Control method of steam cooking equipment and steam cooking equipment

A technology for cooking equipment and control methods, which is applied to steam cooking utensils, timing control ignition mechanisms, cooking utensils, etc., and can solve problems such as insufficient steam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

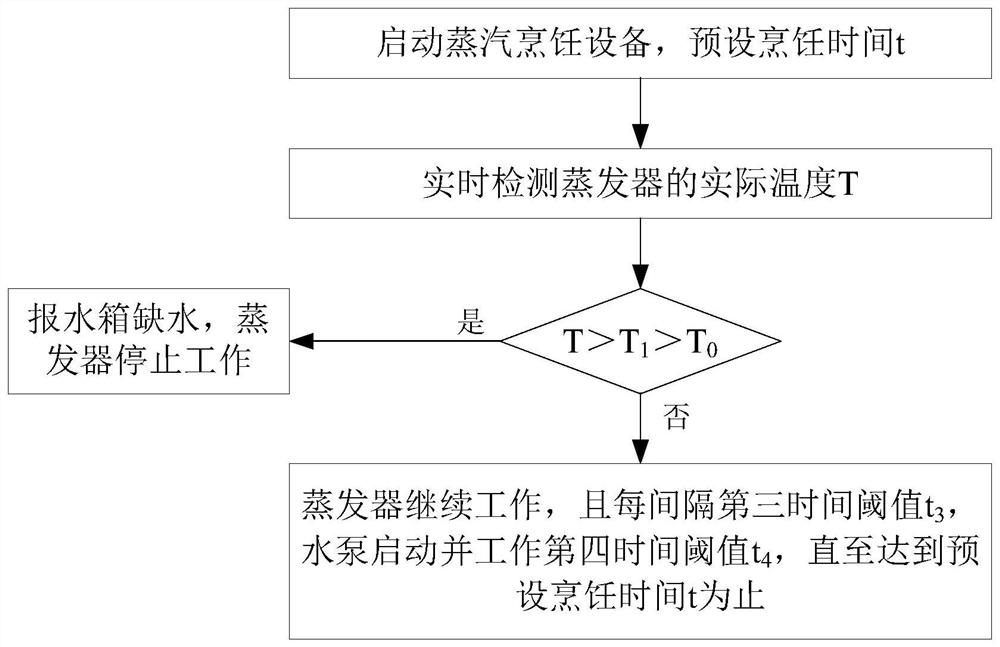

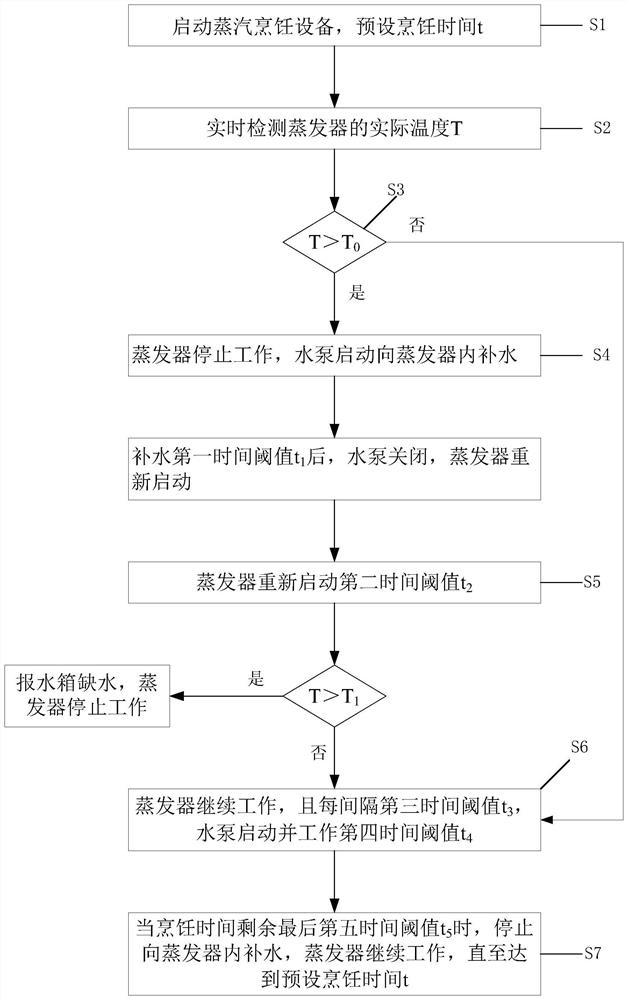

[0045] This embodiment provides a method for controlling steam cooking equipment, such as figure 1 As shown, the method includes the following steps:

[0046] Start the steam cooking equipment and preset the cooking time t;

[0047] For example, according to different foods, select a cooking mode and preset different cooking times t;

[0048] Real-time detection of the actual temperature T of the evaporator;

[0049] Determine whether the actual temperature T satisfies: T>T 1 >T 0 ; T 1 is the water shortage temperature threshold of the water tank; T 0 is the dry burning temperature threshold of the evaporator;

[0050] If so, report that the water tank is short of water, and the evaporator stops working;

[0051] If not, the evaporator continues to work, and every third time threshold t 3 , the water pump starts and works for the fourth time threshold t4 , until the preset cooking time t is reached.

