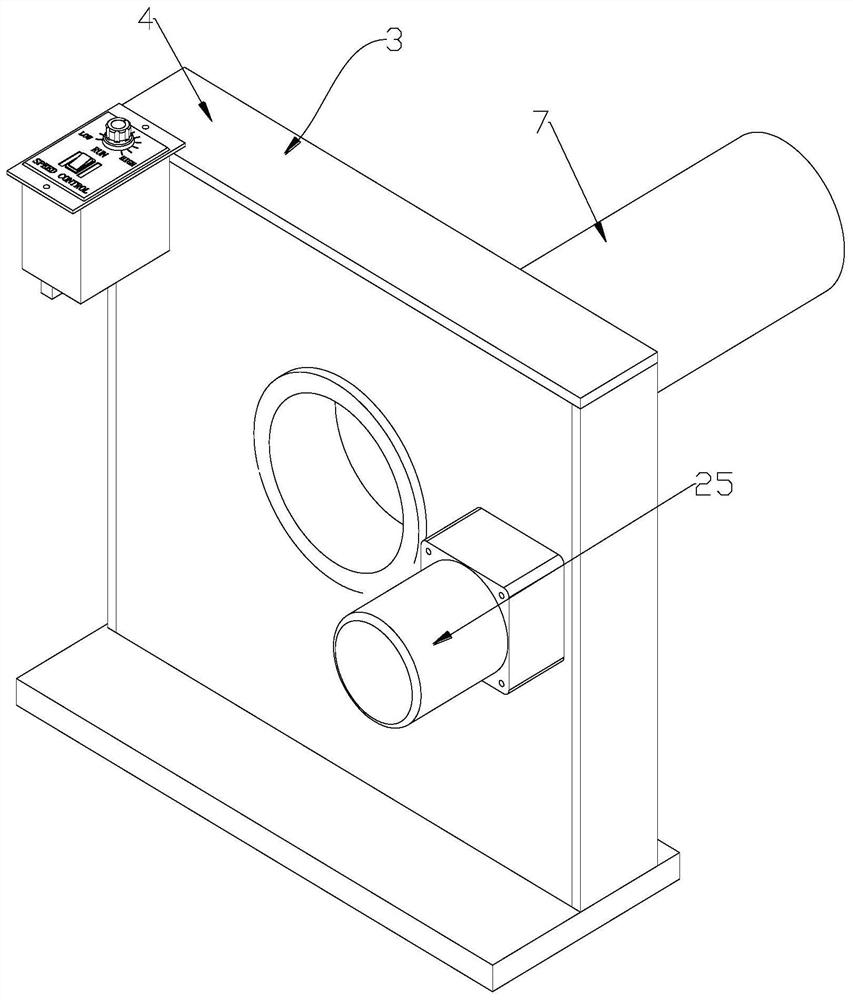

[0067] The turntable 6 is rotatably arranged on the mounting frame 4 for rotating around the steel pipe 7,

[0069] The wire pulling mechanism 9, the other end of the oil scraping wire 8 is provided with a wire pulling mechanism 9.

Embodiment 2

[0072] As shown in FIG. 2, on the basis of Embodiment 1, further, the oil scraping device 3 further includes,

[0073] The first installation seat 10 is arranged on the turntable 6, and the oil scraping line 8 is arranged on the turntable 6 through the first installation seat 10.

[0074] In this embodiment, one first mounting seat 10 is provided, and the oil scraping line 8 is arranged on the turntable 6 through the first mounting seat 10,

Embodiment 3

[0076] As shown in FIG. 4, on the basis of Embodiment 2, there are two oil scraping lines 8, which are both arranged on the first mounting seat 10, and the oil scraping lines 8 are arranged on the first mounting seat 10.

[0077] The second mounting seat 11, there are two, arranged on the turntable 6, located on both sides of the first mounting seat 10, two oil scraping lines 8

[0078] There are two limit seats 12, which are arranged on the mounting frame 4 and have a threading hole 13, and the oil scraping wire 8 is passed through the threading hole 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com