Hoisting calipers and method for hoisting bars by using same

A lifting caliper and elevator technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of increased procurement costs, inconvenient and broken ropes and steel cables, and achieves the reduction of personal hazards, simple and compact structure, and guaranteed The effect of lifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

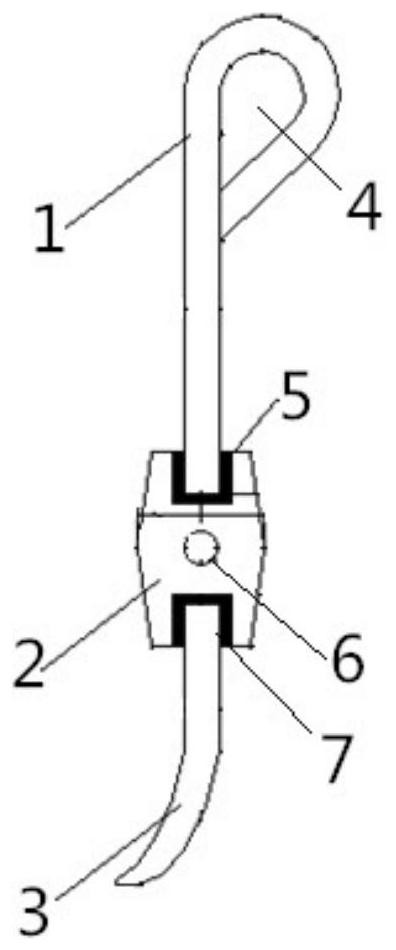

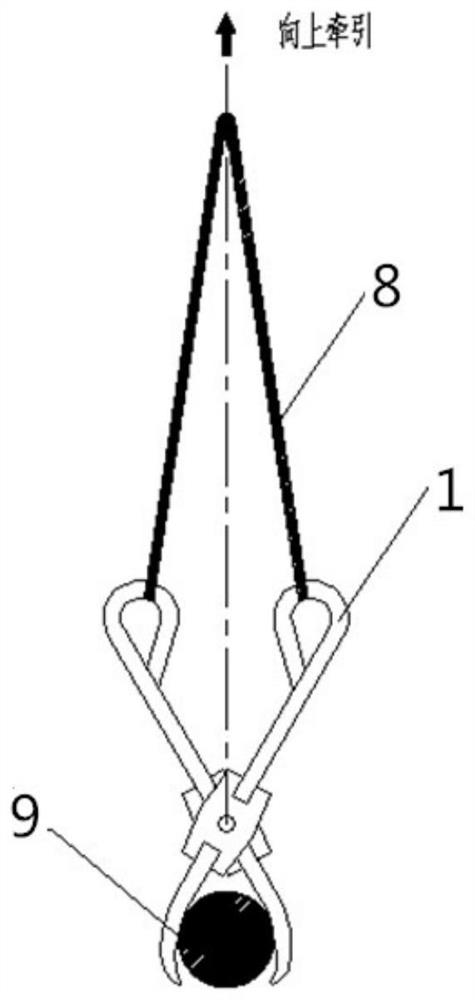

[0022] Such as figure 1 As shown, a lifting caliper includes two rotating and fixed lifting caliper units. The lifting caliper unit includes a caliper handle 1 , which is inserted into a fixed sleeve 2 , and a lifting ring 4 is arranged on the top of the caliper handle 1 ; claws 3 are arranged on the bottom of the caliper handle 1 . After mating, the area for lifting the bar 9 is formed between the jaws 3 of the two lifting caliper units.

[0023] Fixing holes 6 are provided on the fixing sleeve 2 , and the two lifting caliper units are fixed through the respective fixing holes 6 .

[0024] The caliper handle 1 is inserted into the upper groove body 5 of the fixed sleeve 2 ; the claw 3 is inserted into the lower groove body 7 of the fixed sleeve 2 .

[0025] Such as figure 2 As shown, a method for hoisting bars by lifting calipers comprises the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com