[0052] If the actual temperature T satisfies: T1 , it means that t...

Embodiment 2

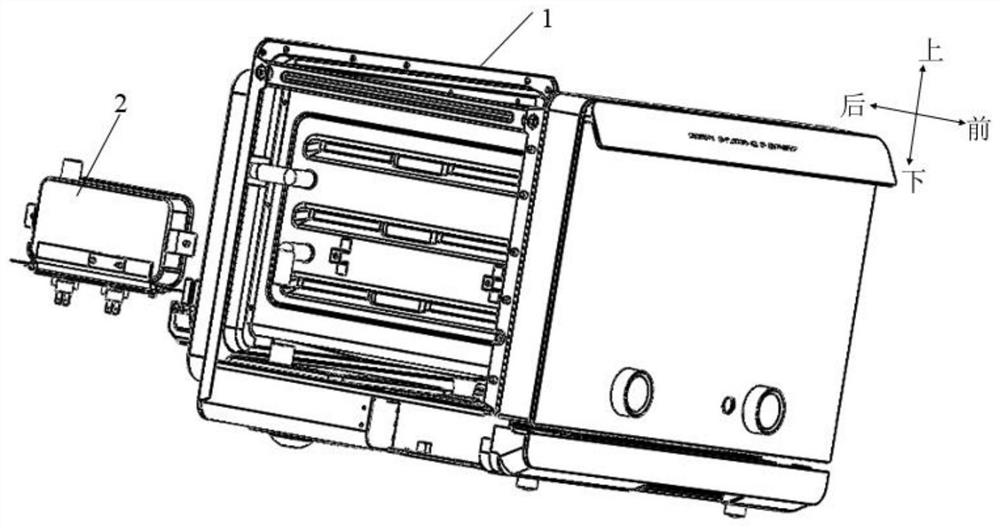

[0068] This embodiment provides a steam cooking device, such as image 3 As shown, the cooking device body 1, the evaporator 2 and the temperature detection unit; the evaporator 2 is suspended and installed on the side plate of the cooking device body 1 to increase the height of the water in the evaporator 2; the temperature detection unit is installed on the evaporator away from the bottom of the water 2 on the side wall.

[0069] The current evaporator is usually installed on the top plate of the cooking equipment body, and the evaporator is usually designed in a flat shape, and the evaporator is lying on the top plate. At this time, the height of the water in the evaporator is relatively low. scale, it will lead to the inability to detect the temperature of the evaporator more accurately, so in this embodiment, the evaporator is suspended and installed on the side plate of the cooking device body 1, without changing the current structure of the evaporator, The height of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap