Moisture-resistant composition and preparation method thereof

A composition and water vapor technology, applied in the direction of non-polymer organic compound adhesives, adhesive types, adhesive additives, etc., can solve the problems of poor water vapor resistance, achieve enhanced waterproof performance, improve compactness, and improve effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The second aspect of the embodiment of the present application provides a method for preparing a water vapor resistant composition, comprising the following steps:

[0064] S01. Provide each weight component according to the water vapor resistant composition;

[0065] S02. Provide an environment without ultraviolet light, and perform the first mixing treatment on the reactive diluent, photoinitiator, photoinitiation auxiliary agent and other auxiliary agents to obtain the first mixture;

[0066] S03. Grinding the epoxy resin and the anti-moisture component to obtain a second mixture;

[0067] S04. The first mixture and the second mixture are subjected to a second mixing treatment to obtain a crude product of a moisture-resistant composition;

[0068] S05. Post-treating the crude water vapor resistant composition to obtain a water vapor resistant composition.

[0069] The second aspect of the present application provides a method for preparing a water vapor-resistant c...

Embodiment 1

[0078] water vapor resistant composition

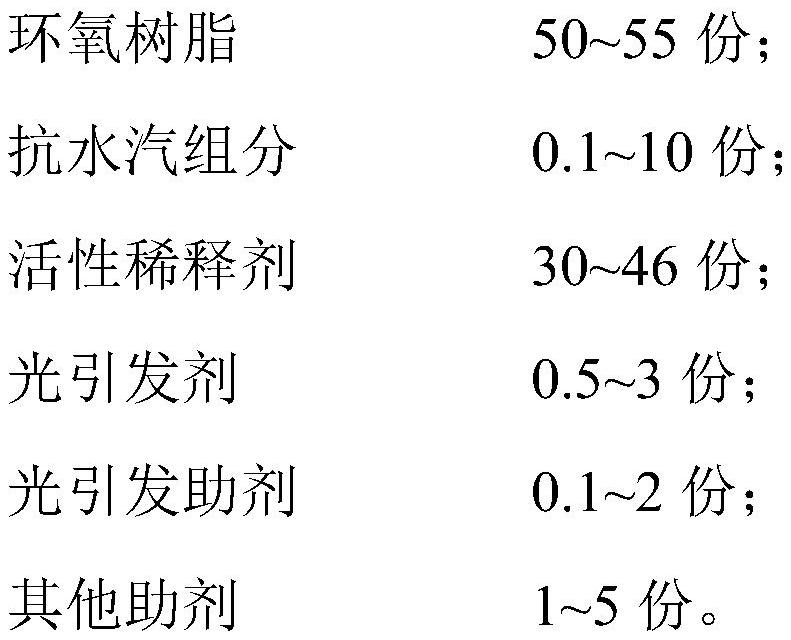

[0079] The water vapor resistant composition comprises the following components in the following parts by weight:

[0080]

[0081] Wherein, epoxy resin is selected from the EP1KOTE 828EL that Hexion Specialty Chemicals provides;

[0082] The anti-moisture component is selected from GENIOSIL STP E30 provided by Wacker Chemicals;

[0083] The reactive diluent is selected from HELOXY Modifier 65 provided by Heloxy Chemicals;

[0084] The photoinitiator is selected from SilForce UV9380C provided by Momentive Performance Materials Inc.;

[0085] Photoinitiation auxiliary agent is selected from the QC (camphorquinone) of Aladdin;

[0086] Other additives are selected from KH560 (γ-(2,3-epoxypropoxy)propyltrimethoxysilane) provided by Aladdin.

[0087] Preparation method of water vapor resistant composition

[0088] According to the water vapor resistant composition of embodiment 1, each weight component is provided;

[0089] Pr...

Embodiment 2

[0094] water vapor resistant composition

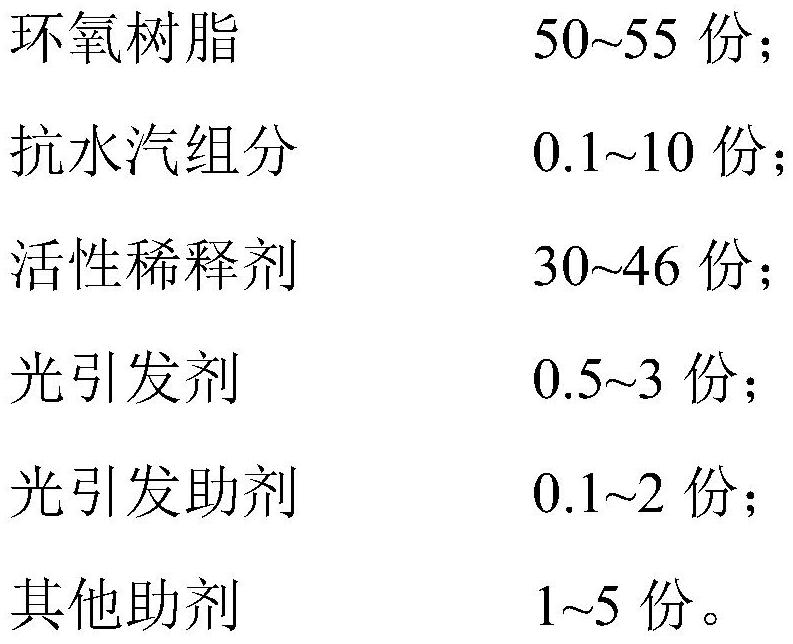

[0095] The water vapor resistant composition comprises the following components in the following parts by weight:

[0096]

[0097] Wherein, epoxy resin is selected from the mixture of EP1KOTE 828EL provided by 40 parts of Hexion Specialty Chemicals and EP-4080E provided by 10 parts of ADEKA Co., LTD.

[0098] The anti-moisture component is selected from GENIOSIL STP E30 provided by Wacker Chemicals;

[0099] The reactive diluent is selected from HELOXY Modifier 65 provided by Heloxy Chemicals;

[0100] The photoinitiator is selected from SilForce UV9380C provided by Momentive Performance Materials Inc.;

[0101] Photoinitiation auxiliary agent is selected from the QC (camphorquinone) of Aladdin;

[0102] Other additives are selected from KH560 (γ-(2,3-epoxypropoxy)propyltrimethoxysilane) provided by Aladdin.

[0103] Preparation method of water vapor resistant composition

[0104] According to the water vapor resistant com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap