An intelligent detection and cleaning robot for storage tanks

A technology for cleaning robots and storage tanks, applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems affecting product quality, affecting detection and cleaning effects, affecting storage tank efficiency, etc. Increase safety and stability, prevent key pollution and corrosion, and prevent the body from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

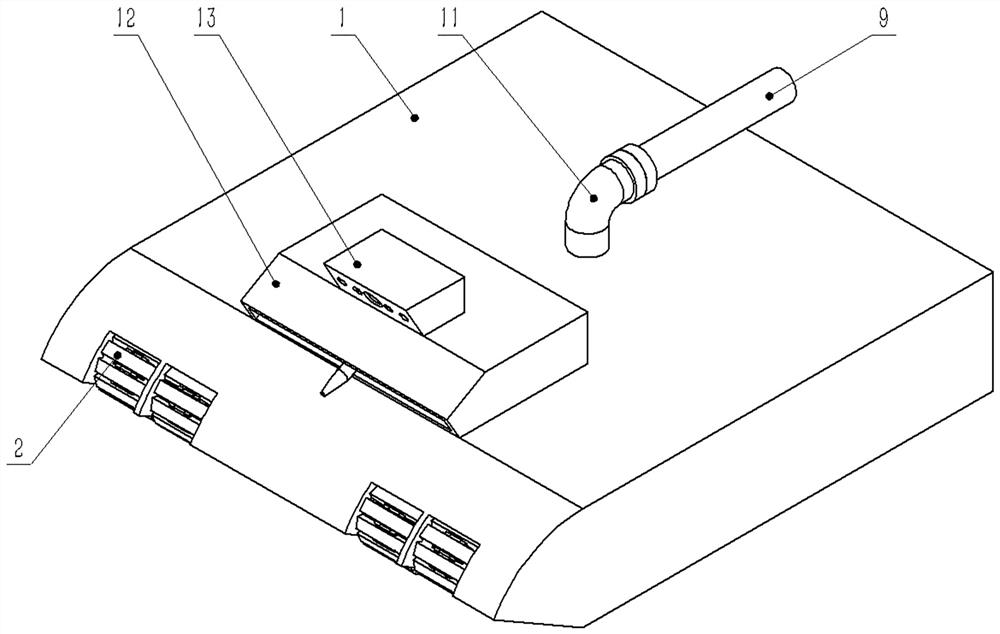

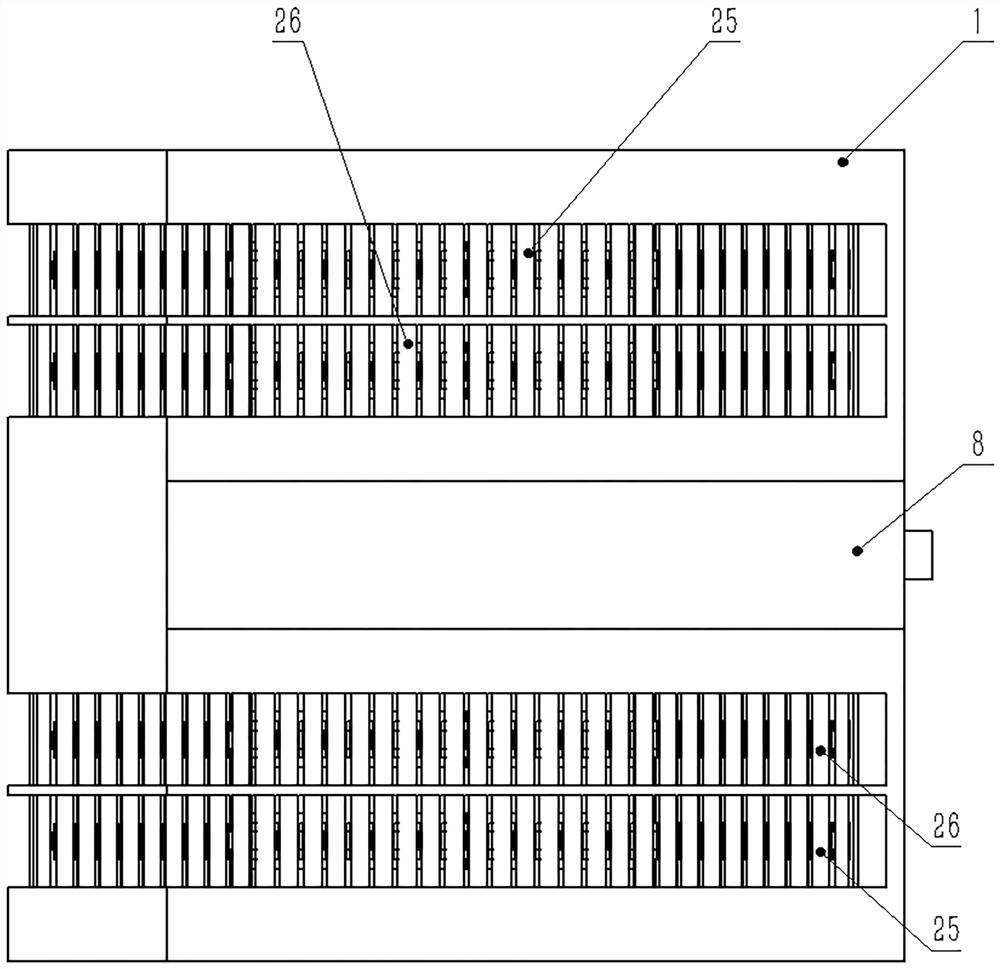

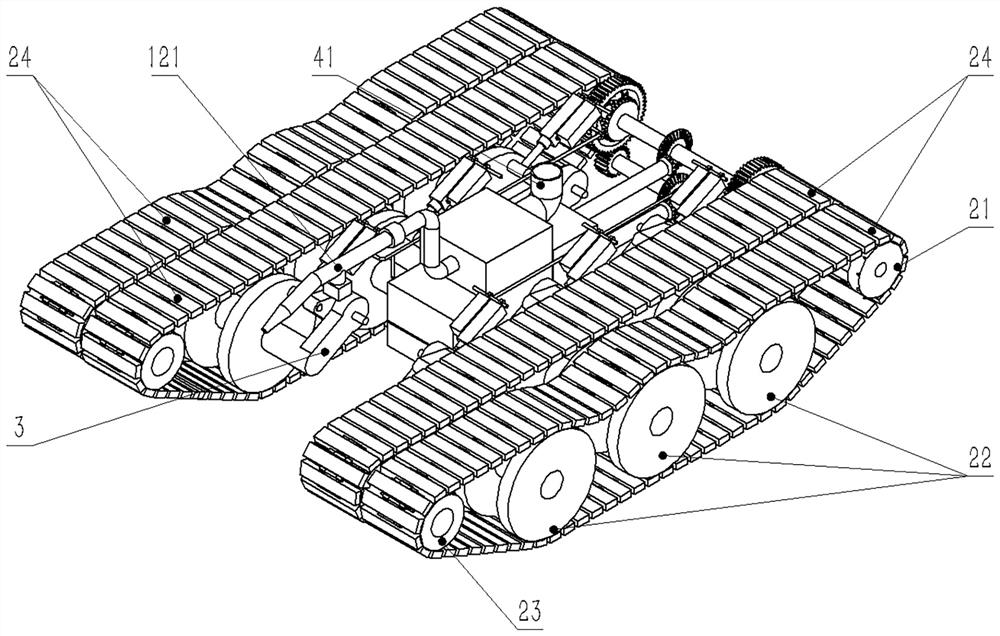

[0048] like figure 1 As shown, this embodiment is an intelligent storage tank detection and cleaning robot, including a flat body 1 shell, the upper part of the front end of the body 1 is set as a circular arc surface, and the lower part is set as an inclined surface; the circular arc surface is used to cooperate with the setting The high-pressure spray head 121 arranged in the flushing box 12 at the top front end of the body 1 prevents the front end from obstructing the path of the high-pressure spray head 121 for spraying water and ensures the strength of the washing. Enhance the walking obstacle ability of this embodiment to make it have a stronger passing ability when facing a protruding obstacle in front; such as image 3 and Figure 4 As shown, the high-pressure spray head 121 is arranged on the spray head control shaft 122, the spray head control shaft 122 is arranged on the spray head control motor 123, and the spray head control motor is arranged at the bottom of the...

Embodiment 2

[0058] like Figure 10 As shown, in this embodiment, an automatic brush 6 is installed at the rear of the body 1. The automatic brush 6 includes two symmetrical brush frames 61. The brush frame 61 is an L-shaped hollow structure, and its short side ends It is connected by a brush shaft 62, and the brush shaft 62 is covered with bristles.

