Silicon carbide micro-powder crushing, grinding and screening machine

A silicon carbide micropowder and screening machine technology, applied in grain processing and other directions, can solve the problems of poor pulverization effect, affecting work efficiency, large particles, etc., and achieve the effect of reducing power, improving work efficiency, and grinding finely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

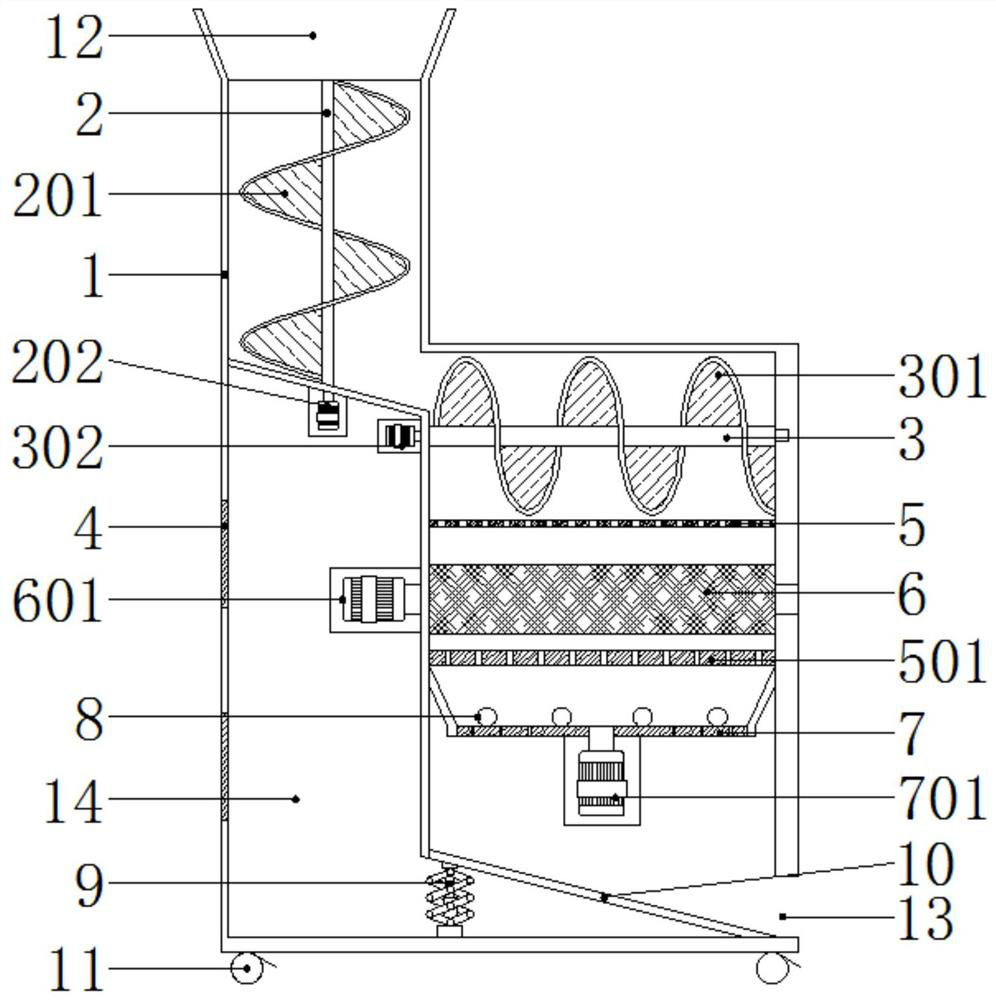

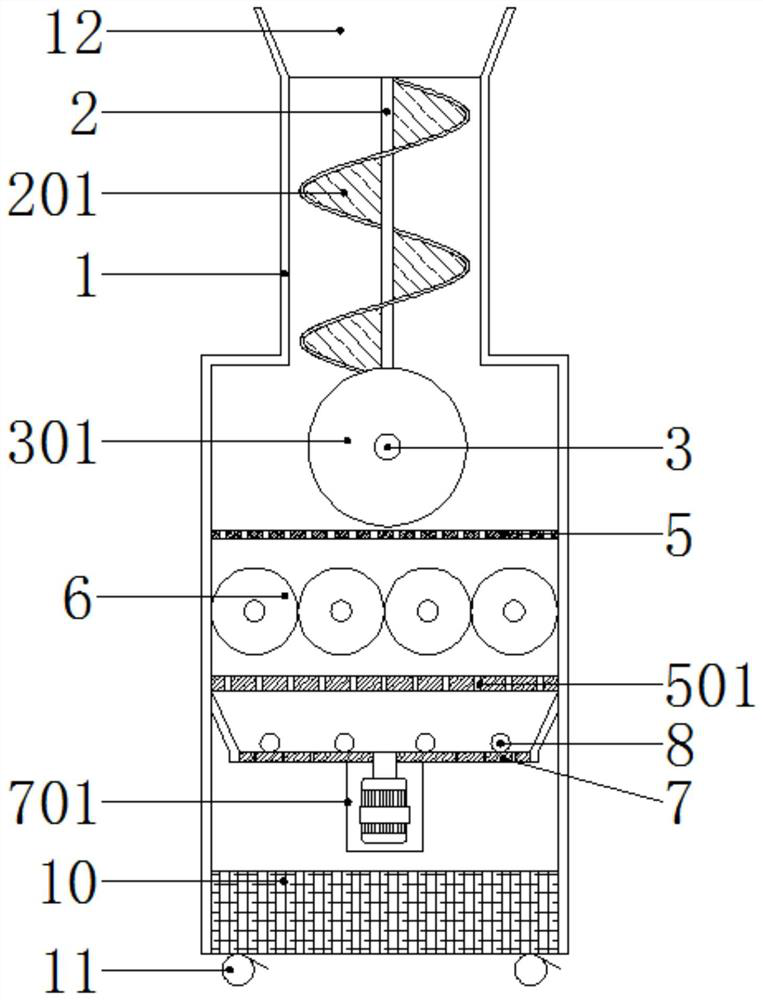

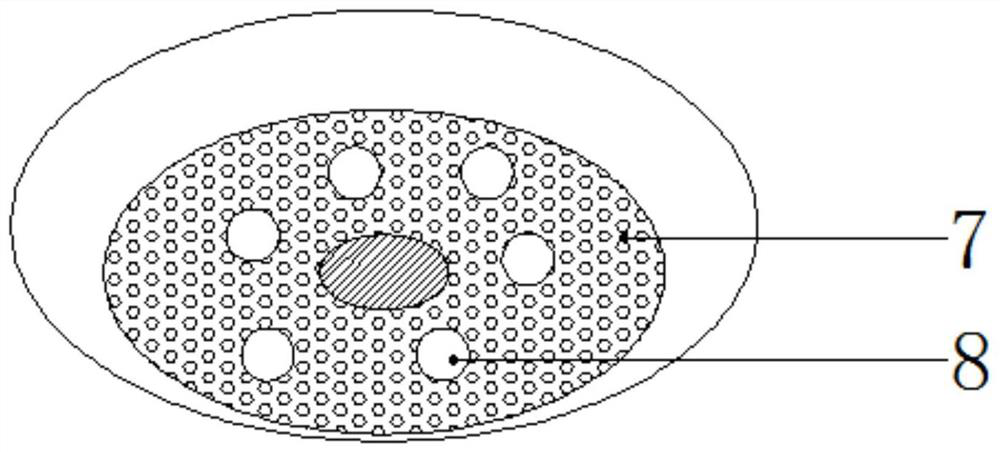

[0019] Example: such as Figure 1-3 As shown, a silicon carbide micropowder crushing, grinding and screening machine of the present invention includes a body 1, the top of the body 1 is fixedly provided with a feed port 12, and the bottom end of the feed port 12 is fixedly equipped with a first rotating rod 2 , the first rotating rod 2 is fixedly provided with a first crushing knife 201, the bottom end of the first rotating rod 2 is provided with an inner box 14, and one side of the inner box 14 is fixedly installed with a second rotating rod 3 , the second rotating rod 3 is fixedly provided with a second crushing knife 301, the bottom end of the second rotating rod 3 is fixedly equipped with a first screen 5, and the bottom end of the first screen 5 is fixedly provided with Grinding cylinder 6, the bottom end of described grinding cylinder 6 is fixedly provided with second screening net 501, and the bottom end of described second screening net 501 is fixedly installed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com