Magnetic chip removal machine

A chip removal machine and magnetic technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of incomplete chip removal, liquid corrosion equipment and environmental pollution around the equipment, and achieve the effect of thorough chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

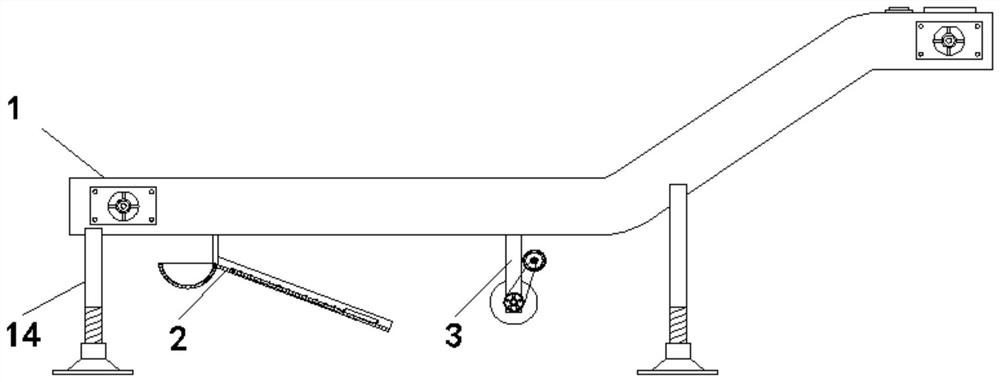

[0030] see figure 1 , a magnetic chip removal machine, including a permanent magnet chip removal machine body 1, a conveyor belt and a permanent magnet are arranged on the permanent magnet chip removal machine body 1, and a water pulse lifting part is arranged on the lower end surface of the permanent magnet chip removal machine body 1 near the end 2 and the water wheel part 3 located on the side of the water pulse lifting part 2 and distributed in the direction of the conveyor belt. The lower end surface of the permanent magnet chip removal machine body 1 is provided with four spiral telescopic legs 14. The spiral telescopic legs 14 It plays the role of supporting and adjusting the height. The water pulse lifting part 2 replaces the permanent magnet chip removal machine body 1 and is in contact with the liquid. The water wheel part 3 pushes the liquid through rotation to generate wave-like water impact, and the wave-like water impact improves the water pulse. The bit part 2 g...

