Cooling water recycling device

A technology for cooling water and water pumps, applied in water/sewage treatment, water/sewage treatment equipment, multi-stage water/sewage treatment, etc., can solve problems affecting the surrounding environment, resource loss, and inconvenient direct use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

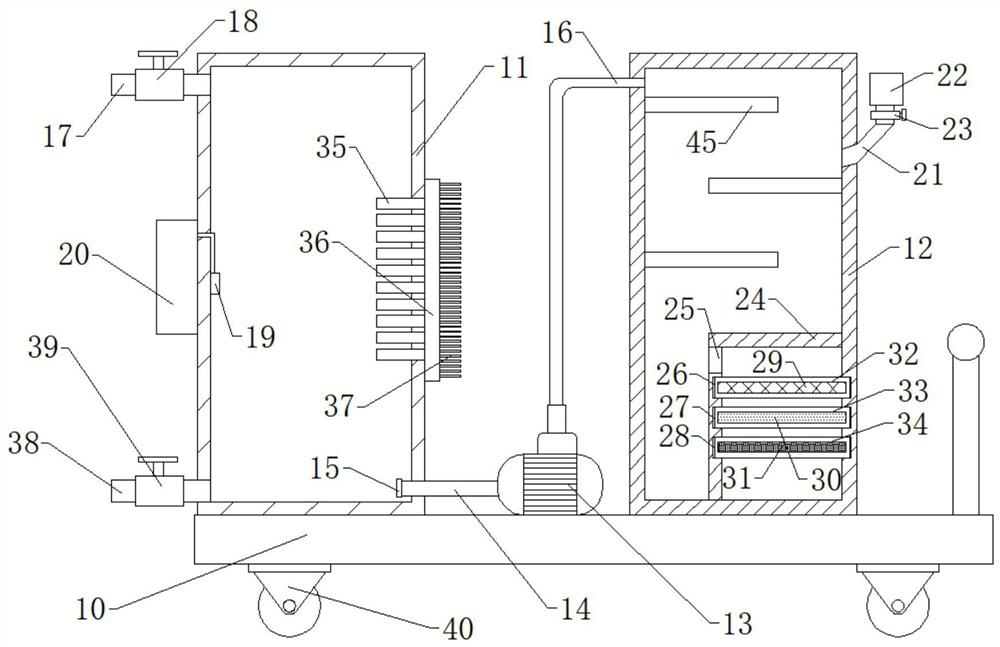

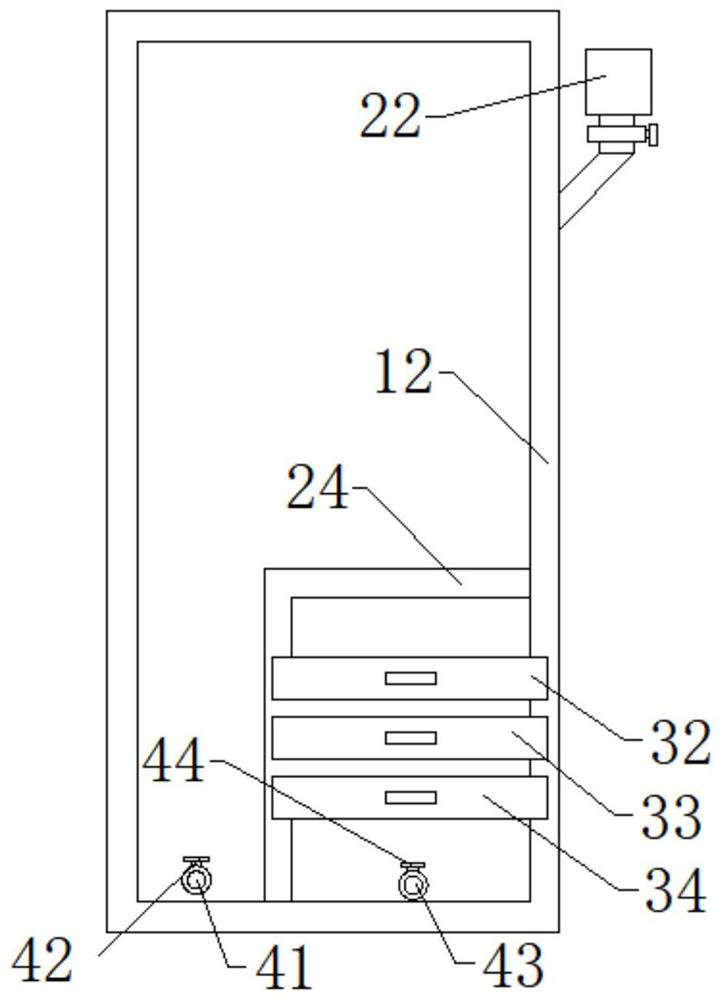

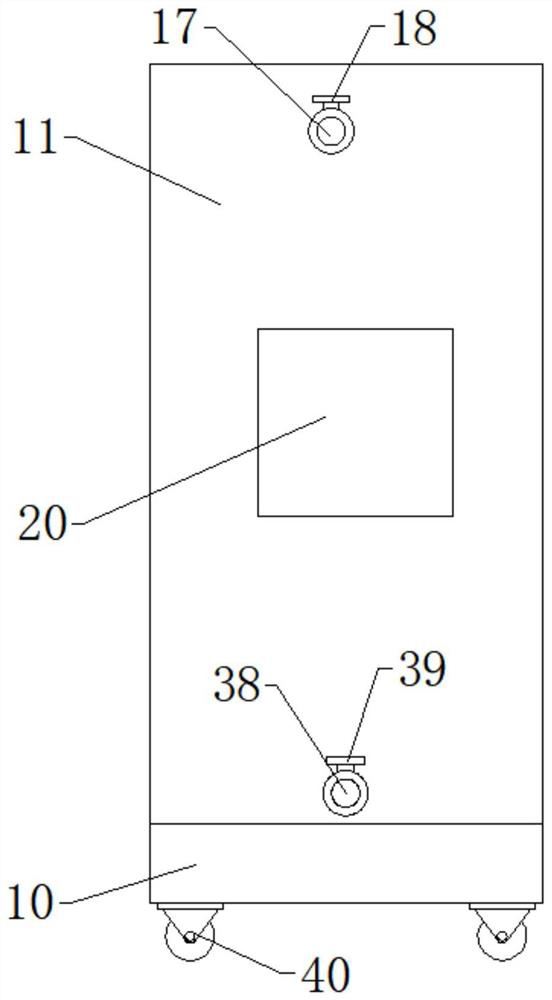

[0020] see Figure 1-4 , the present invention provides a technical solution: a cooling water recovery and reuse device, including a bottom plate 10, the upper surface of the bottom plate 10 is fixedly connected with a first box 11 and a second box 12 respectively, and the upper surface of the bottom plate 10 is screwed There is a water pump 13, the water inlet of the water pump 13 is connected with a first pipe body 14, the end of the first pipe body 14 away from the first box body 11 runs through the inner side wall of the first box body 11 and is threadedly connected with a filter screen cover 15, the water pump 13 The water outlet of the second pipe body 16 is connected with the second pipe body 16, and the end of the second pipe body 16 away from the water pump 13 runs through the inner side wall of the second box body 12, and the side of the first box body 11 is connected with a third pipe body 17, and the third pipe body 17 The outer side wall of body 17 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com