A kind of synthetic method of 1-phenyl-5-mercaptotetrazolium

A technology of mercaptotetrazolium and synthesis method, applied in the field of synthesis of 1-phenyl-5-mercaptotetrazolium, capable of solving the problems of complex production methods, difficult purification, low yield, etc., and achieving simple and easy post-processing , high reactivity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

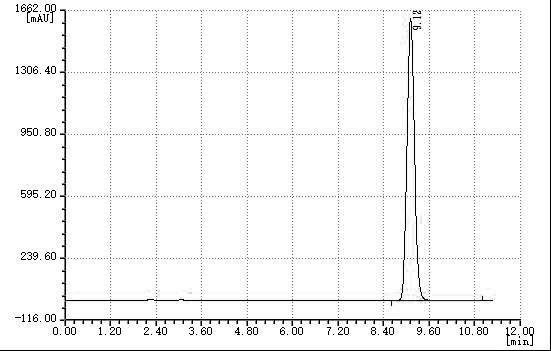

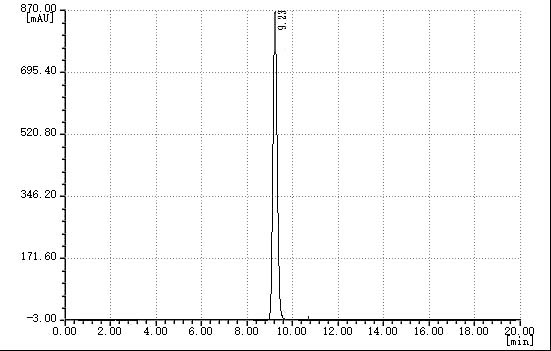

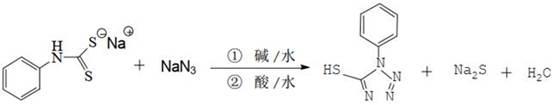

[0026] Add 290kg of sodium anilinodithiocarboxylate and 1167kg of water to the 5000L reaction kettle in turn, mix and start stirring, slowly add the catalyst, that is, 404kg of sodium hydroxide solution with a mass fraction of 30%, and add azide to the reaction system under stirring. Sodium 103.6kg, heat up to 90°C and keep it warm for 11 hours, cool down to 8°C after sampling and testing is qualified, filter with suction, heat up the filtrate to 35°C, stir for 30min, neutralize with 149kg of concentrated sulfuric acid solution until the pH of the solution is 2, stir for 30min evenly Afterwards, re-test the PH no longer changed, lower the temperature to 9°C, and suction filter to obtain the crude product of filter cake 1-phenyl-5-mercaptotetrazolium, and the obtained crude product of 1-phenyl-5-mercaptotetrazolium was fully dissolved Carry out recrystallization in the recrystallization solution that 510L mass fraction is 85% toluene / 15% water, the mass fraction of toluene is 85...

Embodiment 2

[0028] Add 290kg of sodium anilinodithiocarboxylate and 1557kg of water to the 5000L reaction kettle in turn, mix them, start stirring, slowly add the catalyst, that is, 303kg of sodium hydroxide solution with a mass fraction of 40%, and add azide to the reaction system under stirring. Sodium 108.6kg, heat up to 95°C and keep it warm for 10 hours, cool down to 10°C after sampling and testing is qualified, filter with suction, heat up the filtrate to 30°C, stir for 30min, neutralize with 149kg of concentrated sulfuric acid solution until the pH of the solution is 3, stir for 60min After mixing evenly, re-test the PH no longer changes, lower the temperature to 10°C, and filter with suction to obtain the crude product of filter cake 1-phenyl-5-mercaptotetrazolium, and the obtained 1-phenyl-5-mercaptotetrazolium The crude azole product was fully dissolved in 758L of 90% toluene / 10% water for recrystallization, separated and dried to obtain 253 kg of finished product, with a product...

Embodiment 3

[0030] Add 290kg of sodium anilinodithiocarboxylate and 1847kg of water in turn to the 5000L reactor, mix and start stirring, slowly add the catalyst dropwise, that is, 242.4kg of sodium hydroxide solution with a mass fraction of 50%, and add azide to the reaction system under stirring Sodium chloride 113.5kg, heat up to 85°C and keep it warm for 12 hours. After the sampling test is qualified, cool down to below 9°C, filter with suction, heat the filtrate to 30°C, stir for 30 minutes, and mix the solution evenly. Retest the pH without changing. Use 149kg concentrated Sulfuric acid solution was neutralized until the pH of the solution was 2, stirred for 30-60min, then cooled to 8°C, suction filtered, and the crude product of filter cake 1-phenyl-5-mercaptotetrazolium was obtained by suction filtration, and the obtained 1-phenyl-5- - The crude product of mercaptotetrazolium fully dissolved in 510L with a mass fraction of 95% toluene / 5% water recrystallized, separated and dried to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com