Original thread hair-sticking winding device based on textile processing

A technology of winding device and sticking wool, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, can solve the problems of inability to adapt to the original line, low practicability, and inflexible use, and achieves improved practicality. performance and flexibility, ease of use, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

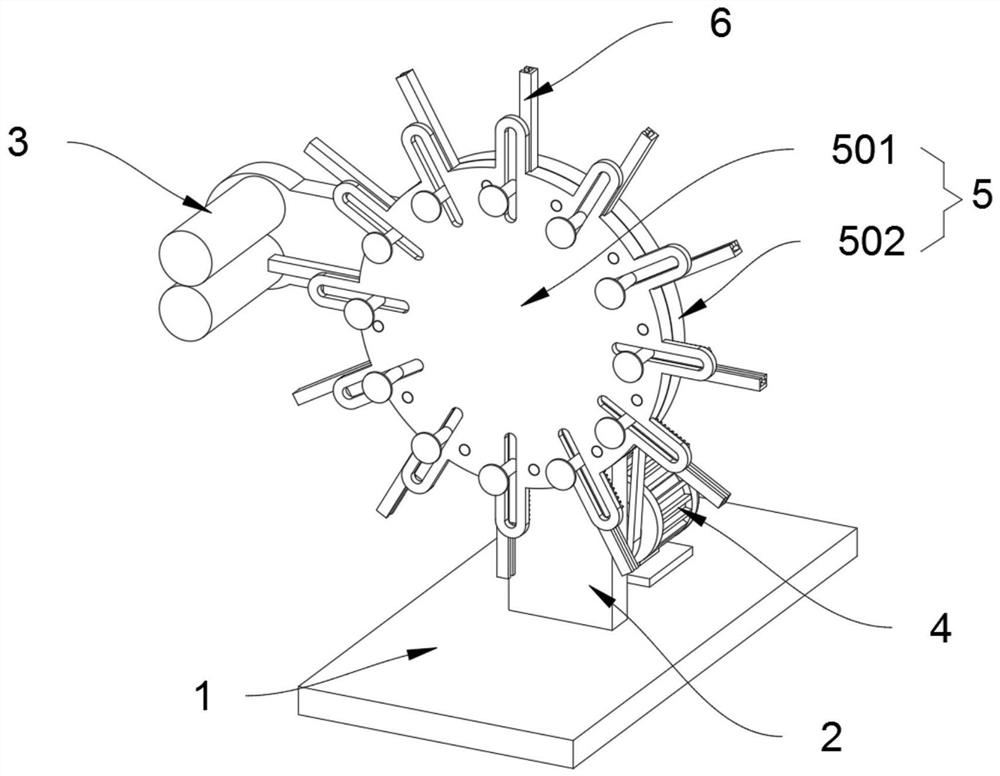

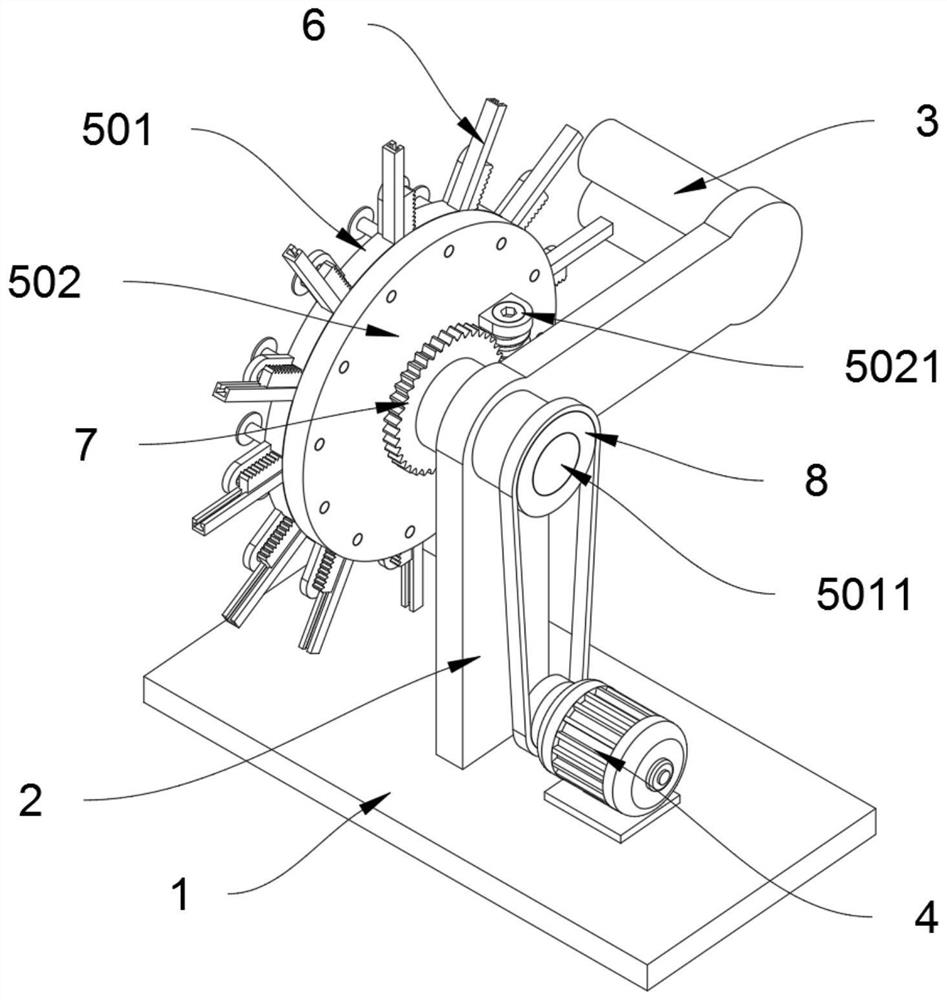

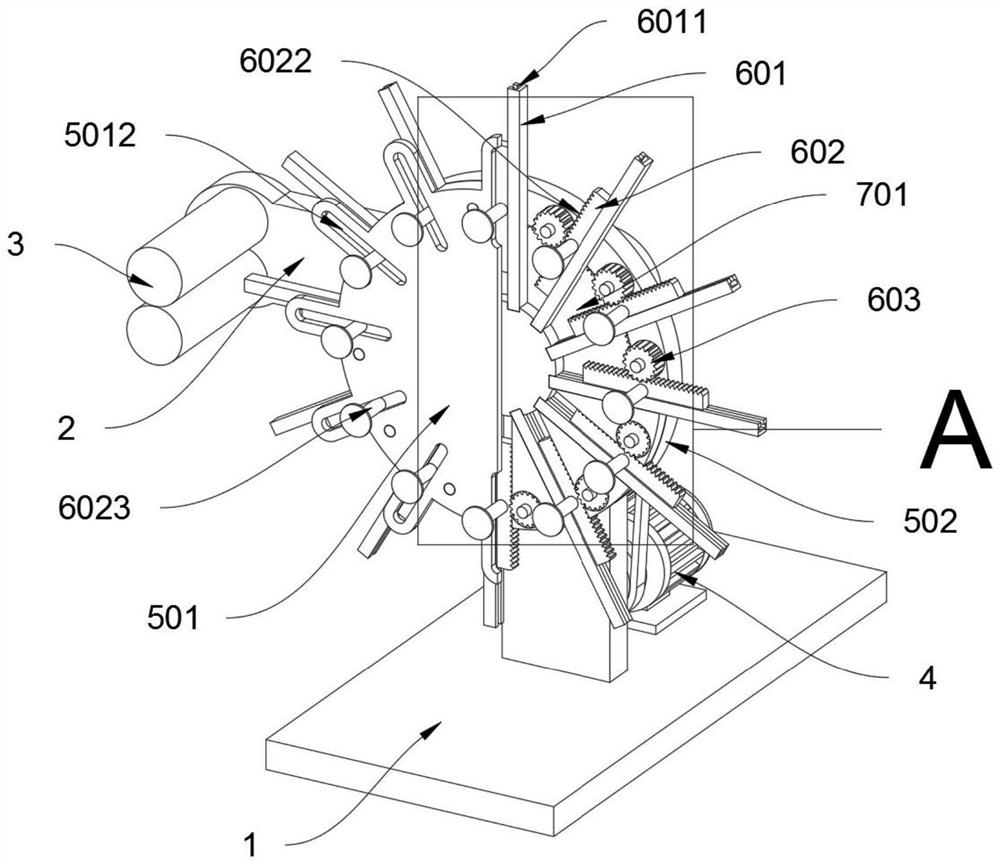

[0036] as attached figure 1 to attach Figure 9 Shown:

[0037]The present invention provides a raw thread sticking wool winding device based on textile processing, which includes a fixed base 1, a wool sticking roller 3, a driving motor 4, a rotating shell mechanism 5, an adjusting mechanism 6, a compound gear 7 and a transmission sprocket 8; The middle part of the top surface of the fixed base 1 is fixedly connected with a support plate 2; the sticky roller 3 is connected to one end of the horizontal plate of the support plate 2 in rotation; the drive motor 4 is screwed and fixed on one side of the top surface of the fixed base 1, and the drive motor 4. It is electrically connected with an external power supply and a control switch. Its specific structure and working principle are existing mature technologies, and will not be repeated here; the rotating shell mechanism 5 is composed of a front rotating shell 501 and a rear rotating shell 502; the front rotating shell 501 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com