Embodiment 2

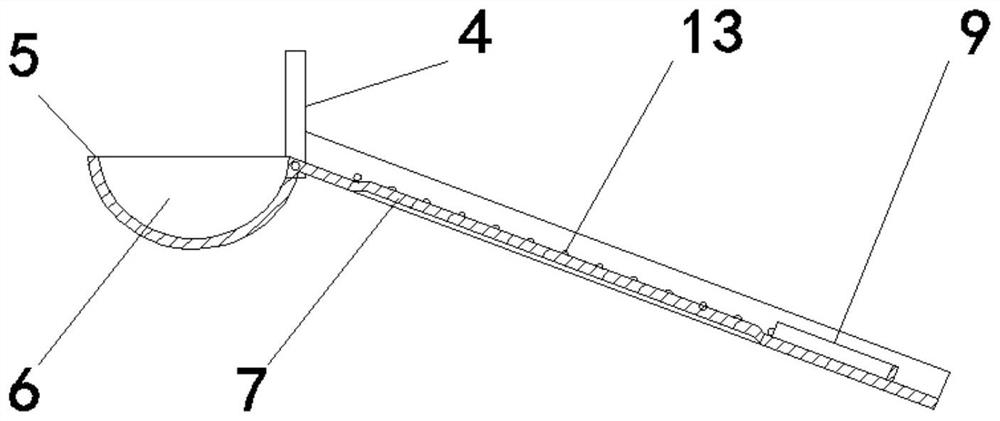

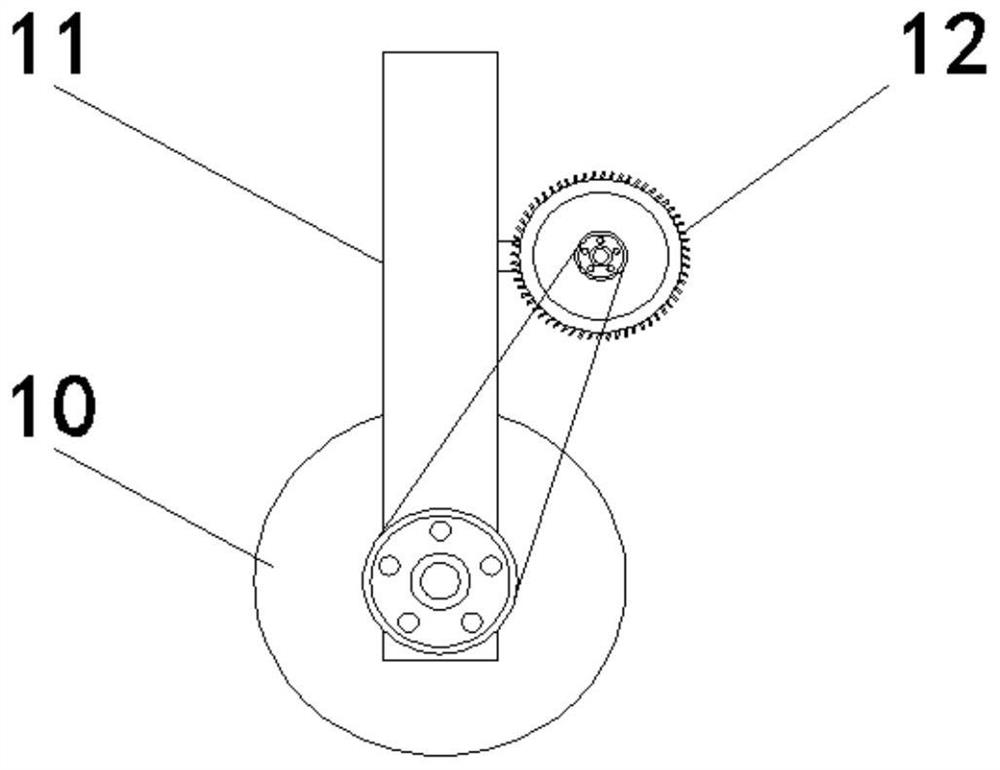

[0032] see Figure 1-3 The water pulse lifting part 2 is composed of two suspension rods 4 fixedly arranged on the top and bottom of the permanent magnet chip removal machine body 1 and symmetrically distributed, and a semicircle body 5 with a rectangular upper end surface. The upper end surface of the semicircle body 5 is provided with a semicircle The water storage tank 6, the side of the outer wall of the semicircle body 5 close to the upper end surface and the opposite side walls of the two suspension rods 4 are hinged near the bottom, the opening direction of the semicircle body 5 is upward and its side close to the two suspension rods 4 is bent There is a lifting plate 7 away from the lower end surface of the semicircular body 5 and the permanent magnet chip removal machine body 1. On the lifting plate 7, two sides close to the suspension rod 4 are bent upwards to have a right-angled water filter coaming 8. The lifting plate The upper end surface of 7 is welded with a fi...

Embodiment 3

[0034] see figure 2 , Figure 4 and Figure 5 , the middle part of the upper end surface of the lifting plate 7 is in the shape of an inverted V-shaped protrusion relatively close to the two sides of the two suspension rods 4, and the inner side walls of the two right-angled water filter enclosures 8 are provided with a uniform surface close to the upper end surface of the lifting plate 7. Distributed water holes 13, the upper end surface of the lifting plate 7 is in the shape of an isosceles trapezoid and the small end is close to the semicircular body 5. After the liquid mixed with iron filings enters the lifting plate 7, the liquid is in a V-shaped convex shape and passes through the water. Under the action of hole 13, rapid drainage and filtration are realized.

[0035] Working principle: When in use, place the four spiral telescopic outriggers 14 at the front end of the permanent magnet chip removal machine body 1 around the liquid tank containing iron filings, and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com