Surface water pollution treatment equipment

A water pollution and equipment technology, applied in the field of water pollution treatment, can solve the problems of slow sludge dewatering, increase the bearing capacity of the external blade of the screw, slow down the rotation speed of the screw, etc. The effect of rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] as attached figure 1 to attach Figure 5 Shown:

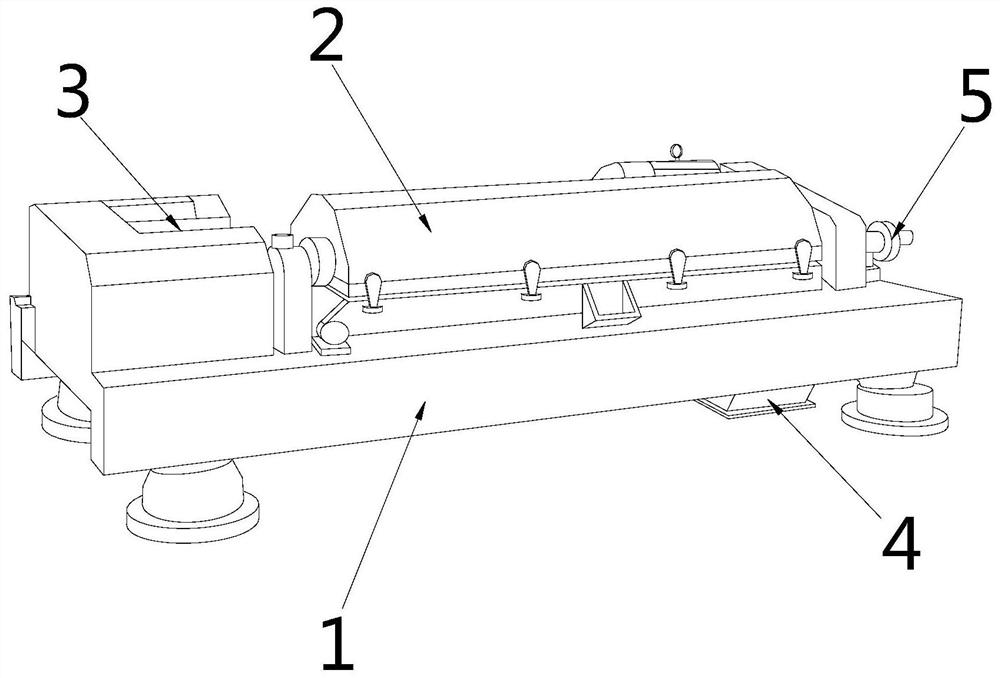

[0026] The invention provides a surface water pollution treatment equipment, the structure of which includes a base 1, a drum 2, a water inlet 3, a sludge outlet 4, and a water outlet 5, the drum 2 is set on the top of the base 1, and the water inlet 3 is located on the top of the drum 2 on the left side, the sludge outlet 4 is located on the right side of the bottom of the base 1, and the water outlet 5 is connected to the right end of the drum 2.

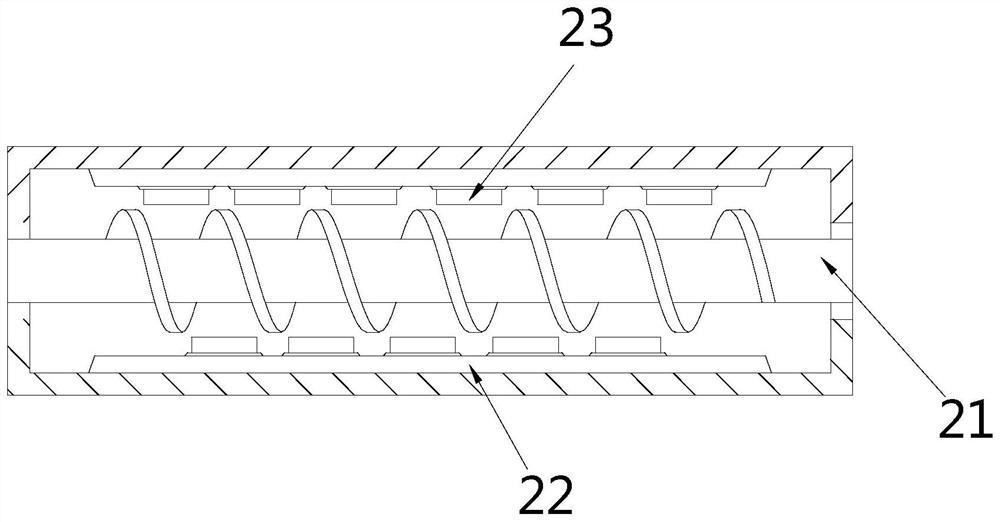

[0027] The drum 2 includes a screw rod 21, a support seat 22, and a block 23, the screw rod 21 is arranged in the middle of the drum 2, the support seat 22 is fixed on the inner wall of the drum 2, and the block 23 is installed on the support seat 22 surface.

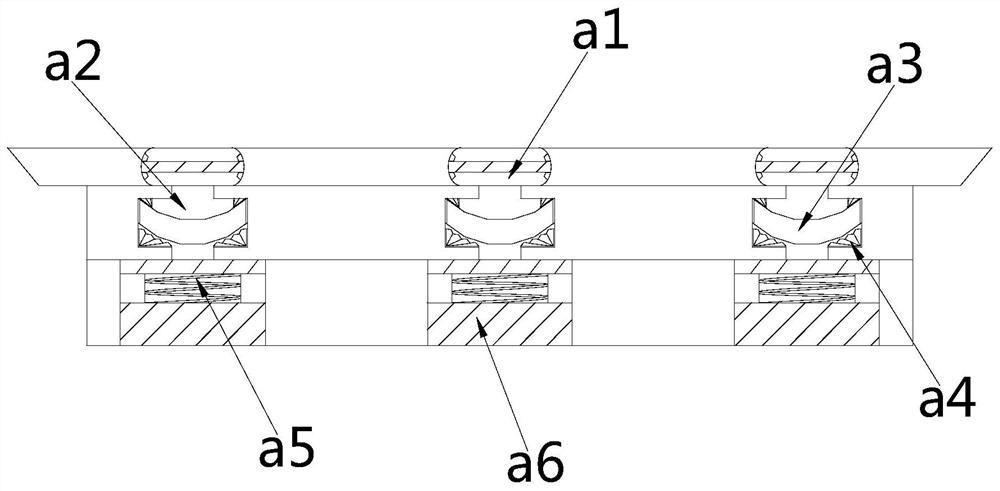

[0028] Wherein, the block 23 includes an opening a1, a water tank a2, an impact plate a3, a bottom block a4, a spring a5, and a clearing block a6, the opening a1 runs through the top of the block 23, the water tank...

Embodiment 2

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035] Wherein, the impact plate a3 includes a top groove r1, a water inlet groove r2, a push rod r3, an extrusion block r4, a water storage chamber r5, and a bottom plate r6. The top groove r1 runs through the top of the impact plate a3, and the water inlet groove r2 respectively Located on the inner walls of both sides of the impact plate a3, the push rod r3 is arranged on both sides of the inner wall of the impact plate a3, the extrusion block r4 is movably matched with the push rod r3, the water accumulation chamber r5 is located inside the impact plate a3, and the bottom plate r6 is fixed on the bottom surface of the impact plate a3, and the surface of the extrusion block r4 close to the middle of the impact plate a3 is an irregular surface, which is beneficial to increase the contact area with the sewage, accelerate the extrusion of the sewage, and increase the impact force of the sewage.

[0036] Wherein, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com