Handheld folding grinding machine for machining detection of casting and forging

A hand-held, casting and forging technology, which is applied in the direction of grinding racks, portable grinding machines, metal processing equipment, etc., can solve the problems of limited application range, single grinding method, inconvenient use, etc., to achieve a wide application range and reduce operation Improved stability and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

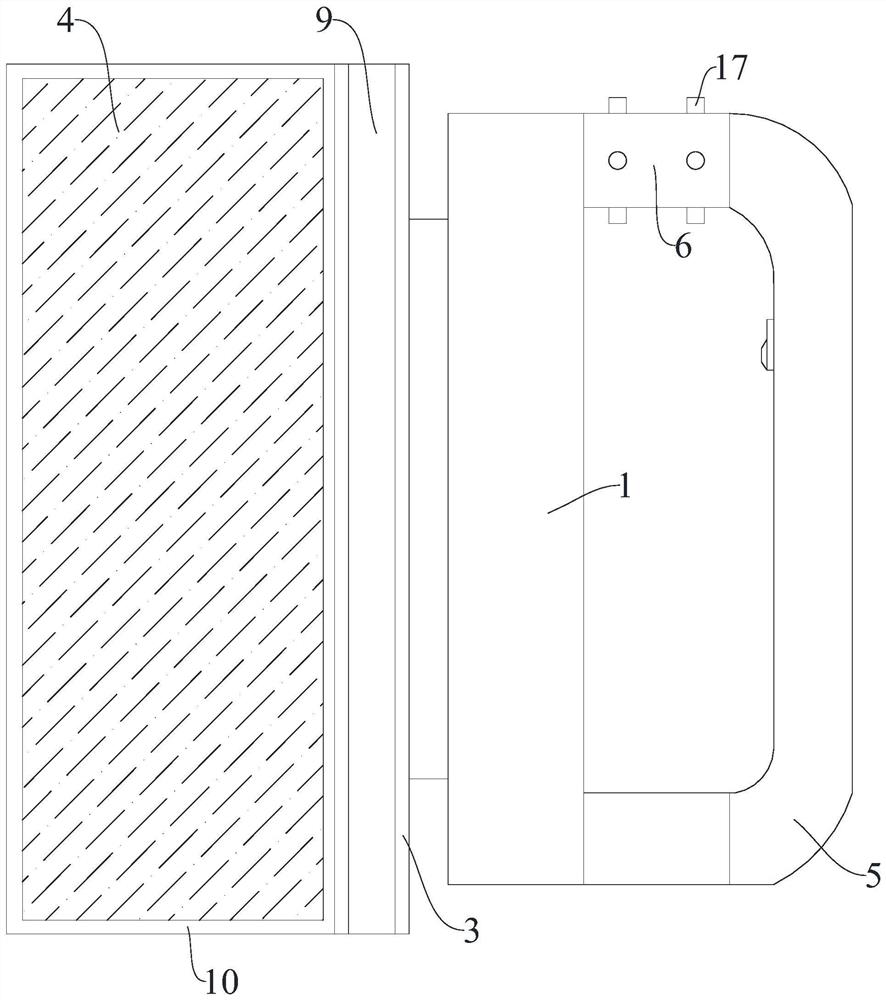

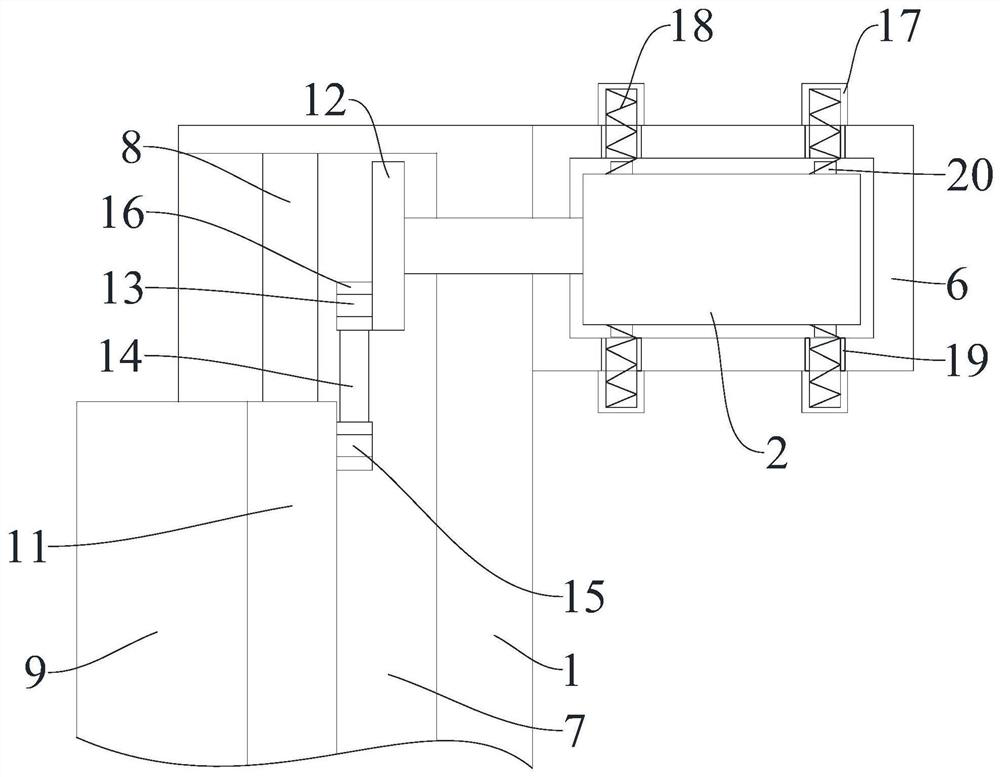

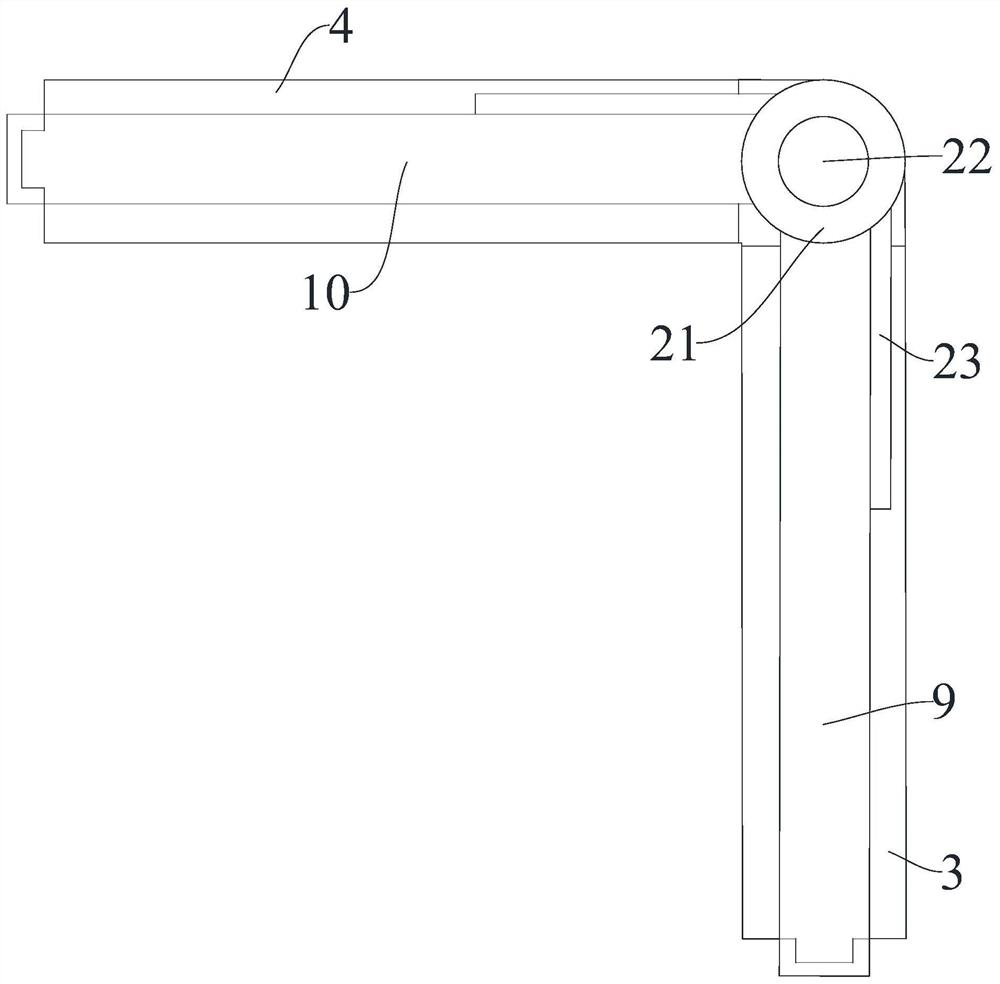

[0029] Embodiment: People toggle the manual switch, the drive motor 2 starts, drives the bottom transmission disc 12 to rotate, and the bottom transmission disc 12 drives the lateral eccentric shaft 13 to rotate. The lateral connecting rod 14 on the lateral eccentric shaft 13 drives the external guide tube 11 to reciprocate in translation along the internal guide tube 8, thereby synchronously driving the internal and external mounting frames to reciprocate.

[0030] A hand-held folding grinder for processing and testing casting and forging parts of the present invention is composed of an external installation box 1, a drive motor 2, a first grinding block 3 and a second grinding block 4, and on the side wall of the external installation box 1 there is a The lateral mounting groove 7 of the inner and outer mounting frames is built in, and the grinding block is installed through the inner and outer mounting frames, and the inner and outer mounting frames are folded and installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com