[0059] like Figure 11 As shown, a transmission system is arranged inside the brush frame 61, including a driving wheel connecting extension shaft 64 directly connected with the driving wheel connecting shaft 26; the driving wheel connecting extension shaft 64 can rotate synchronously with the driving wheel connecting shaft 56, that is, it can It rotates synchronously with the rotation of the driving wheel 21; the end of the driving wheel connecting extension shaft 64 is connected with the brush drive shaft 63 through gear fitting, and the two are arranged perpendicular to each other; the brush drive shaft 63 is along the length of the brus...

Embodiment 3

[0065] like Figure 13 , 14 As shown in the figure, the technical solution used in this embodiment is basically the same as the above-mentioned embodiment, and the main difference is that: in this embodiment, the body 1 is extended, so that the automatic brush 6 is covered by the body 1, and is stored in the body 1. Inside; a waste liquid recovery tank 14 is fixedly arranged at the rear of the body 1 , and a hot air drying mechanism 15 is fixed behind the waste liquid recovery tank 14 .

[0066] like Figure 14 , 15 As shown, the waste liquid recovery tank 14 is fixedly connected to the top of the tail of the body 1 through the ball rod connection mechanism 145, and a suspension spring 147 is provided between the top of the tail of the body 1 and the protruding plate part at the top of the waste liquid recovery tank 14; The cooperative connection between the connecting mechanism 145 and the several suspension springs 147 enables the waste liquid recovery tank 14 to rotate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com